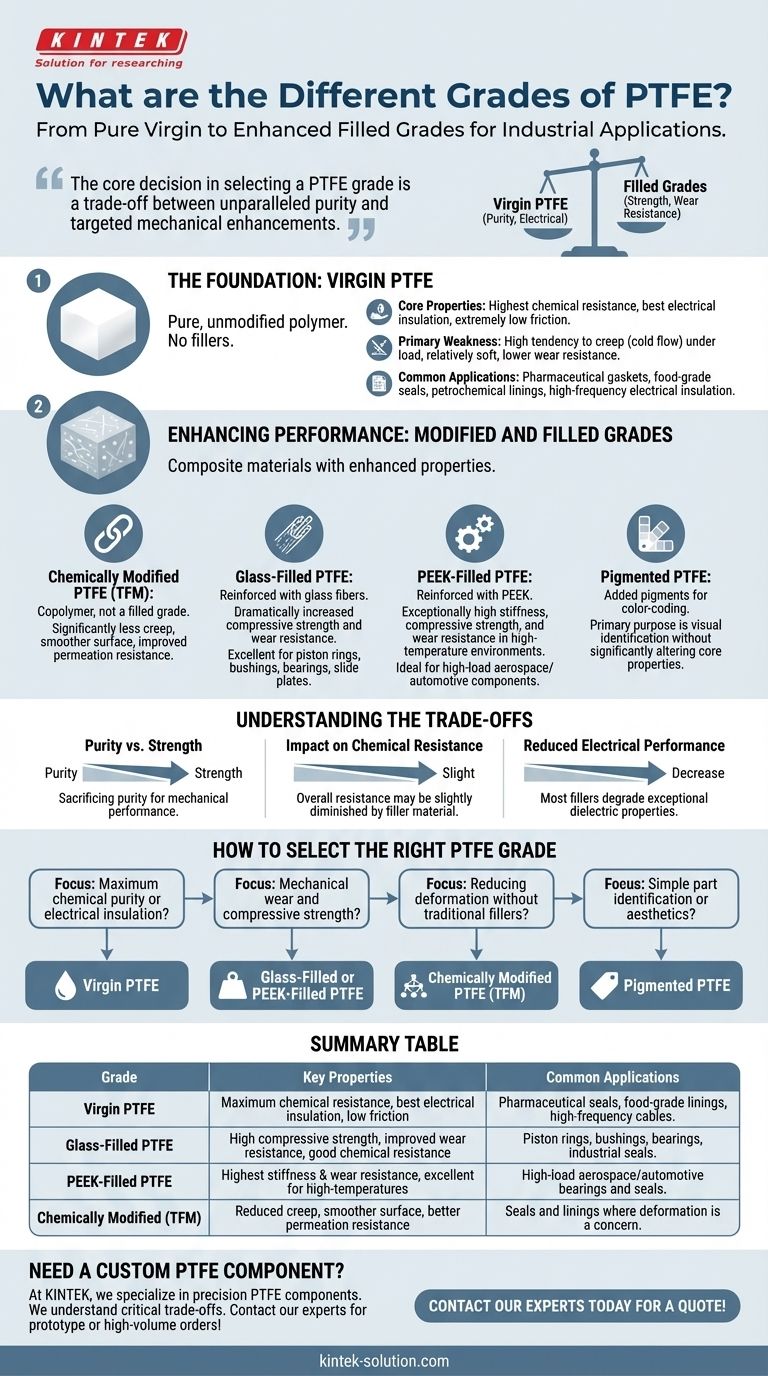

In short, the primary grades of Polytetrafluoroethylene (PTFE) are Virgin PTFE and various "filled" grades. Virgin PTFE is the pure, unmodified polymer prized for its exceptional chemical resistance and electrical insulation. Filled grades, such as glass-filled or PEEK-filled, add other materials to the PTFE matrix to enhance specific mechanical properties like compressive strength and wear resistance for more demanding physical applications.

The core decision in selecting a PTFE grade is a trade-off. You must balance the unparalleled chemical and electrical purity of Virgin PTFE against the targeted mechanical enhancements—like improved strength and reduced creep—offered by modified and filled grades.

The Foundation: Virgin PTFE

Virgin PTFE is the starting point from which all other grades are derived. It is pure, unadulterated Polytetrafluoroethylene without any fillers.

Core Properties

This grade exhibits the fundamental properties that make PTFE so valuable. It has the highest chemical resistance, the best electrical insulation capabilities, and an extremely low coefficient of friction.

Its Primary Weakness

The main limitation of Virgin PTFE is its tendency to deform under load, a phenomenon known as creep or cold flow. It is also relatively soft, leading to lower wear resistance compared to filled grades.

Common Applications

Virgin PTFE is the go-to choice when purity is paramount. It is used extensively for gaskets, seals, and linings in the pharmaceutical, food, and petrochemical industries, as well as for high-frequency electrical insulation in cables and electronics.

Enhancing Performance: Modified and Filled Grades

To overcome the mechanical limitations of Virgin PTFE, various fillers are added to create composite materials with enhanced properties tailored to specific industrial needs.

Chemically Modified PTFE (TFM)

This isn't a filled grade but a copolymer of PTFE. This modification to the polymer chain itself results in a denser material with significantly less creep, a smoother surface finish, and improved resistance to permeation.

Glass-Filled PTFE

This is one of the most common filled grades. Reinforcing PTFE with glass fibers dramatically increases compressive strength and wear resistance. It maintains excellent chemical resistance, making it ideal for industrial components.

Common applications include piston rings, bushings, bearings, and slide plates, especially where dimensional stability under load is critical.

PEEK-Filled PTFE

PEEK (Polyetheretherketone) is a high-performance polymer used as a filler. This combination yields a material with exceptionally high stiffness, compressive strength, and wear resistance, even in demanding, high-temperature environments.

It is often specified for high-load bearings and seals in the aerospace and automotive industries.

Pigmented PTFE

This is the simplest variation. Pigments are added to Virgin PTFE primarily for color-coding and visibility. This modification does not significantly alter the mechanical, chemical, or electrical properties of the material.

Understanding the Trade-offs

Choosing a filled grade is not a simple upgrade; it involves strategic compromises. The enhancements in one area often come at the expense of another.

Purity vs. Strength

The primary trade-off is sacrificing purity for mechanical performance. Adding fillers like glass improves wear and compressive strength but introduces a foreign material into the otherwise pure PTFE matrix.

Impact on Chemical Resistance

While filled grades are still highly resistant to most chemicals, their overall resistance can be slightly diminished compared to Virgin PTFE. The filler material itself may be attacked by certain aggressive chemicals that pure PTFE would resist.

Reduced Electrical Performance

Virgin PTFE is one of the best electrical insulators known. The addition of most fillers, especially conductive or semi-conductive ones, will degrade these exceptional dielectric properties.

How to Select the Right PTFE Grade

Your choice should be driven entirely by the primary demand of your application.

- If your primary focus is maximum chemical purity or electrical insulation: Virgin PTFE is the definitive choice for laboratory equipment, food-grade seals, and high-frequency coaxial cables.

- If your primary focus is mechanical wear and compressive strength: Glass-filled or PEEK-filled PTFE are superior for components like bearings, industrial seals, and slide plates that operate under physical load.

- If your primary focus is reducing deformation without traditional fillers: Chemically Modified PTFE (TFM) offers an excellent balance for seals and linings where permeation and creep are concerns.

- If your primary focus is simple part identification or aesthetics: Pigmented PTFE serves this purpose without compromising the material's core performance.

Ultimately, selecting the correct PTFE grade ensures your component has the precise properties required to perform reliably in its intended environment.

Summary Table:

| Grade | Key Properties | Common Applications |

|---|---|---|

| Virgin PTFE | Maximum chemical resistance, best electrical insulation, low friction | Pharmaceutical seals, food-grade linings, high-frequency cables |

| Glass-Filled PTFE | High compressive strength, improved wear resistance, good chemical resistance | Piston rings, bushings, bearings, industrial seals |

| PEEK-Filled PTFE | Highest stiffness & wear resistance, excellent for high-temperatures | High-load aerospace/automotive bearings and seals |

| Chemically Modified (TFM) | Reduced creep, smoother surface, better permeation resistance | Seals and linings where deformation is a concern |

Need a custom PTFE component that perfectly matches your application's requirements?

At KINTEK, we specialize in manufacturing precision PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. We understand the critical trade-offs between purity, strength, and performance. Whether you need a prototype or a high-volume order, our custom fabrication expertise ensures you get the right grade of PTFE for superior reliability and longevity.

Contact our experts today to discuss your project and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications