In demanding environments, PEEK is the superior choice over PTFE for applications that require high mechanical strength and dimensional stability when exposed to extreme heat, pressure, radiation, or steam. While PTFE is known for its chemical inertness and low friction, PEEK provides the structural integrity needed for load-bearing components in harsh conditions.

The decision between PEEK and PTFE is a classic engineering trade-off. You are choosing between PEEK's exceptional structural performance under stress and PTFE's unparalleled low-friction surface and chemical inertness.

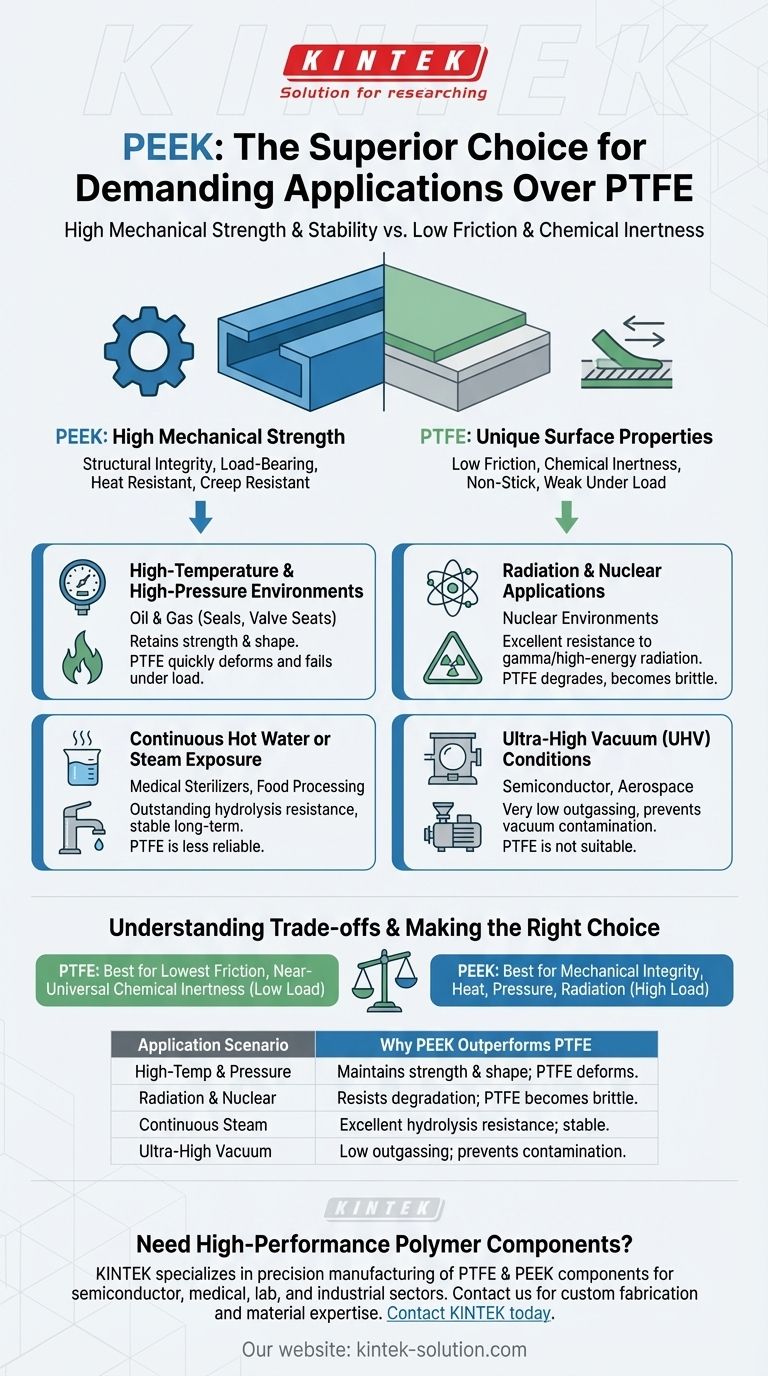

The Core Difference: Mechanical Strength vs. Surface Properties

The fundamental reason PEEK excels in certain applications comes down to its nature as a high-strength structural polymer, whereas PTFE is valued for its unique surface characteristics.

PEEK's Mechanical Advantage

PEEK (Polyether Ether Ketone) is a semi-crystalline thermoplastic known for its remarkable mechanical and thermal properties. It maintains high tensile strength, stiffness, and creep resistance even at elevated temperatures.

This means PEEK parts hold their shape and resist deformation under significant physical loads.

PTFE's Key Strengths

PTFE (Polytetrafluoroethylene) is a fluoropolymer prized for two main characteristics: its extremely low coefficient of friction (making it one of the "slipperiest" materials known) and its near-universal chemical inertness.

However, PTFE is mechanically weak. It is prone to "creep" or cold flow, meaning it will deform over time when subjected to a persistent load.

Key Scenarios Where PEEK is the Superior Choice

Based on these fundamental properties, PEEK clearly outperforms PTFE in several critical industrial applications.

High-Temperature and High-Pressure Environments

In the oil and gas industry, components like seals, valve seats, and compressor rings face extreme heat and pressure. PEEK’s ability to retain its strength and shape in these conditions prevents component failure.

PTFE, under the same high-pressure and high-temperature loads, would quickly deform and fail.

Radiation and Nuclear Applications

PEEK demonstrates excellent resistance to gamma and other high-energy radiation. Its molecular structure remains stable, ensuring components maintain their integrity within nuclear environments.

PTFE, by contrast, degrades when exposed to radiation, losing its mechanical properties and becoming brittle.

Continuous Hot Water or Steam Exposure

PEEK has outstanding hydrolysis resistance, meaning it does not break down or absorb significant moisture when exposed to continuous hot water or steam. This is critical for parts in medical sterilizers or food processing equipment.

This makes PEEK a reliable choice for long-term performance in wet, hot applications.

Ultra-High Vacuum (UHV) Conditions

In semiconductor manufacturing or aerospace applications, maintaining an ultra-high vacuum is essential. PEEK has very low outgassing properties, meaning it doesn't release trapped gases that would contaminate the vacuum.

This stability makes it a preferred material for components inside vacuum chambers.

Understanding the Trade-offs

Choosing PEEK is not always the right answer. Its advantages come with specific trade-offs that make PTFE the better choice in other contexts.

The Friction Factor

For applications where the lowest possible friction is the primary goal, PTFE is the undisputed champion. This includes non-stick coatings, low-friction bearings, and certain types of seals.

Chemical Inertness

While PEEK has broad chemical resistance, PTFE is inert to a wider range of aggressive chemicals. For liners and components in extreme chemical processing, PTFE is often the only viable option.

Cost and Processability

PEEK is a premium, high-cost material. It also requires very high processing temperatures, making it more difficult and expensive to manufacture into finished parts. PTFE is generally less expensive and easier to process.

Making the Right Choice for Your Application

To select the correct material, you must prioritize the most critical performance requirement for your component.

- If your primary focus is mechanical integrity under extreme heat, pressure, or radiation: PEEK is the clear and necessary choice for reliable, long-term performance.

- If your primary focus is the lowest possible friction or near-universal chemical resistance in a low-load scenario: PTFE is the more suitable and cost-effective material.

- If your primary focus is a general-purpose application without extreme environmental stressors: Both materials may be over-specified, and other engineering plastics should be considered.

Ultimately, aligning the unique strengths of the polymer with the specific demands of the application is the key to engineering success.

Summary Table:

| Application Scenario | Why PEEK Outperforms PTFE |

|---|---|

| High-Temperature & High-Pressure | Maintains strength & shape; PTFE deforms under load. |

| Radiation & Nuclear Environments | Resists degradation; PTFE becomes brittle. |

| Continuous Steam/Hot Water | Excellent hydrolysis resistance; stable long-term. |

| Ultra-High Vacuum (UHV) | Very low outgassing; prevents vacuum contamination. |

Need High-Performance Polymer Components?

Choosing between PEEK, PTFE, or other advanced polymers is critical for your application's success in harsh environments. KINTEK specializes in the precision manufacturing of PTFE components (seals, liners, labware) and other high-performance polymers for the semiconductor, medical, laboratory, and industrial sectors.

We provide custom fabrication from prototypes to high-volume orders, ensuring your components meet the exact demands for mechanical integrity, chemical resistance, and thermal stability.

Let our expertise guide your material selection and manufacturing. Contact KINTEK today to discuss your project requirements and receive a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What is the temperature range that PTFE can withstand? From -200°C to +260°C for Demanding Applications

- What are some applications of CNC machined PTFE parts? Critical Components for Medical, Electrical & Food Industries

- How is PTFE used in industrial processes? Maximize Safety and Efficiency

- What are some important physical property values for PTFE? Master Its Extreme Performance for Demanding Applications

- What is the hardness range of PTFE on the Shore D scale? Leveraging Its Softness for Superior Performance