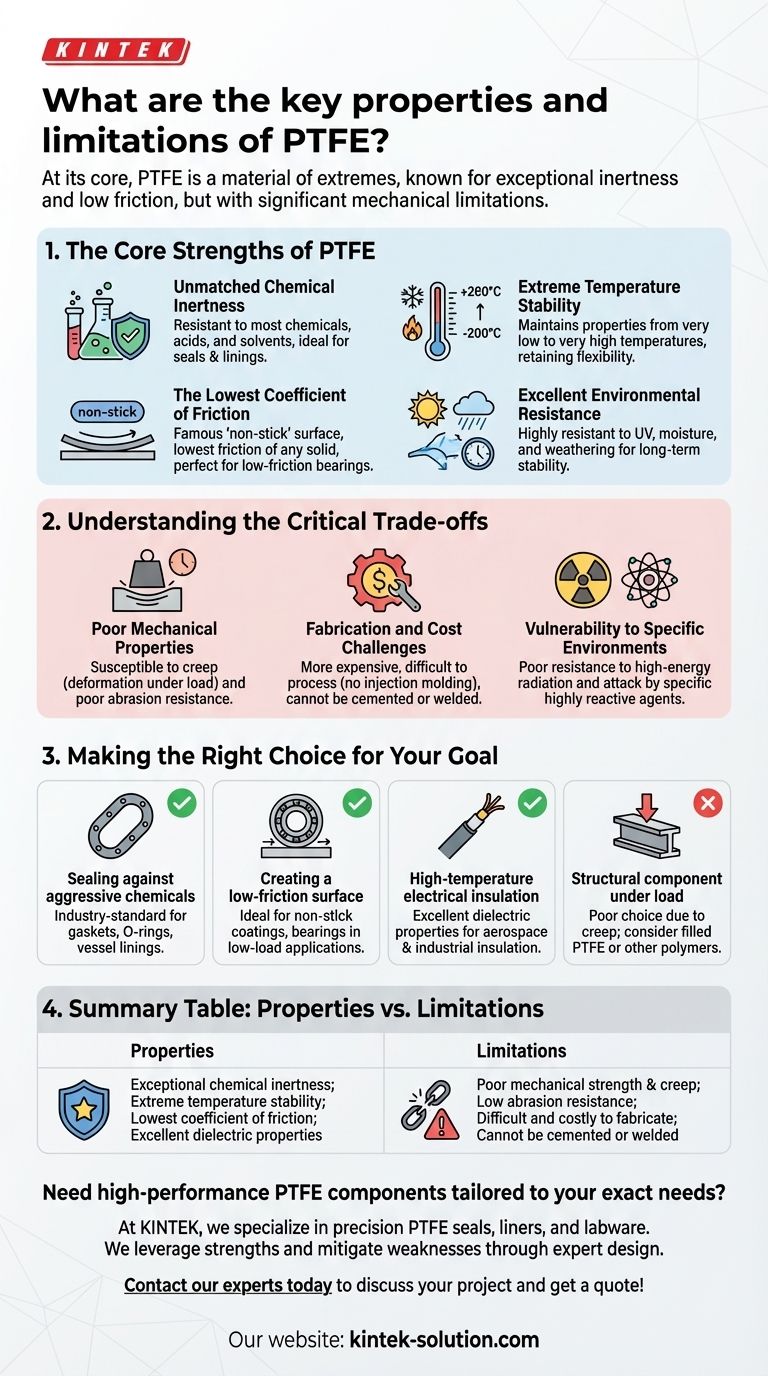

At its core, Polytetrafluoroethylene (PTFE) is a material of extremes. It is renowned for its exceptional chemical inertness, stability across a wide temperature range, and an incredibly low coefficient of friction, making it one of the most non-stick materials known. However, these unique strengths are balanced by significant limitations, including poor mechanical properties under load, sensitivity to abrasion, and challenges in processing and fabrication.

PTFE is an elite specialty polymer, unmatched in environments requiring chemical, thermal, and low-friction performance. Its primary weakness is mechanical; it deforms easily under load, making it unsuitable for most structural applications without reinforcement.

The Core Strengths of PTFE

PTFE's properties stem from the strong carbon-fluorine bonds in its molecular structure. This creates a material that is uniquely resilient in specific environments.

Unmatched Chemical Inertness

PTFE is resistant to the vast majority of chemicals, acids, and solvents, even at elevated temperatures. This makes it an ideal material for seals, gaskets, and linings in chemical processing equipment.

It is so non-reactive that it is frequently used to store and transport highly corrosive materials that would degrade most other plastics and even some metals.

Extreme Temperature Stability

The material has a very high melting point, around 326°C, allowing it to maintain its properties in high-heat applications.

Critically, it also retains its flexibility at very low temperatures, a quality many other polymers lack. This gives it an exceptionally wide and effective operating temperature range.

The Lowest Coefficient of Friction

Often marketed as Teflon, PTFE's surface is famously "non-stick." It possesses one of the lowest coefficients of friction of any solid material.

This property is invaluable for applications like low-friction bearings, non-stick coatings on cookware, and creating surfaces where easy release or smooth movement is required.

Excellent Environmental Resistance

PTFE is highly resistant to degradation from UV radiation, moisture (it is non-wetting), and general weathering. This ensures long-term stability and performance in exposed applications.

Understanding the Critical Trade-offs

Choosing PTFE requires a clear understanding of its significant limitations. Ignoring these can lead to material failure.

Poor Mechanical Properties

This is PTFE's most significant weakness. Despite its durability in other areas, it is mechanically soft and lacks sturdiness under pressure.

It is highly susceptible to creep, which is the tendency for a material to deform permanently over time when under a sustained load. It also has poor abrasion resistance, meaning it wears down quickly from friction with rougher surfaces.

Fabrication and Cost Challenges

PTFE is more expensive than many other polymers and is notoriously difficult to process. It cannot be easily mass-produced using common methods like injection molding.

Furthermore, it cannot be cemented or welded like other plastics, which complicates the assembly of complex parts.

Vulnerability to Specific Environments

While chemically inert in most situations, PTFE does have a few specific weaknesses.

It has poor resistance to high-energy radiation, which can cause its molecular structure to break down. It can also be attacked by a few highly reactive chemical agents, such as elemental fluorine and certain molten alkali metals, under specific conditions of high temperature and pressure.

Making the Right Choice for Your Goal

Selecting PTFE is about matching its unique profile to a specific engineering need. It is rarely a general-purpose solution.

- If your primary focus is sealing against aggressive chemicals: PTFE is an industry-standard choice for gaskets, O-rings, and vessel linings where chemical compatibility is paramount.

- If your primary focus is creating a low-friction surface: It is the ideal material for non-stick coatings and bearings in low-load, low-speed applications.

- If your primary focus is high-temperature electrical insulation: Its thermal stability and dielectric properties make it excellent for insulating wires and cables in demanding aerospace or industrial environments.

- If your primary focus is a structural component under load: PTFE is a poor choice and will likely fail due to creep; you should consider a filled PTFE grade or a different engineering polymer entirely.

By understanding both its exceptional resilience and its mechanical fragility, you can leverage PTFE's unique capabilities precisely where they deliver the most value.

Summary Table:

| Properties | Limitations |

|---|---|

| Exceptional chemical inertness | Poor mechanical strength & creep |

| Extreme temperature stability (-200°C to +260°C) | Low abrasion resistance |

| Lowest coefficient of friction | Difficult and costly to fabricate |

| Excellent dielectric properties | Cannot be cemented or welded |

Need high-performance PTFE components tailored to your exact needs?

At KINTEK, we specialize in manufacturing precision PTFE seals, liners, and labware for the semiconductor, medical, laboratory, and industrial sectors. We understand how to leverage PTFE's strengths while mitigating its weaknesses through expert design and custom fabrication.

Whether you require prototypes or high-volume orders, we deliver components that meet the highest standards of chemical resistance, thermal stability, and performance.

Contact our experts today to discuss your project and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications