The durability of Polytetrafluoroethylene (PTFE) is exceptional, stemming from a powerful combination of chemical inertness, thermal stability, and robust physical properties. It is highly resistant to weathering, including UV light, oxidation, and embrittlement, and does not degrade or discolor when exposed to the elements. This resilience, combined with a high melting point and excellent wear resistance, makes it a premier material for long-term performance in demanding environments.

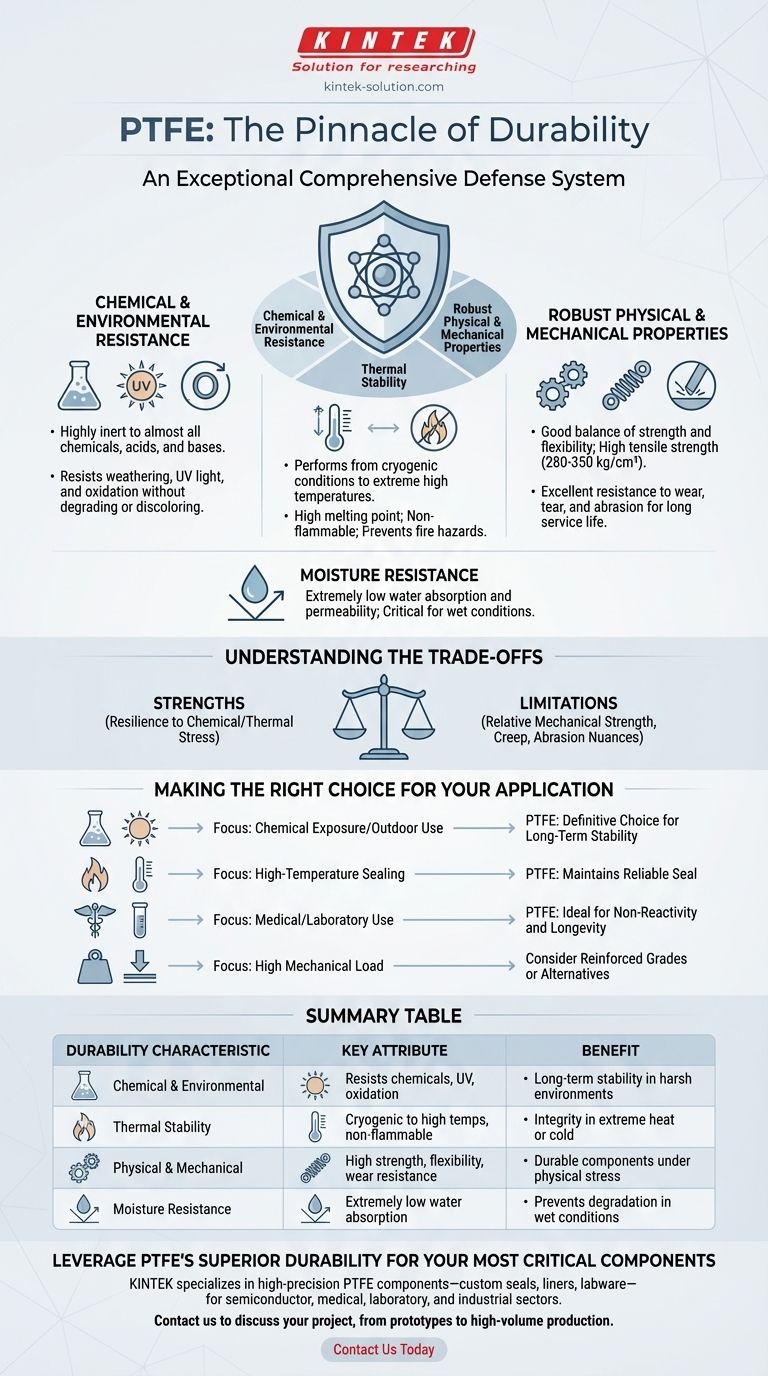

PTFE's durability is not a single characteristic but a comprehensive defense system. Its core strength lies in its extreme stability against chemical attack, temperature fluctuations, and environmental exposure, ensuring reliable and long-lasting integrity in applications where other materials would fail.

The Pillars of PTFE's Durability

To understand why PTFE is so reliable, we must examine the specific properties that contribute to its resilience. These characteristics work in concert to protect it from nearly all forms of degradation.

Unmatched Chemical and Environmental Resistance

PTFE is one of the most chemically inert polymers known. This means it is highly resistant to corrosion and attack from almost all chemicals, acids, and bases.

This inertness is paired with outstanding resistance to weathering. PTFE withstands long-term exposure to UV radiation and oxidation without becoming brittle or discolored, a common failure point for many other plastics in outdoor applications.

Exceptional Thermal Stability

The material demonstrates impressive performance across a wide range of temperatures. It maintains its structural integrity in both cryogenic conditions and high-heat environments.

Furthermore, PTFE has a very high melting point and is non-flammable. This thermal stability prevents it from degrading, melting, or becoming a fire hazard in applications involving extreme heat.

Robust Physical and Mechanical Properties

PTFE exhibits a good balance of strength and flexibility. It has a high tensile strength, measuring between 280-350 kg/cm², and a high degree of elongation (200-400%), allowing it to deform without breaking.

This toughness translates to excellent resistance to wear, tear, and abrasion, ensuring a long service life for components like seals, liners, and fittings that experience physical stress.

Impermeability and Moisture Resistance

PTFE has extremely low water absorption and permeability. It effectively repels moisture, which is critical for preventing degradation and maintaining performance in wet or humid conditions.

This property is vital for applications like electrical plugs, medical liners, and O-rings, where moisture intrusion could lead to failure.

Understanding the Trade-offs

While PTFE's durability is remarkable, no material is without limitations. Objectivity requires acknowledging where its properties fit within the broader engineering landscape.

Relative Mechanical Strength

PTFE is tough and flexible, but it is not as rigid or strong as metals or some high-performance engineering plastics. Its primary advantage is its resilience under chemical and thermal stress, not its ability to bear extreme mechanical loads.

Susceptibility to Creep

Under a sustained compressive load, PTFE can slowly deform over time, a phenomenon known as "creep" or "cold flow." This characteristic must be accounted for in the design of high-pressure seals or structural components to ensure long-term integrity.

Abrasion Resistance Nuances

While PTFE has good wear resistance, especially in low-friction applications, it can be susceptible to abrasion from hard, sharp particles. For highly abrasive environments, filled grades of PTFE (mixed with materials like glass fiber or carbon) are often specified to enhance this property.

Making the Right Choice for Your Application

Selecting a material depends entirely on the primary challenges of your project. PTFE is an elite performer, but only when its strengths are aligned with the application's demands.

- If your primary focus is chemical exposure or outdoor use: PTFE's unparalleled inertness and resistance to UV radiation make it the definitive choice for long-term stability.

- If your primary focus is high-temperature sealing: Its thermal stability and low compression set ensure it maintains a reliable seal in environments that would degrade other elastomers.

- If your primary focus is medical or laboratory use: Its chemical purity, low water absorption, and resistance to wear make it ideal for liners, vials, and tubing that require non-reactivity and longevity.

- If your primary focus is high mechanical load: Carefully evaluate the potential for creep under sustained pressure and consider reinforced grades or alternative materials if rigidity is the dominant requirement.

Ultimately, understanding PTFE's specific durability profile allows you to leverage its unique strengths for unparalleled performance in the most challenging conditions.

Summary Table:

| Durability Characteristic | Key Attribute | Benefit |

|---|---|---|

| Chemical & Environmental | Resists almost all chemicals, acids, bases, UV light, and oxidation. | Long-term stability in harsh or outdoor environments. |

| Thermal Stability | Performs from cryogenic to high temperatures (high melting point, non-flammable). | Maintains integrity in extreme heat or cold. |

| Physical & Mechanical | High tensile strength, flexibility, and excellent wear/abrasion resistance. | Durable seals, liners, and components under physical stress. |

| Moisture Resistance | Extremely low water absorption and permeability. | Prevents degradation in wet or humid conditions. |

Leverage PTFE's superior durability for your most critical components.

At KINTEK, we specialize in manufacturing high-precision PTFE components—from custom seals and liners to labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your parts are engineered to withstand the specific chemical, thermal, and mechanical challenges of your application, maximizing longevity and performance.

Contact us today to discuss your project requirements, from prototypes to high-volume production, and discover how our precision PTFE solutions can enhance your product's reliability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments