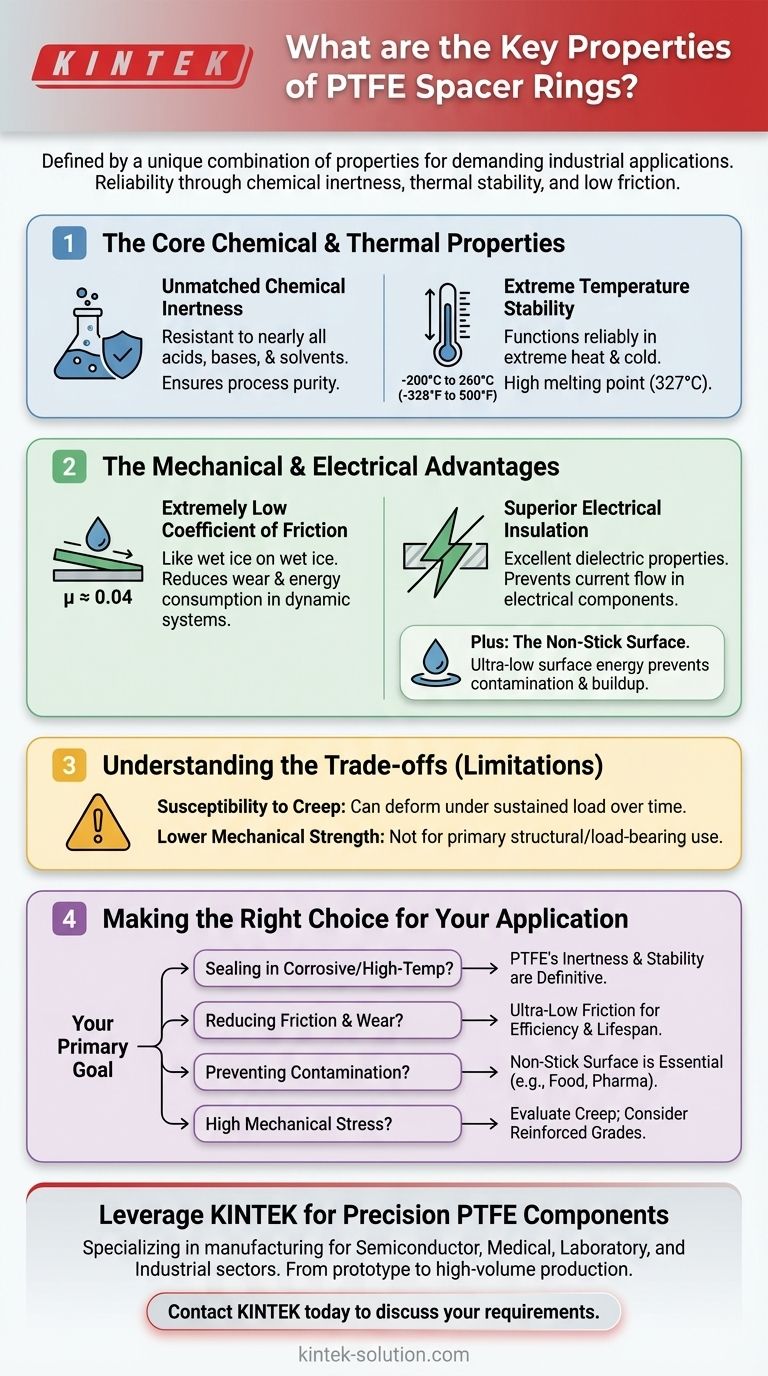

At their core, PTFE spacer rings are defined by a unique combination of properties that make them exceptionally versatile for demanding industrial applications. Their primary characteristics include unparalleled chemical resistance, an extremely low coefficient of friction, a wide operating temperature range, and excellent electrical insulation.

The true value of PTFE lies not in a single property, but in how its chemical inertness, thermal stability, and low-friction nature work together to ensure reliability and longevity in environments where most other materials would quickly fail.

The Core Chemical and Thermal Properties

The foundational strengths of PTFE (polytetrafluoroethylene) are its near-total immunity to chemical attack and its ability to perform across extreme temperatures.

Unmatched Chemical Inertness

PTFE is resistant to nearly all industrial chemicals, including the most aggressive acids, bases, and organic solvents.

This exceptional stability makes it an ideal material for seals and spacers in equipment like reaction kettles and chemical storage tanks, preventing degradation and ensuring process purity.

Extreme Temperature Stability

PTFE functions reliably across a vast temperature spectrum, typically from -200°C to 260°C (-328°F to 500°F).

While its functional limit is around 260°C, it has a very high melting point of 327°C. This allows it to maintain its integrity in applications where other polymers would become brittle or melt.

The Mechanical and Electrical Advantages

Beyond its chemical and thermal resilience, PTFE's physical properties provide distinct advantages in mechanical and electrical systems.

Extremely Low Coefficient of Friction

PTFE has one of the lowest friction coefficients of any solid material, often compared to the friction of wet ice on wet ice (approximately 0.04).

This characteristic is critical for reducing wear and energy consumption in dynamic applications, such as in transmission pipelines or moving machinery, by allowing components to slide past each other with minimal resistance.

Superior Electrical Insulation

PTFE possesses excellent dielectric properties, meaning it does not conduct electricity.

This makes it a superior choice for spacers and insulators in electrical components where preventing the flow of current is a primary requirement.

The Non-Stick Surface

Due to its ultra-low surface energy, almost no substances will adhere to PTFE.

This non-stick quality is vital for preventing contamination, reducing buildup, and ensuring the smooth, consistent operation of components.

Understanding the Trade-offs

While its properties are exceptional, it is crucial to understand the material's limitations to ensure proper application. PTFE is not a universal solution for every engineering challenge.

Susceptibility to Creep

Under sustained compressive loads, PTFE can be susceptible to "creep" or "cold flow," meaning it can slowly deform over time. This must be considered in high-pressure static sealing applications where dimensional stability is critical.

Lower Mechanical Strength

Compared to high-performance engineering plastics like PEEK or metals, PTFE is a relatively soft material with lower tensile strength and rigidity. It is not intended for use as a primary structural or load-bearing component.

Making the Right Choice for Your Application

Selecting the right material requires matching its properties to your primary operational goal.

- If your primary focus is sealing in highly corrosive or high-temperature environments: PTFE's chemical inertness and thermal stability make it the definitive choice.

- If your primary focus is reducing friction and wear in dynamic systems: The ultra-low friction coefficient offers unmatched performance for improving efficiency and component lifespan.

- If your primary focus is preventing contamination or material buildup: PTFE's non-stick surface is essential for applications in the food, pharmaceutical, and semiconductor industries.

- If your application involves high mechanical stress or static loads: You must carefully evaluate the potential for creep and consider reinforced PTFE grades or alternative materials.

Ultimately, understanding these key properties empowers you to leverage PTFE spacer rings for creating more reliable, efficient, and long-lasting systems.

Summary Table:

| Key Property | Description | Key Benefit |

|---|---|---|

| Chemical Inertness | Resistant to nearly all acids, bases, and solvents. | Ensures reliability and purity in corrosive environments. |

| Temperature Stability | Operates from -200°C to 260°C (-328°F to 500°F). | Maintains performance in extreme heat and cold. |

| Low Friction | Extremely low coefficient of friction (~0.04). | Reduces wear and energy consumption in dynamic systems. |

| Electrical Insulation | Excellent dielectric properties. | Ideal for insulating components in electrical applications. |

| Non-Stick Surface | Ultra-low surface energy prevents adhesion. | Prevents contamination and material buildup. |

Leverage the unique properties of PTFE for your critical applications.

Do you need high-performance PTFE spacer rings, seals, liners, or custom labware that can withstand corrosive chemicals, extreme temperatures, and reduce friction? KINTEK specializes in the precision manufacturing of PTFE components for the semiconductor, medical, laboratory, and industrial sectors.

We partner with you from prototype to high-volume production to ensure your components deliver unmatched reliability and longevity.

Contact KINTEB today to discuss your specific requirements and get a quote for your project.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments