At their core, spiral PTFE backup rings are defined by two primary characteristics: their continuous, helical coil construction and the high-performance properties of the Polytetrafluoroethylene (PTFE) material they are made from. This combination creates a gapless, resilient ring that provides uniform pressure distribution and excels at preventing O-ring failure in high-pressure, high-temperature, and chemically aggressive applications.

The central challenge in many sealing systems is preventing the O-ring from being forced, or "extruding," into the clearance gap under high pressure. A spiral PTFE backup ring solves this problem by providing a strong, low-friction, and gapless physical barrier that supports the O-ring.

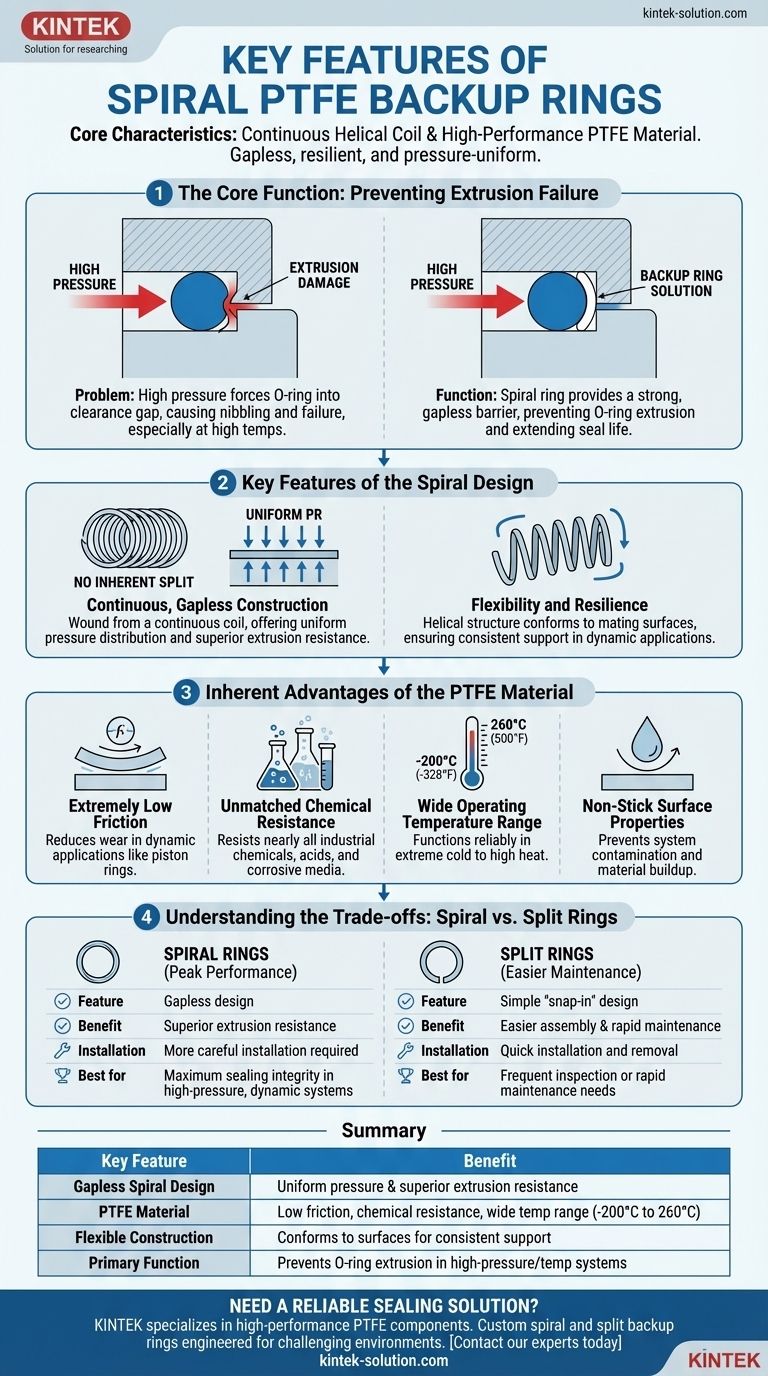

The Core Function: Preventing Extrusion Failure

The primary purpose of any backup ring is to extend the operational life and pressure rating of a simpler seal, like a rubber O-ring.

The Problem with High Pressure

When a sealing system is subjected to high pressure, the O-ring can be physically forced into the small gap between the moving and stationary parts.

This process, known as extrusion, quickly damages the O-ring, leading to nibbling, tearing, and eventual seal failure. High temperatures soften the O-ring material, making this problem significantly worse.

The Backup Ring Solution

A backup ring is installed on the low-pressure side of the O-ring. It fits tightly within the gland and is strong enough to resist deforming under pressure.

By physically blocking the clearance gap, the backup ring provides support and prevents the O-ring material from extruding, dramatically increasing the pressure and temperature limits of the entire sealing system.

Key Features of the Spiral Design

The unique helical shape of a spiral backup ring provides distinct mechanical advantages over simpler, single-turn split rings.

Continuous, Gapless Construction

Because it is wound from a continuous coil of PTFE, a spiral backup ring has no inherent split or gap.

This gapless design ensures a more uniform pressure distribution along the sealing surface, offering the most reliable protection against extrusion in demanding environments.

Flexibility and Resilience

The helical structure gives the ring a natural flexibility and resilience.

This allows it to conform effectively to mating surfaces, even under the dynamic motion found in reciprocating or rotating applications, ensuring consistent support for the O-ring.

Inherent Advantages of the PTFE Material

The choice of PTFE as the material provides a powerful set of properties that make these rings suitable for the most challenging operating conditions.

Extremely Low Friction

PTFE has one of the lowest coefficients of friction of any solid material. This makes it an ideal choice for dynamic applications like piston rings and bearings, where reducing friction and wear is critical.

Unmatched Chemical Resistance

PTFE exhibits exceptional chemical stability, resisting damage from nearly all industrial chemicals, acids, and corrosive media, even at elevated temperatures.

Wide Operating Temperature Range

These rings function reliably across an exceptionally broad temperature spectrum, from cryogenic lows of -200°C (-328°F) up to high-temperature service at 260°C (500°F).

Non-Stick Surface Properties

Almost no substances adhere to a PTFE surface. This non-stick quality is valuable in preventing system contamination and material buildup on the seal.

Understanding the Trade-offs: Spiral vs. Split Rings

While spiral rings offer peak performance, they are not the only option. The choice between a spiral and a simpler split backup ring involves clear trade-offs.

Sealing Performance

For the most demanding, high-pressure environments, the gapless design of a spiral ring provides superior extrusion resistance. A split ring has a small, built-in gap that can be a potential (though minor) extrusion path.

Installation and Maintenance

Split PTFE rings are significantly easier to install and remove. Their simple design allows them to be snapped into place quickly, which facilitates faster assembly, inspection, and maintenance.

A spiral ring’s continuous coil requires more careful installation to ensure it is properly seated without being damaged or over-stretched.

Making the Right Choice for Your Application

The decision between a spiral and a split PTFE backup ring should be driven by the specific demands of your sealing system.

- If your primary focus is maximum sealing integrity in a high-pressure, dynamic system: The continuous, gapless design of the spiral ring is the superior choice.

- If your primary focus is ease of installation, frequent inspection, or rapid maintenance: The simple "snap-in" design of a split backup ring offers significant practical advantages.

- If your primary focus is chemical compatibility or extreme temperatures: Both spiral and split PTFE rings are excellent choices due to the material's inherent high-performance properties.

Ultimately, understanding these key features allows you to select the precise component that balances performance requirements with operational reality.

Summary Table:

| Key Feature | Benefit |

|---|---|

| Gapless Spiral Design | Provides uniform pressure distribution and superior extrusion resistance. |

| PTFE Material | Offers low friction, chemical resistance, and a wide temperature range (-200°C to 260°C). |

| Flexible Construction | Conforms to surfaces for consistent support in dynamic applications. |

| Primary Function | Prevents O-ring extrusion failure in high-pressure and high-temperature systems. |

Need a reliable sealing solution for demanding applications?

KINTEK specializes in the precision manufacturing of high-performance PTFE components, including custom spiral and split backup rings. Our seals are engineered to protect your O-rings from extrusion in the most challenging environments—from high-pressure hydraulic systems to chemically aggressive and high-temperature processes in the semiconductor, medical, and industrial sectors.

We offer custom fabrication from prototypes to high-volume orders, ensuring you get the exact seal you need for optimal performance and longevity.

Contact our experts today to discuss your specific requirements and request a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance