At its core, Polytetrafluoroethylene (PTFE) is a high-performance fluoropolymer defined by three cornerstone properties: an extremely low coefficient of friction, exceptional chemical inertness, and a remarkably wide operating temperature range. This unique combination makes it a material of choice for some of the most demanding engineering environments where conventional plastics and even metals would fail.

The true value of PTFE isn't just one of its standout properties, but its ability to deliver all of them simultaneously. It solves complex problems by providing a surface that is incredibly slippery, chemically resistant, and stable across extreme temperatures, all at the same time.

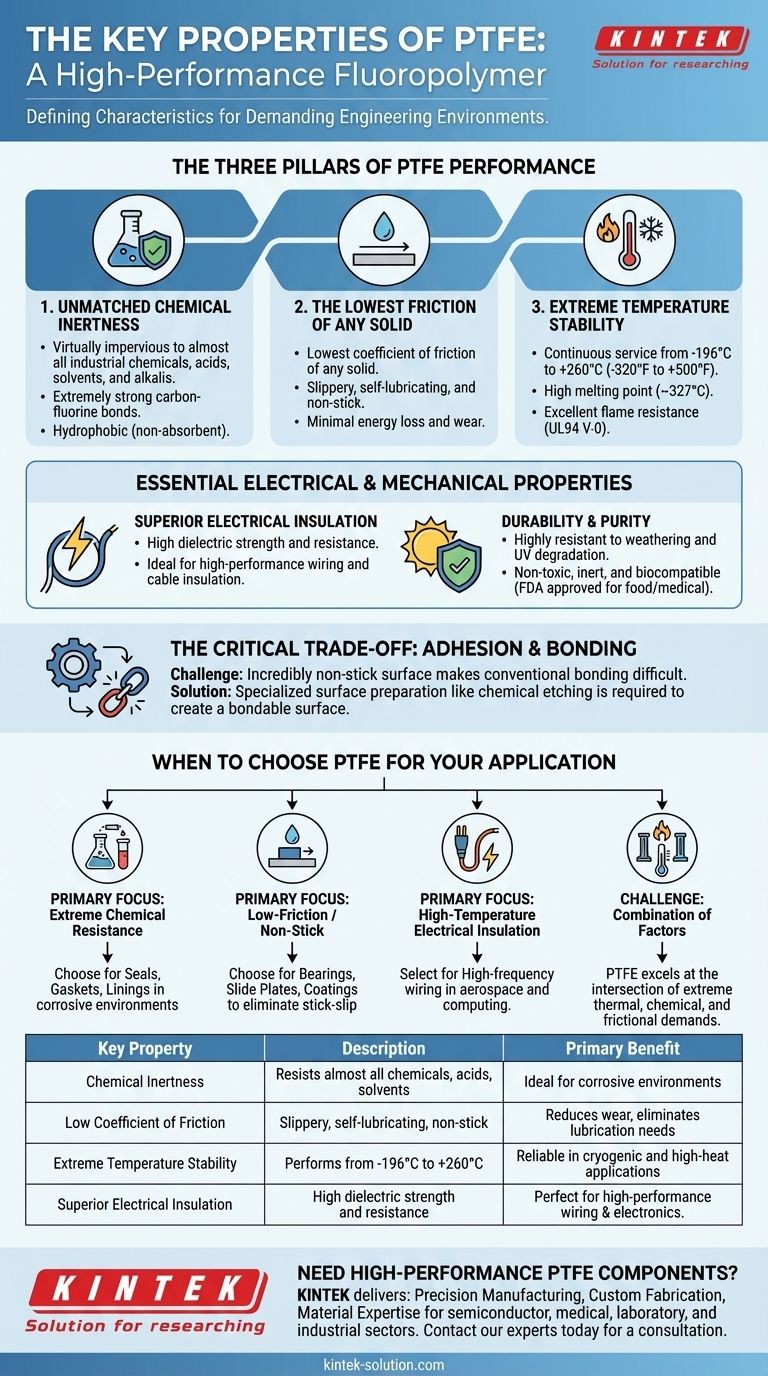

The Three Pillars of PTFE Performance

To understand if PTFE is the right material for your application, you must first appreciate the interplay of its three primary characteristics.

1. Unmatched Chemical Inertness

PTFE is one of the most non-reactive substances known. This is due to the incredibly strong carbon-fluorine bonds that make up its molecular structure, which are extremely difficult for other chemicals to break.

This property makes PTFE virtually impervious to attack from almost all industrial chemicals, acids, solvents, and alkalis. It is also hydrophobic, meaning it does not absorb water.

2. The Lowest Friction of Any Solid

PTFE has the lowest known coefficient of friction of any solid material, making it one of the most slippery substances in existence—even more so than wet ice on wet ice.

This results in its famous non-stick and self-lubricating qualities. Components made from PTFE can operate smoothly against other surfaces with minimal energy loss or wear, often eliminating the need for external lubricants.

3. Extreme Temperature Stability

PTFE performs reliably across an exceptionally broad thermal range. It maintains its properties in continuous service at temperatures up to +260°C (+500°F).

Crucially, it also retains its strength, toughness, and flexibility at cryogenic temperatures as low as -196°C (-320°F). It also has a very high melting point of around 327°C and exhibits excellent flame resistance with a UL94 V-0 rating.

Essential Electrical and Mechanical Properties

Beyond the core three, several other characteristics make PTFE a versatile engineering material.

Superior Electrical Insulation

PTFE is an excellent electrical insulator with very high dielectric strength and high electrical resistance. It effectively prevents the flow of electricity, making it ideal for high-performance wiring and cable insulation, especially in applications where temperature and chemical resistance are also required.

Durability and Purity

The material is highly resistant to weathering and degradation from UV light, ensuring long-term stability in outdoor applications.

Furthermore, many grades of PTFE are non-toxic, inert, and biocompatible. This has led to its approval by the FDA for use in food processing and medical applications.

The Critical Trade-off: Adhesion and Bonding

While PTFE's properties are exceptional, they create one significant limitation that is critical to understand.

The Challenge of Non-Stick

The same chemical inertness and low surface energy that make PTFE incredibly non-stick also make it extremely difficult to bond to other materials using conventional adhesives.

Overcoming the Limitation

Specialized surface preparation, such as chemical etching, is almost always required to create a bondable surface on PTFE. This process modifies the surface chemistry, allowing adhesives to gain a foothold. This is a critical design consideration if your application requires gluing or bonding PTFE to another substrate.

When to Choose PTFE for Your Application

Use this framework to determine if PTFE is the appropriate solution for your specific goal.

- If your primary focus is extreme chemical resistance: Choose PTFE for seals, gaskets, linings, and components that will be exposed to aggressive or corrosive chemicals.

- If your primary focus is low-friction or a non-stick surface: Use PTFE for self-lubricating bearings, slide plates, or as a coating for equipment where stick-slip must be eliminated.

- If your primary focus is high-temperature electrical insulation: Select PTFE for high-frequency or high-temperature wiring in aerospace, computing, and demanding industrial applications.

- If your challenge involves a combination of these factors: This is where PTFE truly excels. Use it for components that must function in an environment that is simultaneously hot, corrosive, and requires low friction.

Ultimately, PTFE is the definitive engineering choice for applications operating at the intersection of extreme thermal, chemical, and frictional demands.

Summary Table:

| Key Property | Description | Primary Benefit |

|---|---|---|

| Chemical Inertness | Resists almost all industrial chemicals, acids, and solvents. | Ideal for corrosive environments. |

| Low Coefficient of Friction | Extremely slippery, self-lubricating, and non-stick. | Reduces wear and eliminates lubrication needs. |

| Extreme Temperature Stability | Performs from -196°C to +260°C (-320°F to +500°F). | Reliable in both cryogenic and high-heat applications. |

| Superior Electrical Insulation | High dielectric strength and resistance. | Perfect for high-performance wiring and electronics. |

Need High-Performance PTFE Components?

PTFE's unique combination of properties makes it the ideal material for solving complex challenges in the semiconductor, medical, laboratory, and industrial sectors. Whether you need standard parts or custom-designed solutions, KINTEK has the expertise.

We deliver:

- Precision Manufacturing: From prototypes to high-volume production.

- Custom Fabrication: Seals, liners, labware, and more, tailored to your exact specifications.

- Material Expertise: Ensuring your components perform reliably in the most demanding environments.

Let's discuss how our PTFE components can enhance your application. Contact our experts today for a consultation.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications