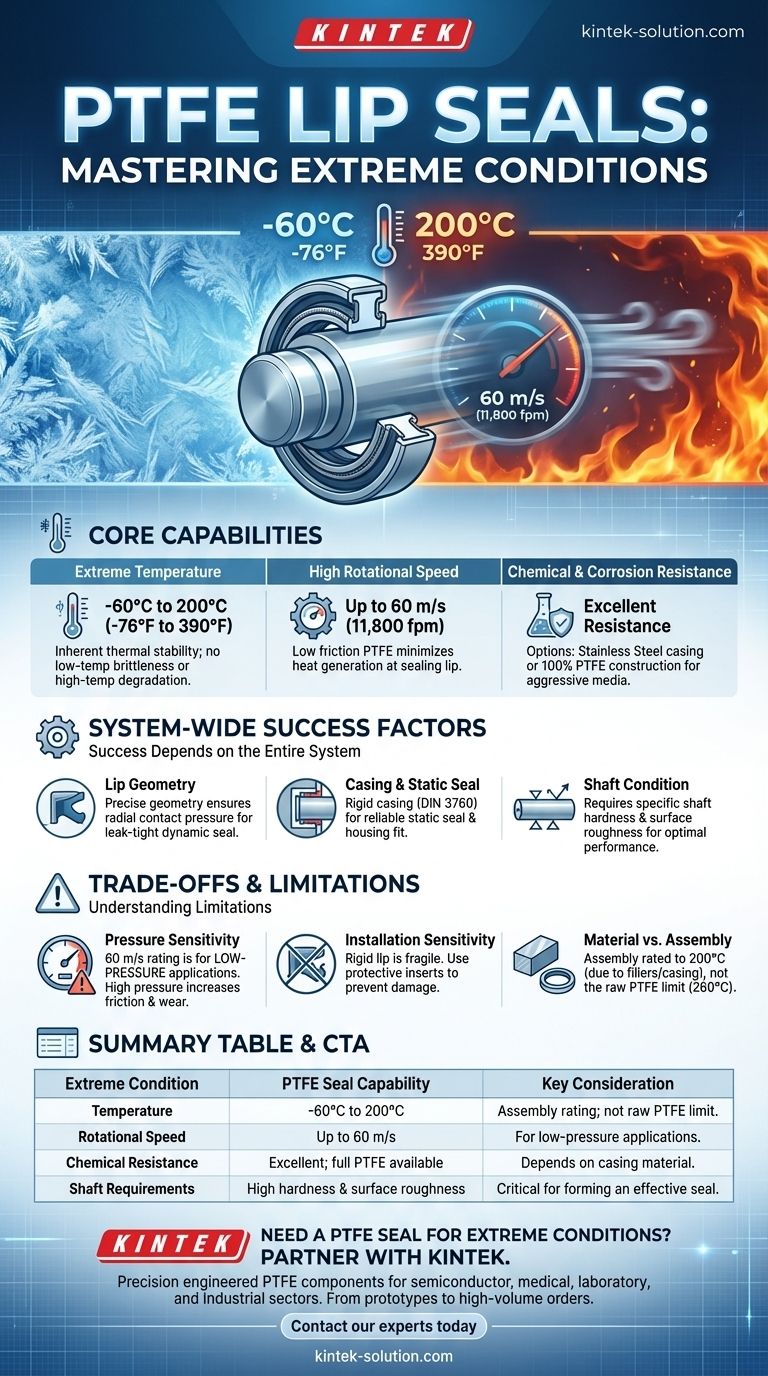

To be clear, standard PTFE lip seals are engineered to operate within a temperature range of -60°C to 200°C (-76°F to 390°F). In low-pressure environments, they can handle exceptionally high shaft speeds up to 60 m/s (11,800 fpm), making them suitable for demanding rotational applications.

While PTFE's material properties provide a remarkable tolerance for temperature and speed, a seal's true performance in extreme conditions depends on the entire system—from its mechanical design and material composition to the properties of the shaft it seals against.

Deconstructing the Core Capabilities

To understand if a PTFE lip seal is the correct solution, we must look beyond the headline numbers and analyze the factors that enable this performance.

Extreme Temperature Range

The operational temperature range of -60°C to 200°C is a direct result of Polytetrafluoroethylene's (PTFE) inherent thermal stability. Unlike many elastomers, it does not become brittle at low temperatures or degrade rapidly at high temperatures within this window.

High Rotational Speed

The ability to handle shaft speeds of 60 m/s is due to PTFE's extremely low coefficient of friction. This property minimizes heat generation at the sealing lip, preventing premature wear and failure that would occur with other materials at such high velocities.

Chemical and Corrosion Resistance

For applications involving aggressive media, the material composition is critical. While standard seals use a mild steel casing, options for stainless steel or even 100% PTFE construction (no steel casing) are available for maximum corrosion resistance.

Why the Entire System Dictates Success

A seal's specifications on paper are only realized when the entire mechanical system is optimized. The performance of a PTFE lip seal is not just about the PTFE material itself.

The Importance of Lip Geometry

The precise geometry of the sealing lip is engineered to exert a specific radial contact pressure on the shaft. This carefully controlled force is what ensures a leak-tight dynamic seal without causing excessive friction or wear.

The Casing and Static Seal

The outer steel casing provides structural rigidity and ensures a precise interference fit in the seal housing, often adhering to standards like DIN 3760. This creates a reliable static seal, preventing leaks around the outside of the seal body itself.

The Shaft's Critical Influence

The condition of the shaft is arguably one of the most critical factors. PTFE seals function differently than traditional elastomeric seals. They require a specific shaft hardness and surface roughness to create a proper seal, making shaft preparation a crucial step for optimal life and performance.

Understanding the Trade-offs and Limitations

Objectivity requires acknowledging where these seals may not be the ideal choice or what precautions are necessary for success.

Pressure Sensitivity at High Speeds

The impressive 60 m/s speed rating is explicitly for low-pressure applications. As pressure increases, the forces on the sealing lip also increase, which can lead to higher friction, heat, and accelerated wear, especially when combined with high speeds.

Installation Sensitivity

The PTFE sealing lip is rigid and can be easily damaged during installation. A small nick or scratch on the lip will compromise the seal immediately. Using protective plastic or cardboard inserts during installation is not just a recommendation; it is essential.

Material Potential vs. Assembly Limits

It is important not to confuse the properties of raw PTFE with the rating of a complete seal assembly. While pure PTFE bushings can withstand temperatures up to 260°C, the PTFE lip seal assembly is rated to 200°C. This limit is dictated by the complete construction, including fillers in the PTFE compound and the metal casing.

Making the Right Choice for Your Application

To ensure reliability, your selection must be based on the primary challenge of your operating environment.

- If your primary focus is high speed: Prioritize managing system pressure and ensuring the shaft has the optimal surface hardness and finish.

- If your primary focus is extreme temperature: Confirm your application falls within the -60°C to 200°C range and account for the thermal expansion of all housing and shaft components.

- If your primary focus is chemical resistance: Specify a seal with a stainless steel casing or, for the most aggressive environments, a 100% PTFE seal to eliminate casing corrosion.

Ultimately, selecting the right PTFE lip seal is about matching the total system's capabilities to your specific operational demands.

Summary Table:

| Extreme Condition | PTFE Lip Seal Capability | Key Consideration |

|---|---|---|

| Temperature | -60°C to 200°C (-76°F to 390°F) | Assembly rating; not raw PTFE limit. |

| Rotational Speed | Up to 60 m/s (11,800 fpm) | For low-pressure applications. |

| Chemical Resistance | Excellent; full PTFE construction available | Depends on casing material (steel, stainless, 100% PTFE). |

| Shaft Requirements | High hardness & specific surface roughness | Critical for forming an effective seal. |

Need a PTFE Seal for Extreme Conditions? Partner with KINTEK.

Your demanding application requires a seal that is precisely engineered for its environment. KINTEK specializes in manufacturing high-performance PTFE components, including custom lip seals, for the semiconductor, medical, laboratory, and industrial sectors. We ensure precision production and offer custom fabrication from prototypes to high-volume orders to meet your exact specifications.

Contact our experts today to discuss how our PTFE lip seals can solve your most challenging sealing problems.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance