For a direct comparison, stainless steel impellers are significantly cheaper and more widely available than their PTFE counterparts. Due to their prevalence as the industry standard, stainless steel options also come in a much broader range of styles and sizes that are readily in stock from most suppliers.

The choice between PTFE and stainless steel is not about finding the "best" material, but about aligning the material's properties with your application's demands. Stainless steel is the cost-effective default, while PTFE is a higher-cost, specialized solution for challenging chemical or adhesive environments.

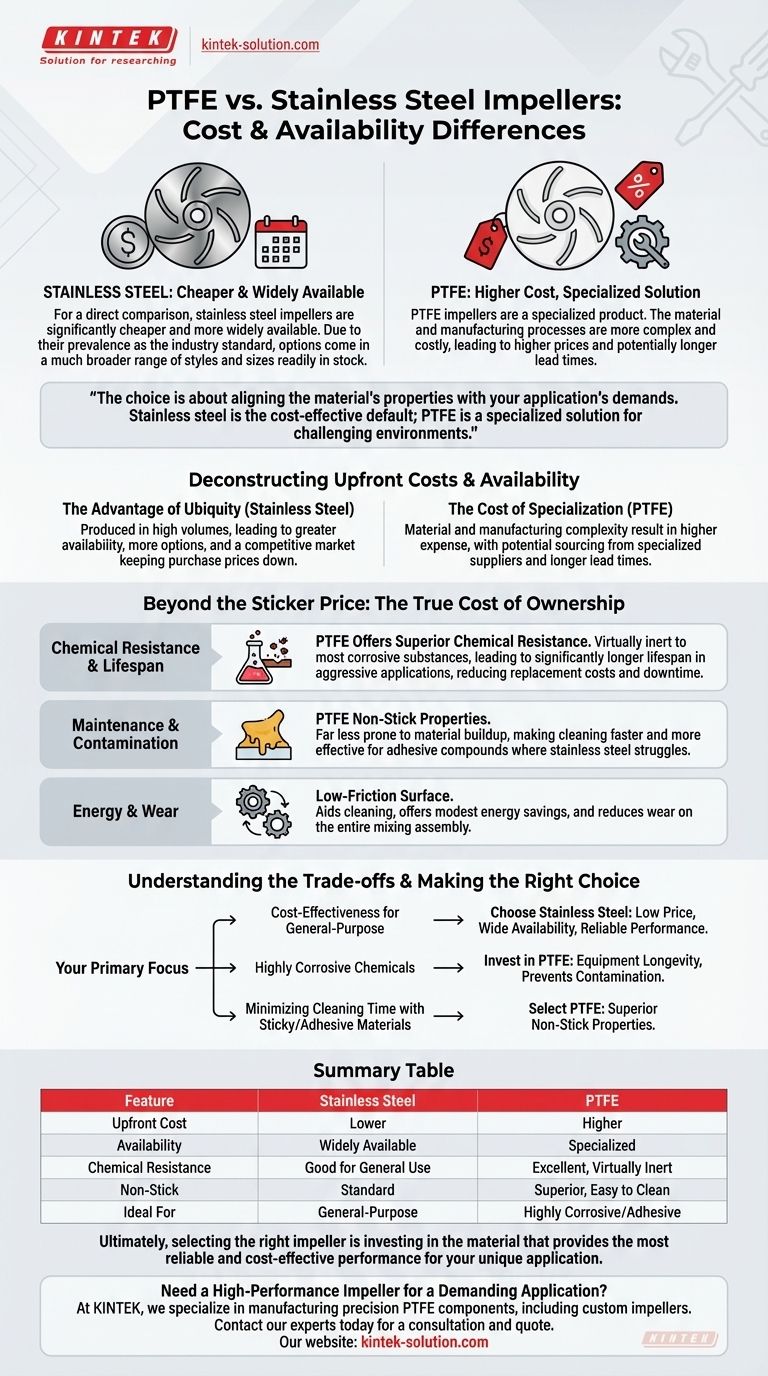

Deconstructing the Upfront Costs & Availability

The initial purchase decision is often driven by price and accessibility. In this regard, stainless steel has a clear and immediate advantage.

The Advantage of Ubiquity

Stainless steel is the standard material for many industrial and laboratory applications. This means it is produced in high volumes by numerous manufacturers.

This widespread production leads to greater availability, more style and size options, and a more competitive market, keeping purchase prices down.

The Cost of Specialization

PTFE impellers are a specialized product. The material itself and the manufacturing processes required are more complex and costly.

As a result, they are typically more expensive and may require sourcing from specialized suppliers, potentially leading to longer lead times.

Beyond the Sticker Price: The True Cost of Ownership

A technical advisor's role is to look past the initial purchase and evaluate the long-term operational value. Here, the unique properties of PTFE can justify its higher upfront cost.

Chemical Resistance and Lifespan

PTFE offers superior chemical resistance compared to nearly all other materials, including stainless steel. It is virtually inert when exposed to most corrosive substances.

For applications involving aggressive chemicals, a PTFE impeller will have a significantly longer lifespan, reducing replacement costs and downtime.

Maintenance and Contamination

PTFE's well-known non-stick properties are a major operational advantage. It is far less prone to material buildup or residue.

This makes cleaning faster and more effective, which is critical when working with moderately to highly adhesive compounds where stainless steel might struggle.

Energy and Wear

The low-friction surface of PTFE not only aids in cleaning but can also lead to modest energy savings and reduced wear on the entire mixing assembly over its operational life.

Understanding the Trade-offs

Choosing the right material requires an objective look at the benefits and limitations of each option in the context of your specific process.

The Case for Stainless Steel

For the vast majority of mixing applications that do not involve highly corrosive chemicals or significant adhesion challenges, stainless steel is the optimal choice.

Its robustness, ease of general cleaning, wide availability, and lower cost make it a reliable and economical workhorse.

When PTFE Becomes Essential

The higher cost and effort to source a PTFE impeller are justified only under specific conditions.

If your process involves chemicals that would corrode stainless steel or compounds that are difficult to clean due to adhesion, PTFE's properties shift from a luxury to a necessity.

Making the Right Choice for Your Application

Your decision should be based on a clear understanding of your operational needs and budget constraints.

- If your primary focus is cost-effectiveness for general-purpose mixing: Choose stainless steel for its low price, wide availability, and reliable performance.

- If your primary focus is working with highly corrosive chemicals: Invest in a PTFE impeller to ensure equipment longevity and prevent process contamination.

- If your primary focus is minimizing cleaning time with sticky or adhesive materials: Select a PTFE impeller for its superior non-stick properties.

Ultimately, selecting the right impeller is about investing in the material that provides the most reliable and cost-effective performance for your unique application.

Summary Table:

| Feature | Stainless Steel Impeller | PTFE Impeller |

|---|---|---|

| Upfront Cost | Lower | Higher |

| Availability | Widely available, many options | Specialized, may require sourcing |

| Chemical Resistance | Good for general use | Excellent, virtually inert |

| Non-Stick Properties | Standard | Superior, easy to clean |

| Ideal For | General-purpose, cost-sensitive applications | Highly corrosive or adhesive materials |

Need a High-Performance Impeller for a Demanding Application?

Choosing the right component is critical for your process's efficiency and longevity. At KINTEK, we specialize in manufacturing precision PTFE components—including custom impellers—for the semiconductor, medical, laboratory, and industrial sectors.

Whether you require a standard design or a custom-fabricated solution from prototype to high-volume production, we prioritize precision and performance to meet your exact specifications.

Let's discuss your application needs. Contact our experts today for a consultation and quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech