At its core, a custom Teflon part is defined by four key features. These are its high chemical resistance, an exceptionally low coefficient of friction, stability across a wide range of temperatures, and its performance as an excellent electrical insulator. These properties combine to make it a uniquely versatile material for demanding applications.

The true value of custom Teflon (PTFE) parts isn't just one of its features, but the combination of all four. However, successfully designing with this material requires a deep understanding of its unique mechanical behaviors, such as its tendency to expand with heat and deform under pressure.

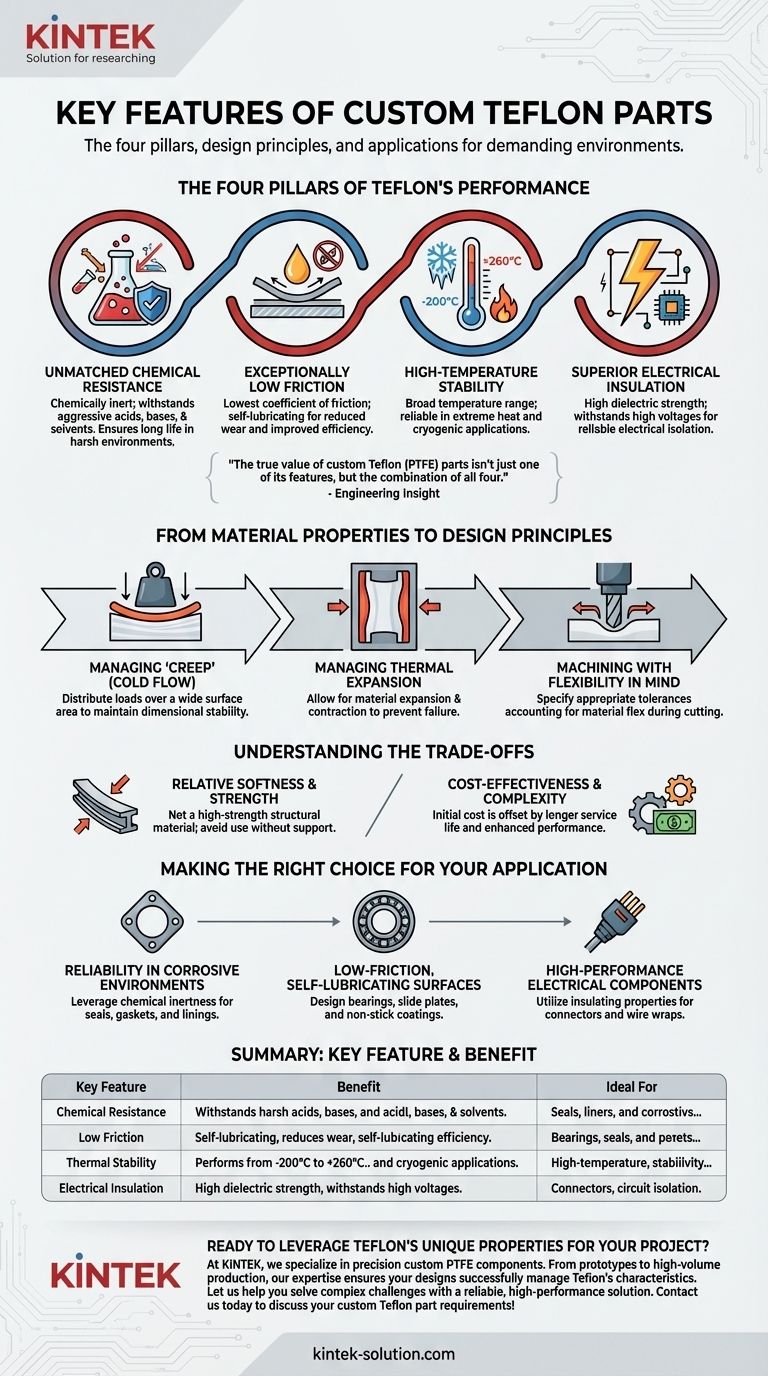

The Four Pillars of Teflon's Performance

To properly leverage custom Teflon parts, you must understand the fundamental properties that drive their performance. These four pillars are what engineers rely on when solving complex challenges.

Unmatched Chemical Resistance

Teflon, or Polytetrafluoroethylene (PTFE), is one of the most chemically inert substances known.

This means it can withstand aggressive acids, bases, and solvents that would degrade most other materials, ensuring a long service life in harsh chemical environments.

Exceptionally Low Friction

Teflon has one of the lowest coefficients of friction of any solid material, giving it its famous "non-stick" quality.

This property is critical for applications like bearings, seals, and gears where self-lubrication is needed to reduce wear and improve efficiency.

High-Temperature Stability

This material maintains its integrity over a very broad temperature range, typically from -200°C to +260°C (-328°F to +500°F).

This thermal stability makes it a reliable choice for components used in extreme heat or cryogenic applications where other polymers would fail.

Superior Electrical Insulation

Teflon is an outstanding electrical insulator with a high dielectric strength, meaning it can withstand high voltages without breaking down.

This makes it an essential material for connectors, cable insulation, and circuit boards where reliable electrical isolation is non-negotiable.

From Material Properties to Design Principles

Knowing the properties of Teflon is only the first step. Creating a successful custom part means designing with its specific mechanical behaviors in mind.

The Challenge of 'Creep' (Cold Flow)

Teflon is a relatively soft material that can slowly deform or "creep" over time if subjected to a constant load.

To prevent this, designs must distribute loads over a wide surface area. This reduces concentrated pressure and maintains the part's dimensional stability.

Managing Thermal Expansion

Teflon expands and contracts with temperature changes more than most metals. This is a critical design consideration.

Your design must allow for this material expansion and contraction. Failure to do so can cause part failure, especially when Teflon is mated with metal components.

Machining with Flexibility in Mind

Because Teflon is a soft and flexible polymer, it behaves differently during machining than rigid plastics or metals.

It is essential to specify appropriate tolerances that account for the material's tendency to flex during cutting, ensuring the final part meets its functional requirements.

Understanding the Trade-offs

No material is perfect. Acknowledging Teflon's limitations is key to using it effectively and avoiding design failures.

Relative Softness and Strength

While chemically durable, Teflon is not a high-strength structural material. It has a lower tensile strength and is more susceptible to creep than engineering metals.

It should not be used for applications requiring high structural rigidity without proper support or reinforcement.

Cost-Effectiveness and Complexity

The raw material and specialized machining required for custom Teflon parts can make them more costly than components made from common plastics.

However, this initial cost is often offset by a longer service life and enhanced performance, especially in conditions where other materials would quickly fail.

Making the Right Choice for Your Application

Your specific goal will determine which of Teflon's features are most critical to your design.

- If your primary focus is reliability in corrosive environments: Leverage its chemical inertness for seals, gaskets, and linings that will last.

- If your primary focus is creating low-friction, self-lubricating surfaces: Design bearings, slide plates, or non-stick coatings that benefit from its low coefficient of friction.

- If your primary focus is high-performance electrical components: Utilize its superior insulating properties for connectors and wire wraps in demanding electronic applications.

Understanding these core features and design principles empowers you to engineer custom Teflon parts that solve problems, not create them.

Summary Table:

| Key Feature | Benefit | Ideal For |

|---|---|---|

| Chemical Resistance | Withstands harsh acids, bases, and solvents | Seals, liners, labware in corrosive environments |

| Low Friction | Self-lubricating, reduces wear | Bearings, seals, slide plates |

| Thermal Stability | Performs from -200°C to +260°C | High-temperature and cryogenic applications |

| Electrical Insulation | High dielectric strength, reliable isolation | Connectors, circuit boards, wire insulation |

Ready to leverage Teflon's unique properties for your project?

At KINTEK, we specialize in manufacturing precision custom PTFE components—from prototypes to high-volume production. Our expertise ensures your designs for the semiconductor, medical, laboratory, and industrial sectors successfully manage Teflon's characteristics like creep and thermal expansion.

Let us help you solve complex challenges with a reliable, high-performance solution.

Contact us today to discuss your custom Teflon part requirements!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications