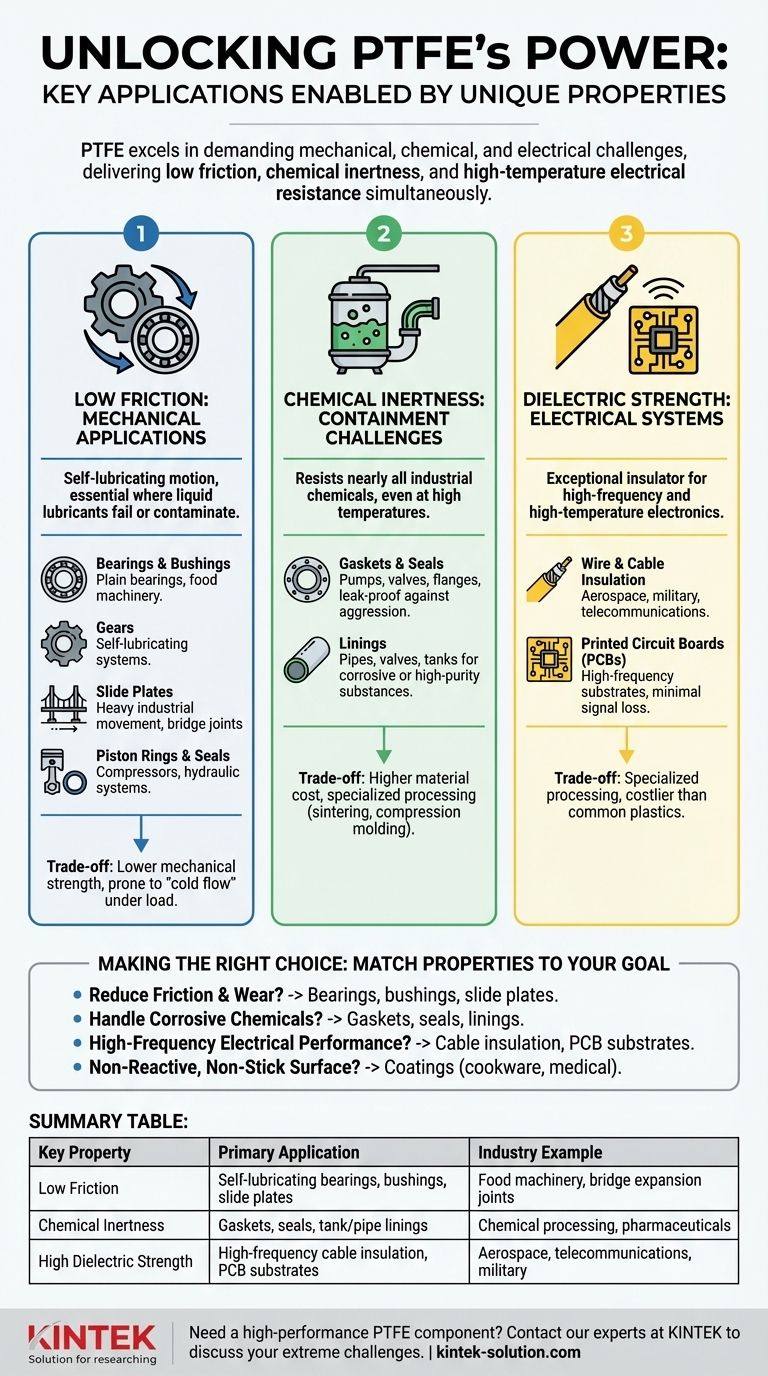

In short, PTFE is primarily used in demanding mechanical, chemical, and electrical applications where its unique combination of properties—low friction, chemical inertness, and high-temperature electrical resistance—solves problems that conventional materials cannot. This ranges from self-lubricating bearings in machinery and non-reactive linings for chemical tanks to high-performance insulation for critical wiring.

The core reason for PTFE's widespread use is not just one of its famous properties, but its ability to deliver several extreme performance characteristics simultaneously. Engineers choose PTFE when they need a material that can, for example, resist a highly corrosive chemical and a wide temperature range, or provide excellent electrical insulation and withstand harsh weather.

How Low Friction Drives Mechanical Applications

One of the most well-known properties of Polytetrafluoroethylene (PTFE) is its incredibly low coefficient of friction. This makes it a premier material for applications where smooth, low-wear movement is critical, often eliminating the need for liquid lubricants.

Bearings, Bushings, and Gears

PTFE is used to create plain bearings, bushings, and gears that are essentially self-lubricating.

This is invaluable in machinery where maintenance is difficult or where lubricants could contaminate the product, such as in the food and drink industry.

Slide Plates and Piston Rings

In heavy industrial and structural applications, slide plates made of PTFE allow for the slow, controlled movement of massive objects, like bridge sections or building foundations.

Its low friction also makes it ideal for piston rings and seals in compressors and hydraulic systems, ensuring efficient operation with minimal wear.

How Chemical Inertness Solves Containment Challenges

PTFE is almost completely inert, meaning it does not react with the vast majority of industrial chemicals, even at high temperatures. This makes it a fundamental material for the chemical processing industry.

Gaskets and Seals

The ability to withstand aggressive chemicals makes PTFE a top choice for gaskets and seals in pumps, valves, and flanges.

Furthermore, a property known as "creep" allows the material to slowly deform under pressure, enabling it to form a highly effective, leak-proof seal against container surfaces.

Linings for Pipes, Valves, and Tanks

To handle highly corrosive or high-purity substances, industrial pipes, valves, and vessels are often lined with a layer of PTFE.

This lining acts as a non-reactive barrier, protecting the structural metal from chemical attack and preventing contamination of the fluid being transported.

How Dielectric Strength Enables Electrical Systems

PTFE is an exceptional electrical insulator with a very high dielectric strength. It maintains these properties across a wide range of frequencies and temperatures, making it essential for high-performance electronics and wiring.

High-Performance Wire and Cable Insulation

PTFE is the preferred insulation for cables and wires used in critical aerospace, military, and telecommunications applications.

Its ability to insulate effectively at high frequencies and temperatures ensures signal integrity and reliability in the most demanding environments.

Printed Circuit Boards (PCBs)

For electronics that operate at very high frequencies, such as in radar and satellite communication systems, PTFE is used as the substrate material for circuit boards. Its low dielectric constant minimizes signal loss, ensuring superior performance.

Understanding the Trade-offs

While its properties are exceptional, PTFE is not a universal solution. Understanding its limitations is key to using it correctly.

Relatively Low Mechanical Strength

Compared to engineering plastics like nylon or PEEK, PTFE is quite soft and has lower tensile strength and wear resistance. It can deform under high loads, a phenomenon known as "cold flow" or creep.

Difficulty in Processing

PTFE cannot be processed using conventional melt techniques like injection molding. It must be formed using specialized and more costly methods like compression molding and sintering.

Higher Material Cost

As a high-performance fluoropolymer, PTFE is significantly more expensive than common plastics. Its use is typically reserved for applications where its unique capabilities are a strict requirement.

Making the Right Choice for Your Goal

Selecting PTFE is about matching its unique strengths to a specific, challenging problem that commodity materials cannot solve.

- If your primary focus is reducing friction and wear: PTFE is an excellent choice for self-lubricating bearings, bushings, and low-friction sliding surfaces.

- If your primary focus is handling corrosive chemicals: Use PTFE for gaskets, seals, and linings to ensure containment and prevent contamination.

- If your primary focus is high-frequency electrical performance: It is the material of choice for critical cable insulation and high-performance PCB substrates.

- If your primary focus is creating a non-reactive, non-stick surface: PTFE is ideal for coatings in cookware, medical devices, and industrial equipment.

Ultimately, PTFE is the engineer's choice for environments where reliability under extreme conditions is non-negotiable.

Summary Table:

| Key Property | Primary Application | Industry Example |

|---|---|---|

| Low Friction | Self-lubricating bearings, bushings, slide plates | Food machinery, bridge expansion joints |

| Chemical Inertness | Gaskets, seals, tank/pipe linings | Chemical processing, pharmaceuticals |

| High Dielectric Strength | High-frequency cable insulation, PCB substrates | Aerospace, telecommunications, military |

Need a high-performance PTFE component for your demanding application?

KINTEK specializes in manufacturing precision PTFE components—including seals, liners, labware, and custom fabrications—for the semiconductor, medical, laboratory, and industrial sectors. We deliver the material's unique properties with the exactitude your application requires, from prototypes to high-volume production.

Contact our experts today to discuss how our PTFE solutions can solve your extreme mechanical, chemical, or electrical challenges.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions