In short, Polytetrafluoroethylene (PTFE) is a premier material for laboratory use due to its exceptional chemical inertness, broad thermal stability, and unique non-stick surface. These three core properties, stemming from its strong carbon-fluorine molecular bonds, ensure that labware made from PTFE will not react with sensitive chemicals, fail under extreme temperatures, or interfere with quantitative transfers, thereby protecting the integrity of an experiment.

The true value of PTFE in a laboratory setting lies in its reliability. Its unique combination of chemical, thermal, and surface properties makes it a "go-to" material for minimizing unwanted variables and ensuring experimental results are accurate and repeatable.

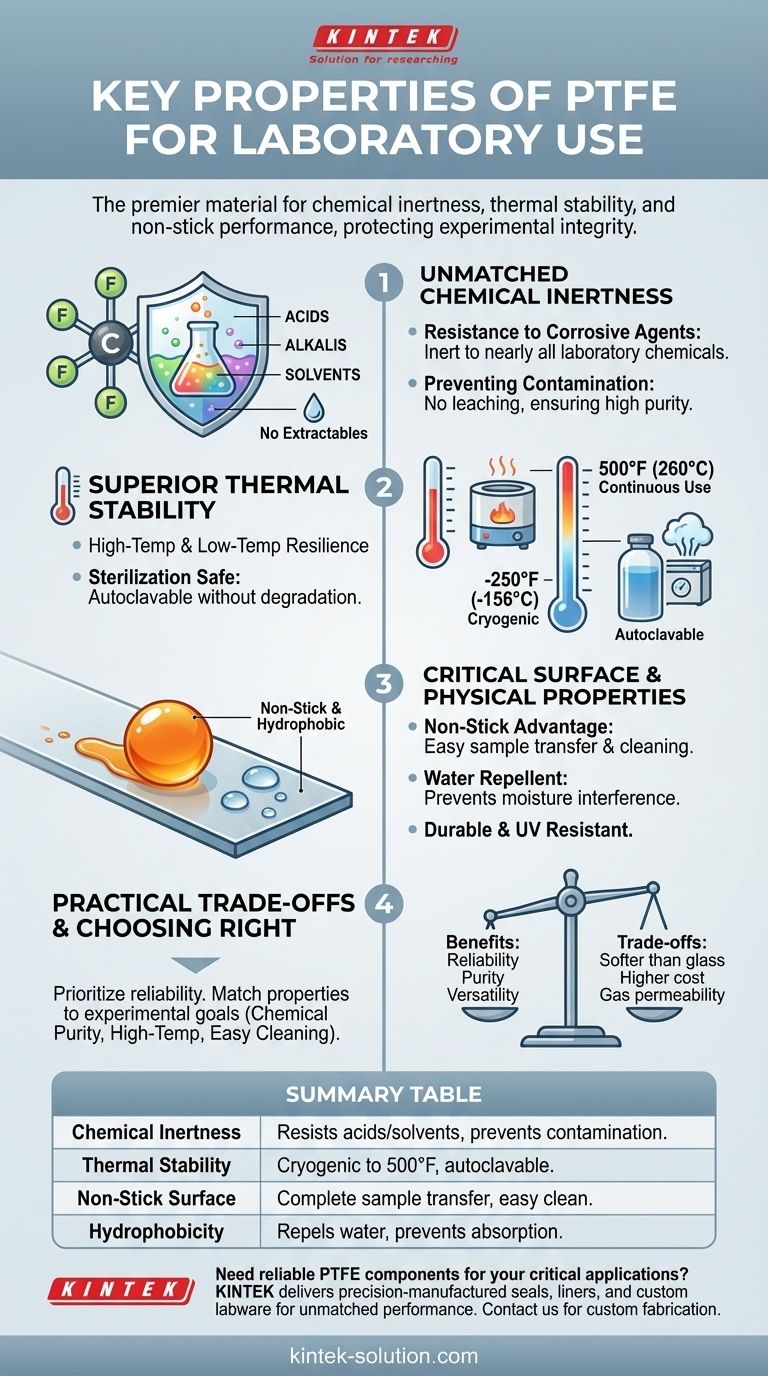

The Foundation: Unmatched Chemical Inertness

The primary reason PTFE is so prevalent in laboratories is its near-total resistance to chemical attack. This property is not a coincidence but a direct result of its molecular structure.

The Role of Carbon-Fluorine Bonds

At its core, PTFE is composed of long chains of carbon atoms completely shielded by a sheath of fluorine atoms. The bond between carbon and fluorine is exceptionally strong and stable, making the molecule highly non-reactive.

Resistance to Corrosive Agents

This robust structure means PTFE is inert to nearly all common laboratory chemicals. It shows extreme resistance to strong acids, alkalis, corrosive agents, and virtually all organic solvents, ensuring it won't degrade when exposed to aggressive substances.

Preventing Contamination

A critical benefit of this inertness is that PTFE is free from extractables. It does not leach chemicals or contaminants into the solutions it holds, which is essential for high-purity applications in analytical chemistry and biology.

Superior Performance Across Extreme Temperatures

Experiments rarely occur at a single room temperature. PTFE’s ability to maintain its integrity across a wide temperature spectrum makes it incredibly versatile.

High-Temperature Stability

PTFE has a very high melting point of around 327°C (621°F) and can be used continuously at temperatures up to 260°C (500°F). This makes it ideal for applications involving heating, from hot plates to high-temperature reactions.

Low-Temperature Resilience

Equally important is its performance in cold environments. PTFE retains its strength, toughness, and flexural properties at cryogenic temperatures, remaining functional in conditions as low as -250°F (-156°C) without becoming brittle.

Autoclavable for Sterilization

For biological and medical labs, sterility is non-negotiable. PTFE is autoclavable, meaning it can be safely sterilized with high-pressure steam without degrading its physical or chemical properties.

Critical Surface and Physical Properties

Beyond its resistance, the physical nature of PTFE's surface provides distinct advantages for lab work that demands precision.

The "Non-Stick" Advantage

PTFE has an extremely low coefficient of friction and low surface tension, making it one of the most well-known "non-stick" materials. In the lab, this means viscous liquids and sticky residues slide off easily, ensuring complete sample transfer and simplifying cleaning.

Hydrophobicity and Water Resistance

PTFE is highly hydrophobic, meaning it actively repels water. This property is crucial for preventing water absorption and ensuring that measurements and reactions are not influenced by retained moisture.

Durability and UV Resistance

While softer than glass, PTFE is an extremely durable and tough material with high flexural strength. It is also opaque and exhibits excellent resistance to degradation from UV light, making it suitable for long-term use and storage.

Understanding the Practical Trade-offs

No material is perfect for every situation. While its benefits are significant, it's important to understand PTFE's limitations to use it effectively.

Mechanical Limitations

PTFE is softer and has lower tensile strength compared to materials like glass or stainless steel. It can be susceptible to "creep" (slow deformation under load) and is more easily scratched, which may be a concern in high-abrasion environments.

Higher Initial Cost

Labware made from PTFE is typically more expensive than its glass or polyethylene counterparts. This cost is an investment in chemical resistance and durability, but it can be a significant factor for budget-conscious labs.

Gas Permeability

While excellent at repelling liquids, PTFE is slightly permeable to certain small gas molecules. This is generally not an issue for most benchtop work but should be considered for long-term storage of sensitive gases or high-vacuum applications.

Making the Right Choice for Your Application

Selecting PTFE is a decision to prioritize reliability and purity in demanding conditions. Use its properties to your advantage by matching them to your experimental goals.

- If your primary focus is chemical purity and preventing reactions: PTFE is the superior choice for handling highly corrosive reagents or running trace analysis where contamination is a critical concern.

- If your primary focus is high-temperature experiments: Its thermal stability makes it ideal for beakers, liners, and tubing used in heating mantles, ovens, or autoclaves.

- If your primary focus is complete sample transfer and easy cleaning: The non-stick surface of PTFE is invaluable when working with viscous, biological, or high-value materials.

Ultimately, PTFE's unique molecular structure provides a powerful combination of resistances that make it an indispensable tool for protecting the integrity of modern scientific research.

Summary Table:

| Key Property | Benefit in the Laboratory |

|---|---|

| Chemical Inertness | Resists virtually all acids, alkalis, and solvents; prevents contamination and leaching. |

| Thermal Stability | Performs from cryogenic (-250°F) to high temperatures (500°F); autoclavable for sterilization. |

| Non-Stick Surface | Ensures complete sample transfer, easy cleaning of viscous or sticky materials. |

| Hydrophobicity | Repels water, preventing moisture absorption that could affect experiments. |

Need reliable PTFE components for your critical applications?

At KINTEK, we understand that the superior properties of PTFE are essential for protecting the integrity of your work in the semiconductor, medical, laboratory, and industrial sectors. Our precision-manufactured PTFE seals, liners, labware, and custom components are engineered to deliver the unmatched chemical resistance, thermal stability, and non-stick performance your experiments demand.

We offer custom fabrication from prototypes to high-volume orders, ensuring you get the exact PTFE solution you need.

Contact us today to discuss your specific requirements and learn how KINTEK's PTFE expertise can enhance your lab's reliability and results.

Visual Guide

Related Products

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What makes the PTFE bottle durable? Unmatched Chemical & Thermal Stability for Demanding Applications

- Why is chemical compatibility important when choosing a PTFE-coated septum? Avoid Sample Contamination and Data Loss

- What are the common characteristics of Teflon? Unlocking Extreme Chemical and Thermal Resistance

- What are the unique properties of PTFE that make it commercially valuable? Unlock Unmatched Performance

- What are some exceptional properties of PTFE? Unlock Unmatched Performance in Extreme Environments