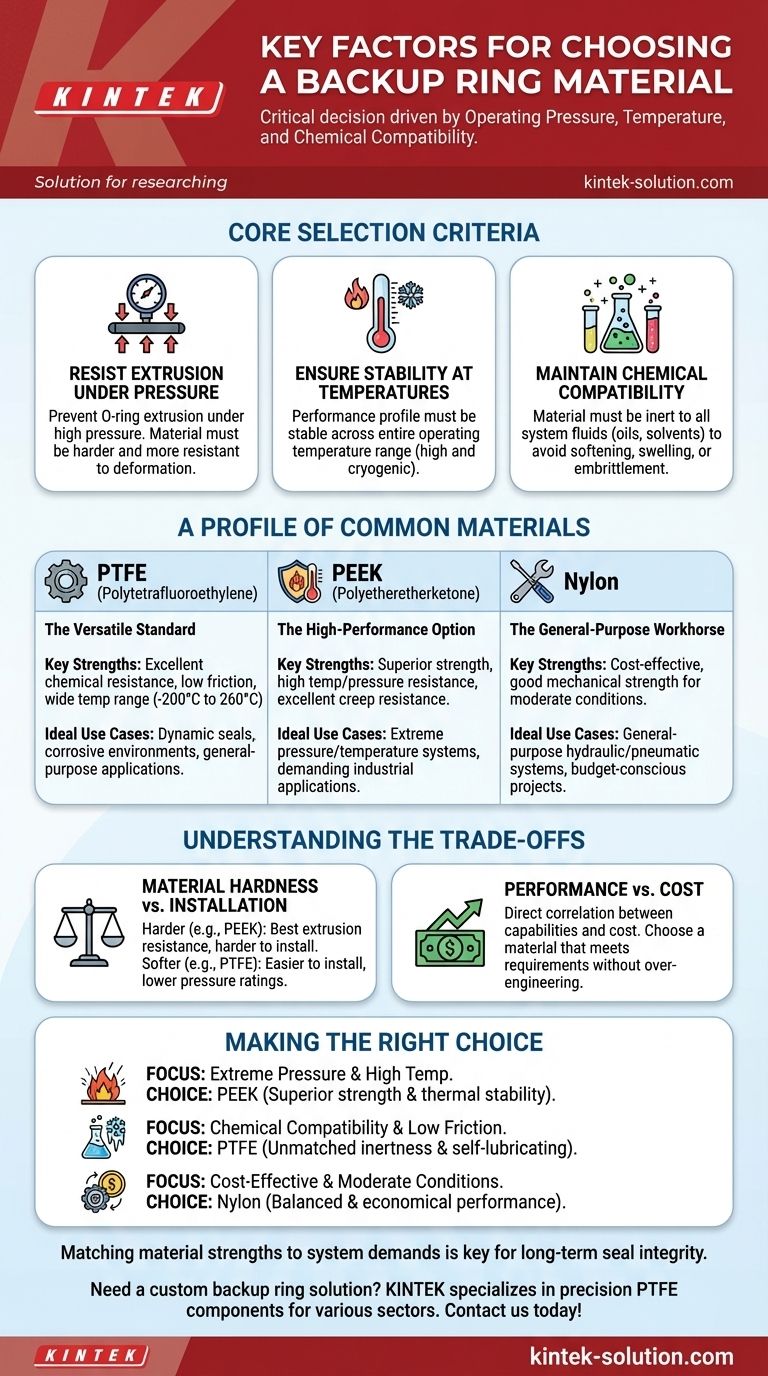

Choosing the right backup ring material is a critical decision driven by three primary factors: operating pressure, temperature, and chemical compatibility. While materials like PEEK and Nylon serve specific high-performance or general-purpose roles, Polytetrafluoroethylene (PTFE) is often the standard due to its exceptional versatility and robust properties.

The function of a backup ring is to prevent O-ring extrusion under high pressure. Therefore, your choice isn't just about finding a material that survives the environment, but selecting one with the necessary hardness and extrusion resistance for your specific pressure and temperature, while remaining compatible with system fluids.

Core Selection Criteria Explained

A backup ring acts as a support structure, physically blocking the O-ring from being forced into the clearance gap between hardware components. The material's ability to perform this function depends entirely on the operating environment.

Resisting Extrusion Under Pressure

Pressure is the primary reason backup rings are necessary. As system pressure increases, the force on the O-ring intensifies, raising the risk of extrusion.

The backup ring material must be significantly harder and more resistant to deformation than the O-ring it supports. This ensures it holds its shape and keeps the clearance gap closed.

Ensuring Stability at Operating Temperatures

Temperature dramatically affects material properties. A material that is hard and robust at room temperature may soften and lose its extrusion resistance at elevated temperatures.

Conversely, some materials can become brittle at cryogenic temperatures. It is crucial to select a material with a stable performance profile across your entire expected operating temperature range.

Maintaining Chemical Compatibility

The backup ring material must be inert to any fluids it will encounter, such as hydraulic oils, solvents, or other chemicals.

Chemical attack can cause a material to soften, swell, or become brittle, leading to a complete failure of its support function and subsequent seal leakage.

A Profile of Common Materials

While many polymers can be used, three materials dominate the field, each with a distinct profile of strengths and ideal use cases.

PTFE (Polytetrafluoroethylene): The Versatile Standard

PTFE is the most common backup ring material due to its exceptional balance of properties. It has an extremely low coefficient of friction, making it ideal for dynamic applications where it reduces wear.

Its chemical stability is nearly universal, resisting almost all industrial chemicals. Furthermore, PTFE operates effectively across a vast temperature range, from -200°C to 260°C (-328°F to 500°F).

PEEK (Polyetheretherketone): The High-Performance Option

PEEK is specified for the most demanding applications involving extreme pressure and high temperatures that exceed the capabilities of PTFE.

It offers superior mechanical strength, stiffness, and creep resistance, ensuring maximum anti-extrusion performance under severe service conditions.

Nylon: The General-Purpose Workhorse

Nylon serves as a cost-effective solution for moderate-duty hydraulic and pneumatic applications.

It provides good extrusion resistance and mechanical strength in standard temperature and pressure ranges where chemical exposure is not a primary concern.

Understanding the Trade-offs

Selecting a material is rarely a matter of finding a single "best" option. It's about understanding the compromises inherent in each choice.

Material Hardness vs. Installation

Harder, more rigid materials like PEEK provide the best extrusion resistance but can be more difficult to install, especially in solid, single-piece ring designs.

Softer, more flexible materials like PTFE are much easier to install but have lower pressure ratings compared to PEEK.

Performance vs. Cost

There is a direct correlation between a material's performance capabilities and its cost. High-performance materials like PEEK are significantly more expensive than standard options.

The goal is to choose a material that reliably meets the application's requirements without over-engineering and incurring unnecessary expense.

The "One-Size-Fits-All" Myth

No single material is the universal solution. A material that excels in one area may be unsuitable for another.

PTFE's excellent chemical resistance is invaluable in corrosive environments, but PEEK's mechanical strength is non-negotiable for ultra-high-pressure systems.

Making the Right Choice for Your Application

Analyze your system's specific demands to determine the most appropriate material.

- If your primary focus is extreme pressure and high temperature: PEEK is the most reliable choice due to its superior strength and thermal stability.

- If your primary focus is chemical compatibility and low friction: PTFE is unmatched for its chemical inertness and self-lubricating properties in dynamic seals.

- If your primary focus is a cost-effective solution for moderate conditions: Nylon provides a balanced and economical performance for general-purpose applications.

Ultimately, matching the material's specific strengths to your system's unique operating demands is the key to ensuring long-term seal integrity.

Summary Table:

| Material | Key Strengths | Ideal Use Cases |

|---|---|---|

| PTFE | Excellent chemical resistance, low friction, wide temp range (-200°C to 260°C) | Dynamic seals, corrosive environments, general-purpose applications |

| PEEK | Superior strength, high temp/pressure resistance, excellent creep resistance | Extreme pressure/temperature systems, demanding industrial applications |

| Nylon | Cost-effective, good mechanical strength for moderate conditions | General-purpose hydraulic/pneumatic systems, budget-conscious projects |

Need a custom backup ring solution? At KINTEK, we specialize in manufacturing precision PTFE components (including seals, liners, and labware) for the semiconductor, medical, laboratory, and industrial sectors. Whether you require prototypes or high-volume orders, our expertise ensures your backup rings meet exact pressure, temperature, and chemical compatibility demands. Contact us today to discuss your application and receive a tailored solution!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications