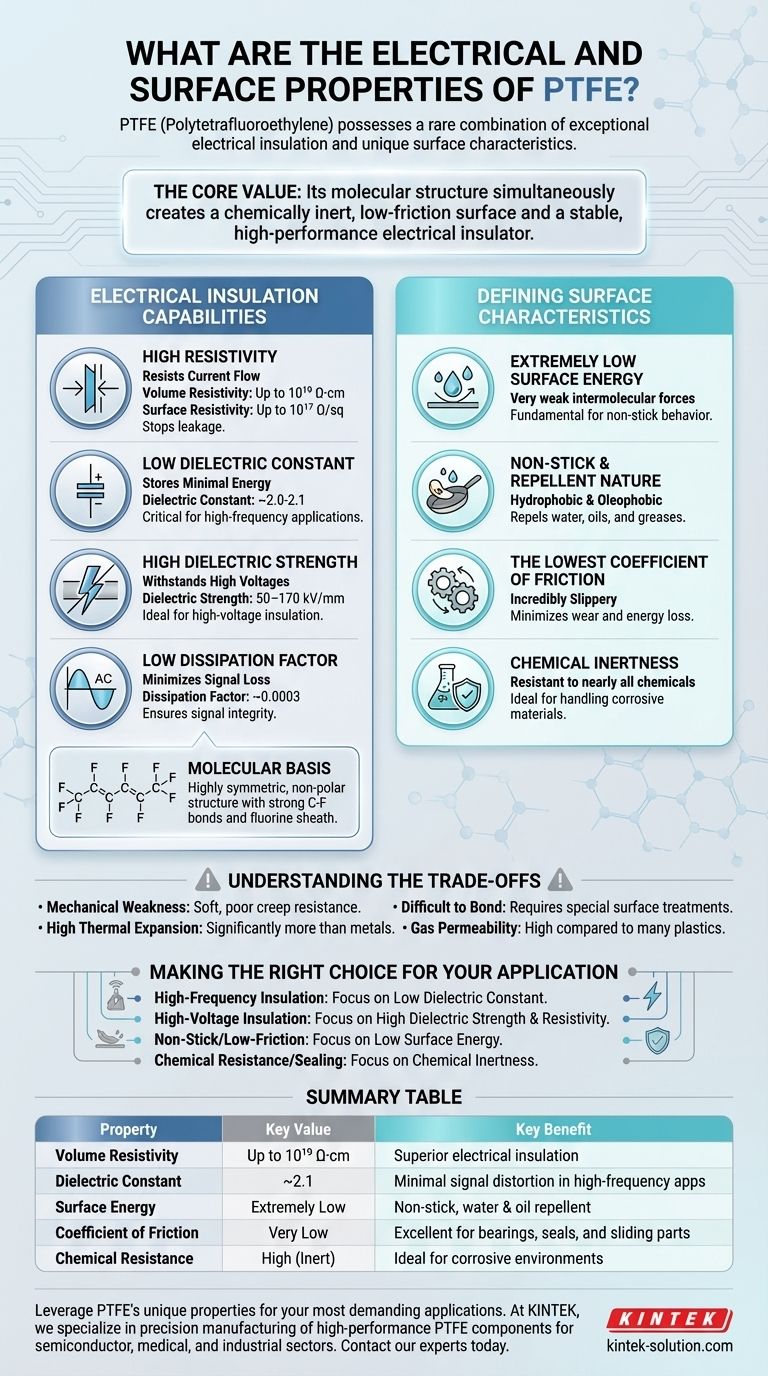

At its core, Polytetrafluoroethylene (PTFE) possesses a rare combination of exceptional electrical insulation and unique surface characteristics. Its electrical properties include an extremely high volume resistivity of up to 10¹⁹ Ω·cm and a very low dielectric constant of 2.1, making it one of the best insulators available. On the surface, its low surface energy results in the famous non-stick, water-repellent, and low-friction behavior it is known for.

The true value of PTFE lies in its molecular structure, which simultaneously creates a chemically inert, low-friction surface and a stable, high-performance electrical insulator. Understanding how these distinct property sets interact is key to leveraging this material for demanding applications.

Unpacking PTFE's Electrical Insulation Capabilities

PTFE's reputation as a premier electrical insulator stems from a set of elite, quantifiable properties. These characteristics are remarkably stable across wide temperature and frequency ranges.

High Resistivity: Resisting Current Flow

PTFE is an expert at preventing the flow of electricity where it isn't wanted. Its surface resistivity (up to 10¹⁷ Ω/sq) and volume resistivity (up to 10¹⁹ Ω·cm) are exceptionally high, effectively stopping current leakage along its surface or through its bulk.

Low Dielectric Constant: Storing Minimal Energy

With a dielectric constant of just 2.0-2.1, PTFE stores very little electrical energy when subjected to an electric field. This is critical for high-frequency applications, like coaxial cables and printed circuit boards, as it minimizes signal distortion and capacitance issues.

High Dielectric Strength: Withstanding High Voltages

PTFE demonstrates a robust dielectric strength ranging from 50 to 170 kV/mm. This means it can withstand a very high voltage across a small thickness before breaking down, making it an ideal insulator for high-voltage wiring and components.

Low Dissipation Factor: Minimizing Signal Loss

The material's very low dissipation factor (around 0.0003) signifies that minimal energy is lost as heat when an alternating current is applied. This ensures signal integrity and high efficiency in AC circuits.

The Molecular Basis for Excellence

These superior electrical properties are a direct result of PTFE's highly symmetric molecular structure. The strong carbon-fluorine bonds and the uniform sheath of fluorine atoms around the carbon backbone create a non-polar material that does not easily interact with electric fields.

The Defining Surface Characteristics of PTFE

PTFE's surface behavior is as remarkable as its electrical performance. These properties all derive from one fundamental characteristic: extremely low surface energy.

Extremely Low Surface Energy

PTFE's surface has very weak intermolecular forces. This means that other substances have little to no attraction to it, which is the foundational reason for its "non-stick" nature.

Non-Stick and Repellent Nature

Because nothing wants to stick to it, PTFE is both hydrophobic (repels water) and oleophobic (repels oils and greases). This makes it invaluable for cookware, stain-resistant fabrics, and industrial molds.

The Lowest Coefficient of Friction

PTFE has one of the lowest coefficients of friction of any known solid. This makes it incredibly slippery, ideal for use in low-friction bearings, seals, and other sliding applications where minimizing wear and energy loss is critical.

Chemical Inertness

The same strong carbon-fluorine bonds that provide electrical stability also make PTFE's surface almost completely inert. It is resistant to nearly all chemicals and solvents, making it a first choice for handling corrosive materials.

Understanding the Trade-offs

While its properties are exceptional, PTFE is not a universal solution. An expert advisor must acknowledge its practical limitations.

Mechanical Weakness

PTFE is a relatively soft material. It has poor resistance to creep (deformation under sustained load) and is not suitable for high-load structural applications without reinforcement (e.g., glass-filled PTFE).

Difficult to Bond

The very non-stick properties that make PTFE so useful also make it extremely difficult to bond to other materials. Special surface treatments like chemical etching are required to achieve any meaningful adhesion.

High Thermal Expansion

PTFE has a high coefficient of thermal expansion compared to metals. This can cause issues in assemblies that experience significant temperature fluctuations, as the PTFE component will expand and contract much more than its metal counterparts.

Gas Permeability

Unlike many plastics, PTFE has a high gas permeability, similar to silicones. While this can be an advantage in some breathable membrane applications, it is a significant drawback where a vacuum or gas-tight barrier is required.

Making the Right Choice for Your Application

Selecting PTFE is about matching its unique strengths to a specific engineering challenge. Your primary goal will determine which of its properties is most valuable.

- If your primary focus is high-frequency electrical insulation: PTFE's extremely low and stable dielectric constant is its most valuable asset for preserving signal integrity.

- If your primary focus is high-voltage insulation: Its high dielectric strength and massive volume resistivity ensure it can prevent electrical breakdown and current leakage.

- If your primary focus is creating a non-stick, low-friction surface: PTFE's low surface energy is the key property, delivering unmatched slipperiness and release characteristics.

- If your primary focus is chemical resistance and sealing: Its near-total chemical inertness makes it the definitive choice for gaskets, seals, and linings in corrosive environments.

Ultimately, PTFE is a high-performance material whose value is realized when its distinct properties are precisely matched to a demanding application.

Summary Table:

| Property | Key Value | Key Benefit |

|---|---|---|

| Volume Resistivity | Up to 10¹⁹ Ω·cm | Superior electrical insulation |

| Dielectric Constant | ~2.1 | Minimal signal distortion in high-frequency apps |

| Surface Energy | Extremely Low | Non-stick, water & oil repellent |

| Coefficient of Friction | Very Low | Excellent for bearings, seals, and sliding parts |

| Chemical Resistance | High (Inert) | Ideal for corrosive environments |

Leverage PTFE's unique properties for your most demanding applications.

At KINTEK, we specialize in the precision manufacturing of high-performance PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your parts deliver unmatched electrical insulation, chemical resistance, and non-stick performance.

Whether you need prototypes or high-volume production, we provide custom fabrication to meet your exact specifications.

Contact our experts today to discuss how our PTFE solutions can solve your specific engineering challenges.

Visual Guide

Related Products

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What is PTFE and what class of plastics does it belong to? A Guide to High-Performance Fluoropolymers

- What environmental resistances does PTFE offer? Unmatched Durability for Harsh Conditions

- What is Teflon and what is its chemical name? Unpacking the Science of PTFE

- How was PTFE discovered and developed? From Lab Accident to Essential High-Performance Polymer

- How does PTFE's molecular structure contribute to its non-stick properties? The Science Behind Its Slick Surface