Polytetrafluoroethylene (PTFE) offers a unique combination of properties that make it the superior choice in specific, demanding environments. Its primary advantages over other engineering plastics like Nylon, PEEK, or Polycarbonate are its near-total chemical inertness, an exceptionally wide operating temperature range, and the lowest coefficient of friction of any solid material.

While other plastics may offer greater mechanical strength, PTFE is the definitive material for applications where extreme chemical exposure, high temperatures, and non-stick, low-friction performance are the most critical design requirements.

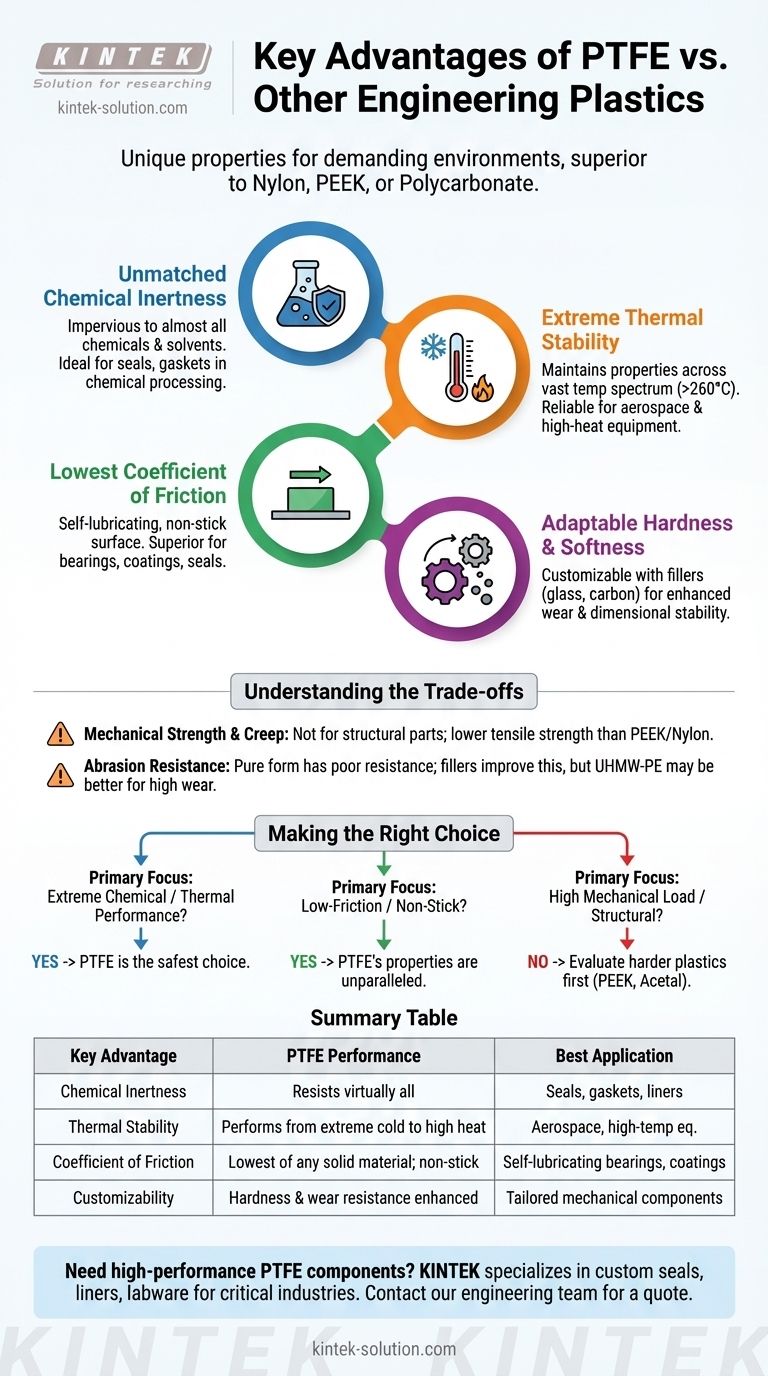

The Defining Properties of PTFE

To understand why PTFE is chosen for critical applications, we must analyze its core characteristics. These properties, when taken together, create a material profile that other plastics cannot match.

Unmatched Chemical Inertness

PTFE is virtually impervious to almost all industrial chemicals, solvents, and corrosive agents. This level of resistance is a significant advantage over high-performance plastics like PEEK and Nylon, which can degrade when exposed to certain aggressive substances.

This makes PTFE indispensable for seals, gaskets, and linings in chemical processing, where material failure is not an option.

Extreme Thermal Stability

The material maintains its properties across a vast temperature spectrum, performing reliably in extreme heat and cold where many other plastics would become brittle or melt.

This thermal stability ensures consistent performance in applications ranging from aerospace components to high-temperature industrial equipment.

The Lowest Coefficient of Friction

PTFE has an exceptionally low coefficient of friction, meaning other substances will not readily stick to it. This "non-stick" quality is superior to that of plastics like Acetal or Polycarbonate.

This property is fundamental to its use in self-lubricating bearings, non-stick coatings, and seals where minimizing resistance and preventing material buildup is essential.

Adaptable Hardness and Softness

While inherently a relatively soft material, PTFE's properties can be customized. The addition of fillers like glass, carbon, or bronze can enhance its hardness, wear resistance, and dimensional stability.

This adaptability allows engineers to tailor PTFE to meet the specific mechanical demands of an application without sacrificing its core benefits.

Understanding the Trade-offs

No material is perfect for every situation. Being an objective advisor means acknowledging where PTFE has limitations compared to other engineering plastics.

Mechanical Strength and Creep

PTFE is not a structural plastic. It has lower tensile strength and is more susceptible to "creep" (deformation under sustained load) than materials like PEEK, Nylon, or Acetal.

For high-load mechanical parts that require structural rigidity and impact resistance, other engineering plastics are often the more appropriate choice.

Abrasion Resistance

In its pure form, PTFE has relatively poor abrasion resistance. While fillers can significantly improve this, plastics like Nylon or UHMW-PE are inherently better suited for high-wear applications involving friction with abrasive materials.

Making the Right Choice for Your Application

Selecting the correct material requires a clear understanding of your primary design goal. Use these guidelines to determine if PTFE is the optimal solution.

- If your primary focus is performance in extreme chemical or thermal environments: PTFE is almost always the correct and safest choice.

- If your primary focus is creating a low-friction or non-stick surface: PTFE's properties are unparalleled for applications like sliding bearings, gaskets, and seals.

- If your primary focus is high mechanical load or structural integrity: You should evaluate harder, stronger plastics like PEEK, Acetal, or Nylon first.

By understanding these core strengths and trade-offs, you can confidently specify PTFE for the demanding applications where it truly excels.

Summary Table:

| Key Advantage | PTFE Performance | Best Application |

|---|---|---|

| Chemical Inertness | Resists virtually all industrial chemicals & solvents | Seals, gaskets, liners in chemical processing |

| Thermal Stability | Performs from extreme cold to high heat (>260°C) | Aerospace components, high-temperature equipment |

| Coefficient of Friction | Lowest of any solid material; non-stick | Self-lubricating bearings, non-stick coatings |

| Customizability | Hardness & wear resistance enhanced with fillers | Tailored components for specific mechanical needs |

Need high-performance PTFE components for your critical application?

At KINTEK, we specialize in the precision manufacturing of custom PTFE seals, liners, labware, and more for the semiconductor, medical, laboratory, and industrial sectors. Whether you require prototypes or high-volume orders, our expertise ensures you get components that deliver superior chemical resistance, thermal stability, and non-stick performance.

Contact our engineering team today to discuss your project requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments