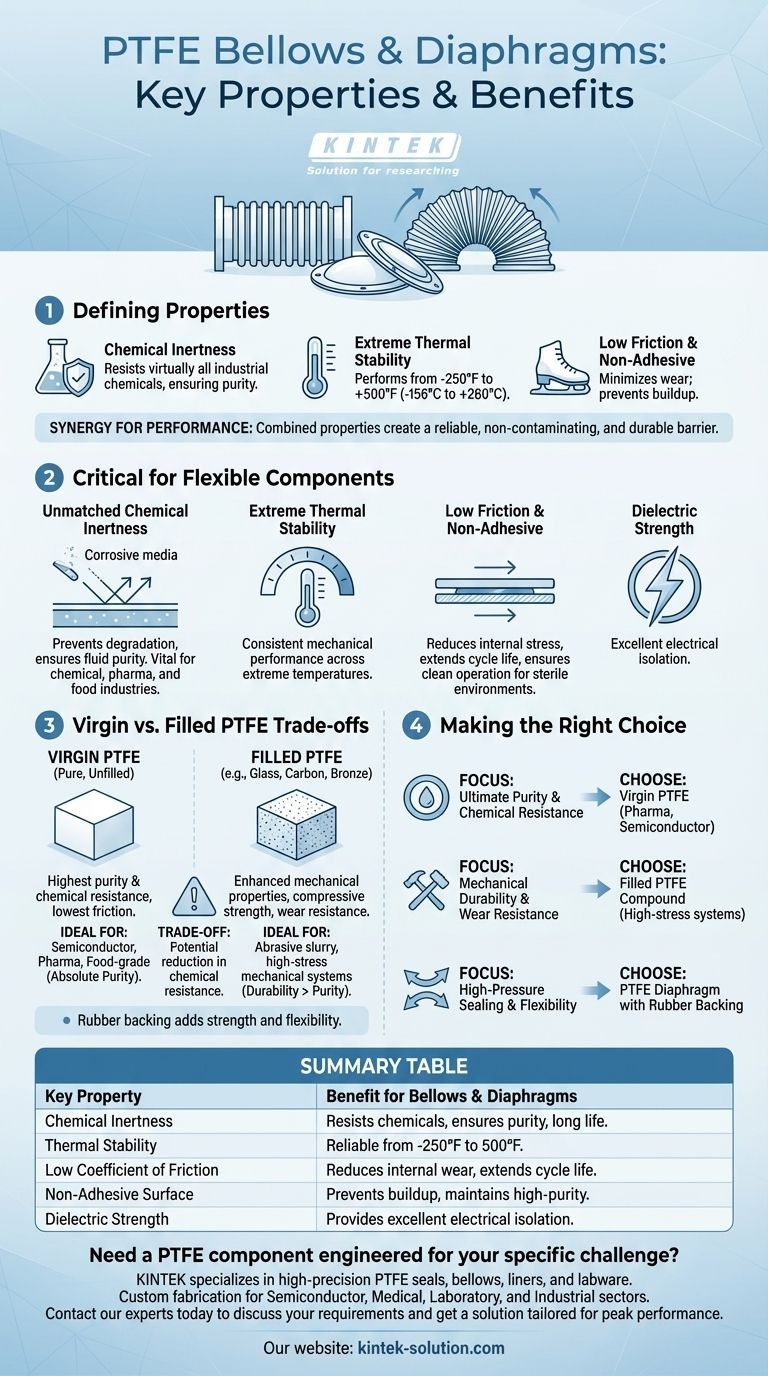

The definitive properties of Polytetrafluoroethylene (PTFE) that make it an exceptional material for bellows and diaphragms are its near-universal chemical inertness, extreme thermal stability, and uniquely low coefficient of friction. These characteristics ensure that components maintain their integrity and performance when exposed to aggressive chemicals, wide temperature ranges, and high-cycle mechanical stress. Its non-adhesive surface and dielectric strength further enhance its value in specialized, high-purity applications.

The core reason PTFE is chosen for critical bellows and diaphragms is not just one property, but the combination of all of them. This synergy creates a reliable, non-contaminating, and durable flexible barrier that consistently outperforms other materials in the most demanding operational environments.

Why These Properties are Critical for Flexible Components

Bellows and diaphragms are not static parts; they are engineered to flex, seal, and isolate media under dynamic conditions. The material they are made from must be able to withstand these demands without degrading.

Unmatched Chemical Inertness

PTFE is inert to nearly all industrial chemicals, including aggressive acids, bases, solvents, and oxidizers. This prevents the material from degrading, swelling, or failing when in contact with corrosive media.

For a diaphragm acting as a barrier, this ensures the purity of the process fluid is maintained and the component itself has a long, reliable service life. This is paramount in chemical processing, pharmaceutical, and food and beverage industries.

Extreme Thermal Stability

PTFE components operate effectively across an exceptionally wide temperature range, typically from -250°F to over 500°F (-156°C to over 260°C).

This stability means a PTFE bellow will not become brittle at cryogenic temperatures or lose its structural integrity in high-heat applications, ensuring consistent mechanical performance.

Exceptionally Low Friction and Non-Adhesive Surface

PTFE has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice. For a flexing component like a bellow, this minimizes internal stress and wear during repeated movement, leading to a longer cycle life.

Furthermore, its non-adhesive surface resists the buildup of process media. This prevents contamination and ensures the system operates cleanly, which is essential for sterile environments in medicine or semiconductor manufacturing.

Dielectric Strength for Electrical Isolation

While not always the primary requirement, PTFE is an excellent electrical insulator. This property is valuable in applications where a component must provide a chemical or pressure seal while also preventing the flow of electric current.

Understanding the Trade-offs: Virgin vs. Filled PTFE

The choice of PTFE is not limited to one type. Understanding the difference between pure (virgin) and filled grades is critical for proper material selection.

The Purity and Performance of Virgin PTFE

Virgin PTFE is pure, unfilled Polytetrafluoroethylene. It offers the highest level of chemical resistance and the lowest coefficient of friction.

This is the non-negotiable choice for applications demanding absolute purity, such as in semiconductor, pharmaceutical, or food-grade systems where any potential contamination from a filler material is unacceptable.

The Mechanical Advantages of Filled PTFE

Fillers like glass, carbon, or bronze can be added to the PTFE matrix to enhance specific mechanical properties. These compounds can offer increased compressive strength, better wear resistance, and improved durability.

A filled PTFE diaphragm might be selected for an abrasive slurry application where mechanical toughness is more critical than absolute chemical purity. These grades can also be a more cost-effective solution.

The Inherent Compromise of Filled Grades

The primary trade-off with filled PTFE is a potential reduction in chemical resistance. The filler material may not be as inert as the PTFE itself, creating a potential point of failure when exposed to highly corrosive media.

Additionally, a rubber backing is sometimes used with a PTFE diaphragm to add strength and resilience, combining PTFE's surface properties with the flexibility of an elastomer.

Making the Right Choice for Your Application

Selecting the correct PTFE material depends entirely on the operational priorities of your system.

- If your primary focus is ultimate purity and chemical resistance: Virgin PTFE is the only reliable choice, especially for pharmaceutical, food, or semiconductor applications.

- If your primary focus is mechanical durability and wear resistance: A filled PTFE compound may offer a longer life cycle in high-stress mechanical systems, provided the reduced chemical resistance is acceptable for your process media.

- If your primary focus is high-pressure sealing and flexibility: A PTFE diaphragm bonded to a rubber backing combines the chemical resistance of the former with the resilience of the latter.

By understanding these core properties and their associated trade-offs, you can select a material precisely engineered for reliability in your most demanding environments.

Summary Table:

| Key Property | Benefit for Bellows & Diaphragms |

|---|---|

| Chemical Inertness | Resists virtually all chemicals, ensuring purity and long service life. |

| Thermal Stability | Performs reliably from -250°F to 500°F (-156°C to 260°C). |

| Low Coefficient of Friction | Reduces internal wear, extending cycle life in dynamic applications. |

| Non-Adhesive Surface | Prevents media buildup and contamination for high-purity processes. |

| Dielectric Strength | Provides excellent electrical isolation in addition to sealing functions. |

Need a PTFE component engineered for your specific challenge?

At KINTEK, we specialize in manufacturing high-precision PTFE seals, bellows, liners, and labware for the semiconductor, medical, laboratory, and industrial sectors. Whether you require the ultimate purity of virgin PTFE or the enhanced durability of a filled compound, our custom fabrication services—from prototypes to high-volume orders—deliver the reliability your critical applications demand.

Contact our experts today to discuss your requirements and get a solution tailored for peak performance.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE and Nitrile Diaphragm Pump Components for Demanding Applications

- Customizable PTFE Crucibles for Laboratory and Industrial Applications

People Also Ask

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions