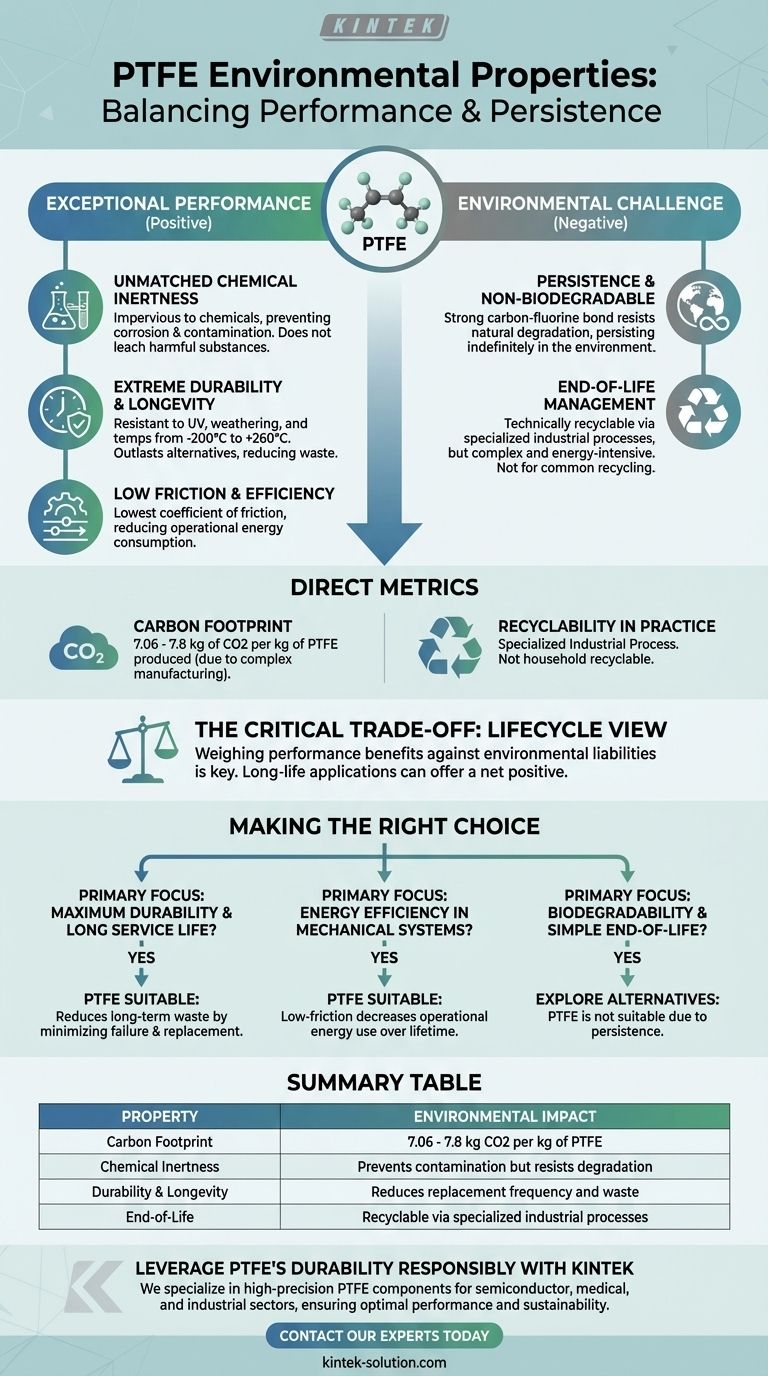

From a direct data perspective, the environmental footprint of Polytetrafluoroethylene (PTFE) is 7.06 to 7.8 kg of CO2 per kg of material produced. While PTFE is technically recyclable, its full environmental story is far more complex, directly tied to the same chemical properties that make it so uniquely high-performing.

The core environmental characteristic of PTFE is a duality: its exceptional chemical inertness and durability create long-lasting, efficient products, but this same resistance to degradation means it persists indefinitely in the environment if not managed correctly.

The Link Between Performance and Environmental Impact

The properties that define PTFE as a premier engineering material are the very same properties that define its environmental profile. Understanding this connection is key to making an informed decision.

Unmatched Chemical Inertness

PTFE is virtually impervious to chemical attack and is stable against almost all industrial chemicals, acids, and solvents.

This inertness is a major advantage in applications like seals and vessel linings, preventing corrosion and contamination. Environmentally, this means the material does not break down or leach harmful substances during its service life.

However, this same property means PTFE does not biodegrade. If it enters the environment, it persists.

Extreme Durability and Longevity

The material has outstanding resistance to weathering, UV light, and extreme temperatures, operating effectively from -200°C to +260°C.

This resilience translates to a remarkably long service life. A component made from PTFE will often outlast alternatives many times over, reducing the need for replacements and lowering the total material consumption over the life of an assembly.

Low Friction and Efficiency

PTFE possesses the lowest coefficient of friction of any known solid material, making it incredibly slippery.

In mechanical applications, this non-stick, low-friction surface reduces the energy required to overcome resistance. This can lead to significant energy savings and improved operational efficiency, an indirect but important environmental benefit.

Understanding the Direct Metrics

Beyond its inherent properties, we can look at the specific data associated with PTFE's lifecycle.

Carbon Footprint

The production of 1 kg of PTFE generates between 7.06 and 7.8 kg of CO2.

This figure represents the emissions associated with the complex manufacturing process required to create such a stable and high-performance polymer.

Recyclability in Practice

While PTFE is recyclable, this process is not the same as common household plastic recycling.

It involves a specialized industrial process where scrap and used material are ground down and reprocessed, often into less-demanding applications. This keeps the material out of landfills and extends its useful life, but it remains a specialized, energy-intensive procedure.

The Critical Trade-offs

Using PTFE requires a clear understanding of its benefits and environmental liabilities. Its selection must be a conscious choice based on the application's demands.

The Challenge of Persistence

The single greatest environmental drawback of PTFE is its persistence. The strong carbon-fluorine bond that makes it so stable and inert also makes it resistant to natural degradation processes.

This means that proper end-of-life management, such as industrial recycling or containment, is essential to prevent its accumulation in the environment.

The Importance of the Lifecycle View

The environmental cost of PTFE is best evaluated over the entire product lifecycle.

Using an energy-intensive, persistent material for a disposable, low-value application is difficult to justify. However, using it for a critical, long-life component that enhances safety, prevents chemical leaks, or improves energy efficiency can present a net environmental positive.

Making the Right Choice for Your Goal

To determine if PTFE is appropriate, you must weigh its unparalleled performance against its environmental persistence.

- If your primary focus is maximum durability and long service life: PTFE's resistance to chemicals and weathering can reduce long-term waste by minimizing component failure and replacement.

- If your primary focus is energy efficiency in a mechanical system: PTFE's low-friction properties can decrease operational energy consumption over the product's lifetime.

- If your primary focus is biodegradability and simple end-of-life processing: PTFE is not a suitable choice, and you should explore alternative materials.

Ultimately, the environmental responsibility of using PTFE is determined by whether its unique durability is leveraged to solve a problem that no other material can address as effectively.

Summary Table:

| Property | Environmental Impact |

|---|---|

| Carbon Footprint | 7.06 - 7.8 kg CO2 per kg of PTFE |

| Chemical Inertness | Prevents contamination but resists degradation |

| Durability & Longevity | Reduces replacement frequency and waste |

| End-of-Life | Recyclable via specialized industrial processes |

Leverage PTFE's Durability Responsibly

Choosing the right material is a critical balance between performance and environmental impact. At KINTEK, we specialize in manufacturing high-precision PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, and industrial sectors.

We help you maximize PTFE's benefits, such as its long service life and energy-efficient low-friction properties, to ensure your application achieves a net positive outcome. Whether you need prototypes or high-volume orders, our custom fabrication expertise ensures optimal performance and sustainability.

Ready to find the right material solution for your project? Contact our experts today for a consultation.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- How do additives enhance the properties of PTFE for demanding applications? Unlock High-Performance PTFE Solutions

- Why is Teflon suitable for waterproof makeup products? Unlock the Secret to Smudge-Proof Wear

- What industries commonly use Teflon material? Unlocking Versatility Across Sectors

- What is the maximum service temperature for PTFE? A Guide to Safe & Reliable Use

- How does PTFE perform in high-temperature and dirty environments? Discover its Resilience and Reliability

- What properties make Teflon ideal for medical applications? Discover Its Critical Role in Safety & Performance

- How is PTFE produced? From TFE Gas to High-Performance Polymer

- What are the uses of PTFE in the automotive industry? Ensuring Reliability in Extreme Conditions