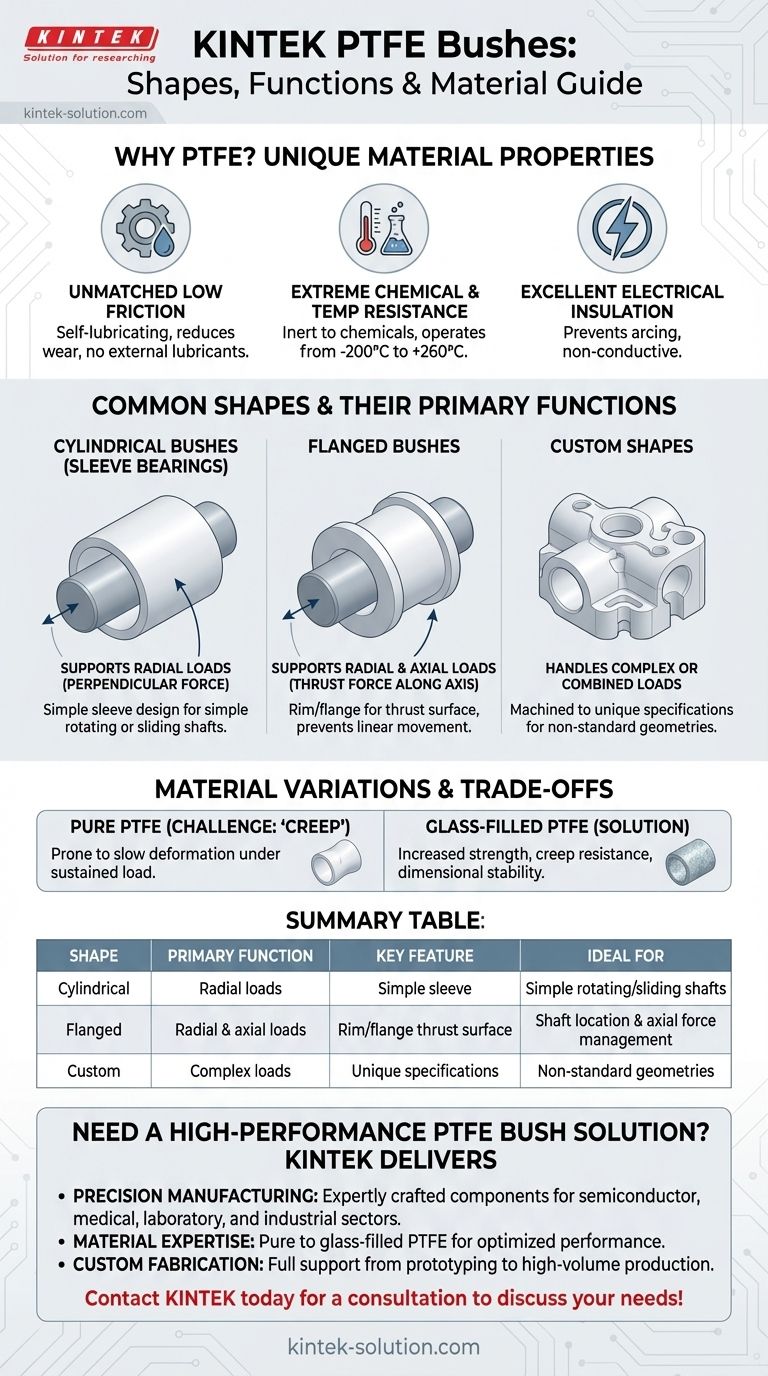

In short, the most common shapes for PTFE bushes are cylindrical and flanged. These two designs cover the vast majority of industrial applications, with custom shapes being manufactured for highly specific or unique equipment requirements.

The shape of a PTFE bush is dictated by its mechanical function: cylindrical bushes handle loads perpendicular to the shaft (radial loads), while flanged bushes handle both radial loads and thrust along the shaft's axis (axial loads).

Why Choose PTFE for Bushings?

Before selecting a shape, it's critical to understand why Polytetrafluoroethylene (PTFE) is chosen for these components. Its unique material properties make it an ideal choice for specific, demanding environments where other materials would fail.

Unmatched Low Friction

PTFE has one of the lowest coefficients of friction of any solid material. This creates a self-lubricating surface, reducing wear and eliminating the need for external lubricants in many applications.

Extreme Chemical and Temperature Resistance

This material is nearly inert, offering exceptional resistance to corrosive chemicals. With a high melting point around 347°C (657°F) and flexibility at low temperatures, it maintains its integrity across a vast operational window.

Excellent Electrical Insulation

PTFE is an outstanding electrical insulator. This property is crucial in applications where preventing electrical arcing or conductivity between components is a primary safety and operational requirement.

The Primary Shapes and Their Functions

The geometry of a PTFE bush is not arbitrary; it is directly related to the forces it is designed to manage.

Cylindrical Bushes (Sleeve Bearings)

A cylindrical bush is a simple sleeve. Its primary function is to serve as a bearing surface for a rotating or sliding shaft, supporting radial loads—forces that act perpendicular to the length of the shaft.

Flanged Bushes

A flanged bush is a cylinder with a rim or "flange" at one end. This flange provides a thrust surface, allowing the bush to handle axial loads—forces that act parallel to the shaft's axis. This design prevents linear movement along the shaft.

Custom Shapes

For non-standard applications, PTFE bushes can be machined into custom shapes. These are engineered to fit unique housing geometries or to handle complex, combined load scenarios that standard shapes cannot accommodate.

Understanding the Trade-offs and Material Variations

While standard PTFE is highly effective, it has limitations. Understanding these trade-offs is key to selecting the right material composition for your bush.

The Challenge of "Creep"

Pure PTFE, while flexible, can be prone to "creep"—a slow, permanent deformation under sustained load. This can be a significant issue in high-load applications where dimensional stability is critical.

The Role of Fillers (e.g., Glass)

To counteract creep and enhance mechanical properties, PTFE is often blended with fillers. Glass-filled PTFE bushes offer significantly increased mechanical strength, creep resistance, and dimensional stability. This makes them far better suited for applications with higher loads or tighter tolerances.

Material Equivalents

You may encounter specific formulations equivalent to materials like Rulon. These are specialized blends designed to meet standards for certain industries, such as FDA compliance for food processing, or to optimize for specific wear characteristics.

Making the Right Choice for Your Application

Your final selection depends entirely on the mechanical and environmental demands of your project.

- If your primary focus is supporting a simple rotating shaft: A standard cylindrical PTFE bush is the most direct and effective solution.

- If your primary focus is managing axial thrust or locating a shaft: A flanged PTFE bush is the necessary choice to handle forces along the shaft's axis.

- If your primary focus is strength and stability under high load: A glass-filled PTFE bush will provide the required resistance to creep and deformation.

Ultimately, choosing the correct PTFE bush requires matching the component's shape and material composition to the specific forces and conditions of your application.

Summary Table:

| Shape | Primary Function | Key Feature | Ideal For |

|---|---|---|---|

| Cylindrical | Supports radial loads (perpendicular to shaft) | Simple sleeve design | Simple rotating/sliding shafts |

| Flanged | Supports radial & axial loads (along shaft axis) | Rim/flange for thrust surface | Applications requiring shaft location & axial force management |

| Custom | Handles complex or combined loads | Machined to unique specifications | Non-standard housing geometries or specific load scenarios |

Need a High-Performance PTFE Bush Solution?

Whether your application requires standard cylindrical or flanged PTFE bushes, or a custom-machined shape for unique loads, KINTEK has the expertise to deliver.

We provide:

- Precision Manufacturing: Expertly crafted PTFE components (seals, liners, labware, and bushes) for the semiconductor, medical, laboratory, and industrial sectors.

- Material Expertise: From pure PTFE for unmatched chemical resistance to glass-filled PTFE for superior strength and creep resistance under high loads.

- Custom Fabrication: Full support from prototyping to high-volume production to meet your exact specifications and performance requirements.

Let us help you select the perfect PTFE bush for your project's mechanical and environmental demands.

Contact KINTEK today for a consultation to discuss your needs!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications