The defining properties of PTFE seals and rings are their extreme chemical inertness, an exceptionally wide operating temperature range, and one of the lowest coefficients of friction of any solid material. This unique combination makes PTFE (Polytetrafluoroethylene) a high-performance polymer for demanding applications where other materials would quickly fail due to heat, aggressive media, or friction.

PTFE is best understood as a material of extremes. It offers unparalleled performance in harsh thermal and chemical environments and provides a nearly frictionless surface, but these advantages come with the critical trade-off of low mechanical strength.

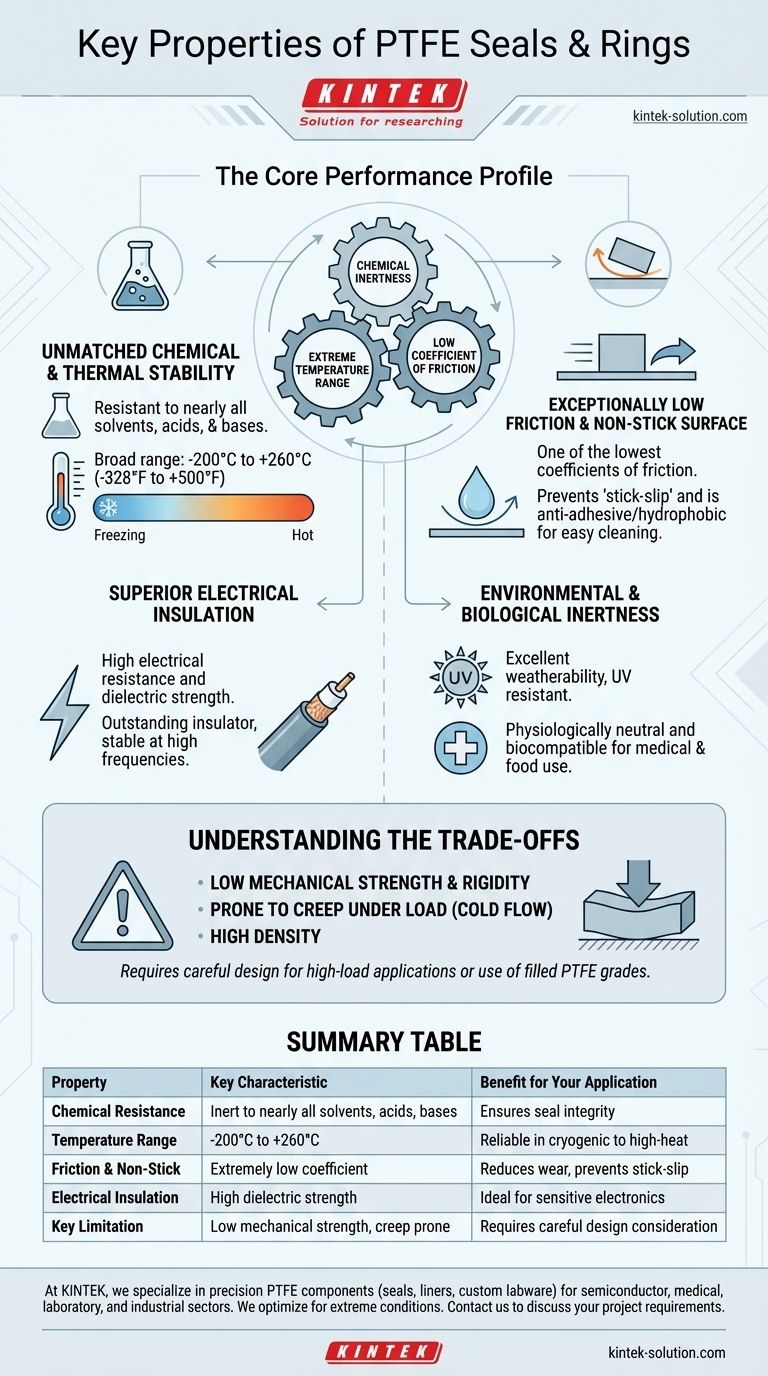

The Core Performance Profile of PTFE

To select PTFE for an application, you must understand how its distinct characteristics translate into real-world performance. These properties are not isolated; they work together to define its role as a problem-solving material.

Unmatched Chemical and Thermal Stability

PTFE seals maintain their integrity in conditions that would destroy most other plastics and elastomers. They are resistant to nearly all common solvents, acids, and bases.

This chemical resistance is maintained across an exceptionally broad temperature range, typically from –200°C to +260°C (–328°F to +500°F). This makes it suitable for everything from cryogenic applications to high-heat industrial processes.

Exceptionally Low Friction and Non-Stick Surface

PTFE has one of the lowest coefficients of friction known, creating a surface that is incredibly slick. This results in excellent sliding properties and prevents the "stick-slip" effect, ensuring smooth, consistent movement in dynamic seals.

Its surface is also anti-adhesive and hydrophobic (water-repelling), which prevents materials from sticking and simplifies cleaning, making it valuable in food processing and medical applications.

Superior Electrical Insulation

With high electrical resistance and high dielectric strength, PTFE is an outstanding electrical insulator. This property is particularly stable even at high radio frequencies.

This makes it an ideal choice for insulating components in electronics, connectors, and high-frequency cables where signal integrity is critical.

Environmental and Biological Inertness

PTFE exhibits excellent weatherability and is highly resistant to degradation from UV radiation, making it suitable for long-term outdoor use.

Furthermore, it is physiologically neutral and biocompatible within its normal operating temperatures. This inertness makes it a trusted material for seals and components in medical devices and food-grade equipment.

Understanding the Trade-offs

While PTFE's performance is exceptional in many areas, its primary limitations are mechanical. Ignoring these can lead to component failure.

Low Mechanical Strength and Rigidity

The most significant drawback of pure PTFE is its low mechanical strength, rigidity, and tensile strength. It is a relatively soft material.

Under sustained compressive loads, PTFE can be prone to creep, or cold flow, where the material slowly deforms over time. This limits its use in high-load structural applications where dimensional stability is paramount.

High Density

PTFE is also one of the densest plastics, with a density up to 2.2 g/cm³. While not always a limitation, this higher weight-to-volume ratio must be factored into designs where component weight is a critical parameter.

Making the Right Choice for Your Application

Your final material decision should be based on the primary challenge you need to solve.

- If your primary focus is sealing against aggressive chemicals or extreme temperatures: PTFE is an industry-leading choice due to its near-universal chemical resistance and vast thermal range.

- If your primary focus is reducing friction in a dynamic system: The exceptionally low friction coefficient of PTFE provides a self-lubricating surface that minimizes wear and energy loss.

- If your primary focus is high-frequency electrical insulation: PTFE's stable dielectric properties make it a superior material for insulating sensitive electronic components.

- If your primary focus is supporting a significant mechanical load: You must proceed with caution, as pure PTFE's low strength may require design modifications or the use of filled PTFE grades.

Choosing the right seal material is about aligning its unique strengths with the specific demands of your application.

Summary Table:

| Property | Key Characteristic | Benefit for Your Application |

|---|---|---|

| Chemical Resistance | Inert to nearly all solvents, acids, and bases | Ensures seal integrity in aggressive chemical processes |

| Temperature Range | Performs from -200°C to +260°C (-328°F to +500°F) | Reliable operation in cryogenic to high-heat environments |

| Friction & Non-Stick | Extremely low coefficient of friction; anti-adhesive | Reduces wear, prevents stick-slip, and eases cleaning |

| Electrical Insulation | High dielectric strength, stable at high frequencies | Ideal for sensitive electronics and high-frequency cables |

| Key Limitation | Low mechanical strength and prone to creep under load | Requires careful design consideration for high-load applications |

Need PTFE seals that deliver unmatched performance in your most demanding applications?

At KINTEK, we specialize in the precision manufacturing of PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and specialized industrial sectors. We understand that your success depends on components that can withstand extreme temperatures, aggressive chemicals, and require minimal friction.

Our expertise ensures you get components that are not just made to specification, but are optimized for your specific operational challenges. We offer custom fabrication from prototypes to high-volume orders, guaranteeing the precision and reliability your applications demand.

Let's engineer a solution for you. Contact our team today to discuss your project requirements.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- Why is PTFE considered a significant discovery? A Material That Revolutionized Industry

- What is the hardness range of PTFE on the Shore D scale? Leveraging Its Softness for Superior Performance

- How is PTFE used in industrial processes? Maximize Safety and Efficiency

- What are some important physical property values for PTFE? Master Its Extreme Performance for Demanding Applications

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications