At its core, Polytetrafluoroethylene (PTFE) is a high-performance fluoropolymer best known for its extreme inertness and uniquely slick surface. Its defining characteristics are exceptional chemical resistance against nearly all substances, an incredibly low coefficient of friction that makes it one of the most slippery materials in existence, and remarkable stability across a wide temperature range.

PTFE, commonly known by the trade name Teflon®, is an elite problem-solving material for extreme environments. It excels where other materials fail due to chemical attack, high heat, or the need for a non-stick surface. However, this exceptional performance profile comes with the trade-off of relatively low mechanical strength, a critical factor in material selection.

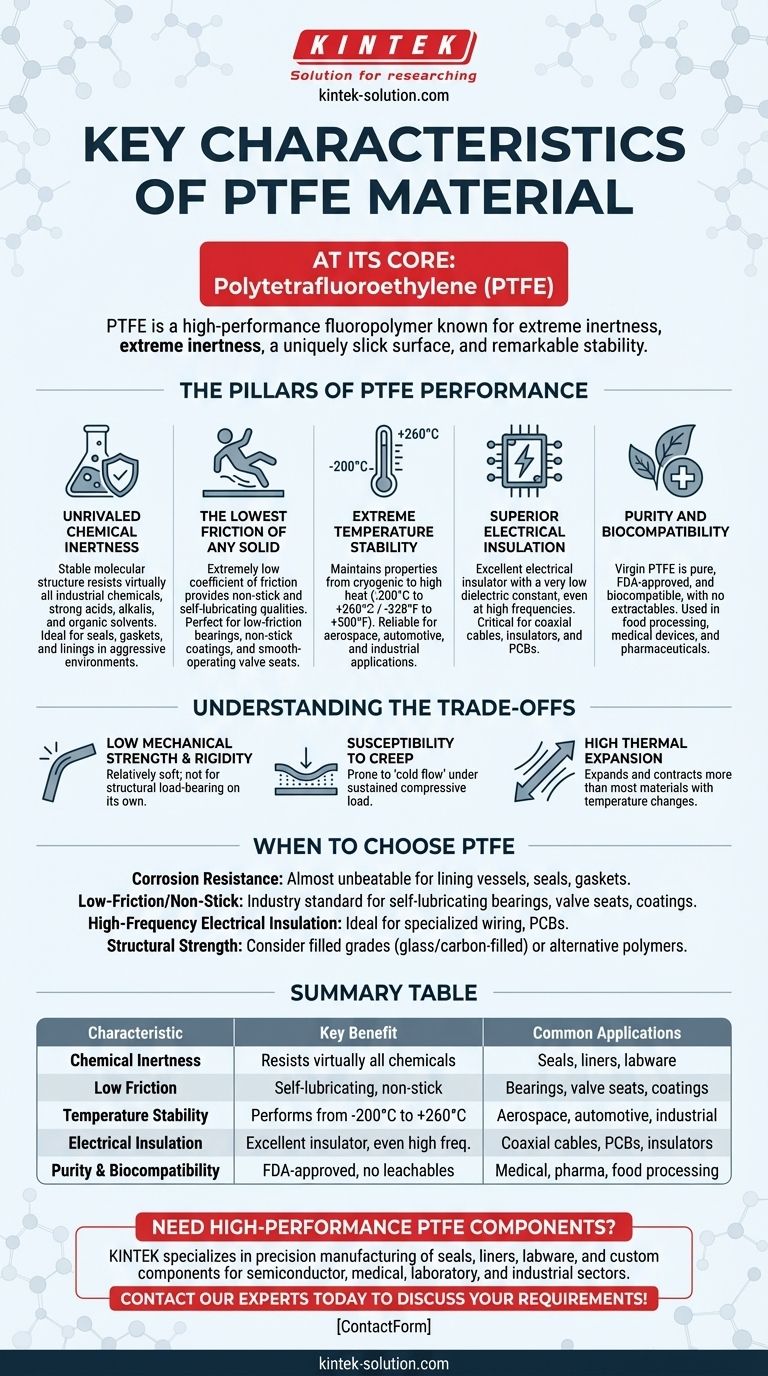

The Pillars of PTFE Performance

To understand if PTFE is the right choice for your application, you must look beyond a simple list of features and understand the practical implications of its core properties.

Unrivaled Chemical Inertness

PTFE's molecular structure is incredibly stable, making it resistant to virtually all industrial chemicals, including strong acids, alkalis, and organic solvents.

This near-universal resistance makes it a first-choice material for seals, gaskets, and linings in aggressive chemical processing, semiconductor manufacturing, and laboratory equipment.

The Lowest Friction of Any Solid

PTFE has one of the lowest coefficients of friction known for any solid material. This gives it its signature "non-stick" and self-lubricating qualities.

Because molecules have a difficult time adhering to its surface, PTFE is ideal for low-friction bearings, non-stick coatings on cookware, and components like valve seats that must operate smoothly without external lubrication.

Extreme Temperature Stability

PTFE maintains its properties across a vast thermal range, typically from -200°C to +260°C (-328°F to +500°F).

It does not become brittle at cryogenic temperatures or degrade in high heat, ensuring reliability in demanding aerospace, automotive, and industrial applications.

Superior Electrical Insulation

PTFE is an excellent electrical insulator with a very low dielectric constant, even at high frequencies.

This property is critical for manufacturing high-performance coaxial cables, insulators, and printed circuit boards (PCBs) used in microwave and radio-frequency applications.

Purity and Biocompatibility

Pure, or "virgin," PTFE is inherently pure and has virtually no extractables, meaning it does not leach chemicals into its environment.

This, combined with its biocompatibility, makes it FDA-approved for use in food processing equipment, medical devices, and pharmaceutical applications.

Understanding the Trade-offs

No material is perfect. While PTFE's strengths are significant, its limitations are equally important to consider for proper application design.

Low Mechanical Strength and Rigidity

Compared to other engineering plastics, PTFE is a relatively soft material. It has low tensile strength and is not suitable for structural, load-bearing components on its own.

Susceptibility to Creep

Under sustained compressive load, PTFE is prone to "creep," or cold flow, meaning it will slowly deform over time. This must be accounted for in the design of seals and gaskets.

High Thermal Expansion

PTFE has a high coefficient of thermal expansion, meaning it expands and contracts more than most materials with changes in temperature. This is a critical design consideration for parts requiring tight tolerances.

When to Choose PTFE

Your final decision should be based on your application's most critical requirement.

- If your primary focus is corrosion resistance: PTFE is an almost unbeatable choice for lining vessels, seals, and gaskets in aggressive chemical environments.

- If your primary focus is low-friction or non-stick surfaces: It is the industry standard for applications like self-lubricating bearings, valve seats, and high-performance coatings.

- If your primary focus is high-frequency electrical insulation: PTFE's low dielectric constant makes it ideal for specialized wiring and printed circuit boards.

- If your primary focus is structural strength: You should consider filled grades of PTFE (e.g., glass or carbon-filled) or look to alternative engineering polymers.

Understanding these core properties and their inherent trade-offs is the key to leveraging PTFE's unique capabilities effectively.

Summary Table:

| Characteristic | Key Benefit | Common Applications |

|---|---|---|

| Chemical Inertness | Resists virtually all chemicals | Seals, liners, labware for chemical processing |

| Low Friction | Self-lubricating, non-stick | Bearings, valve seats, non-stick coatings |

| Temperature Stability | Performs from -200°C to +260°C | Aerospace, automotive, industrial components |

| Electrical Insulation | Excellent insulator, even at high frequencies | Coaxial cables, PCBs, insulators |

| Purity & Biocompatibility | FDA-approved, no leachables | Medical devices, pharmaceutical, food processing |

Need high-performance PTFE components for your critical application?

At KINTEK, we specialize in precision manufacturing of PTFE seals, liners, labware, and custom components. Whether you require prototypes or high-volume orders for the semiconductor, medical, laboratory, or industrial sectors, our expertise ensures your parts meet the extreme demands of chemical resistance, temperature stability, and purity.

Contact our experts today to discuss your specific requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What is PTFE commonly known as and what type of material is it? A Guide to High-Performance PTFE Properties

- What are the similarities between PTFE and RPTFE? Unlocking the Core Fluoropolymer Identity

- What environmental resistances does PTFE offer? Unmatched Durability for Harsh Conditions

- How does PTFE react to common solvents? Discover Its Near-Total Chemical Immunity

- What is PTFE and what class of plastics does it belong to? A Guide to High-Performance Fluoropolymers