Teflon, known chemically as Polytetrafluoroethylene (PTFE), is far more than just a coating for cookware. It is a highly versatile fluoropolymer manufactured in several distinct forms, including solid sheets and films, flexible tapes, pipes for fluid transport, coated fabrics, and specialized coatings applied to other materials. This variety allows its unique properties to be leveraged across countless industrial, medical, and consumer applications.

The key to understanding Teflon is recognizing that its various product forms are all expressions of its core material properties: extreme chemical inertness, a very low coefficient of friction (non-stick), and high-temperature tolerance. The specific form—be it a tape, a sheet, or a coating—is simply the most effective way to apply those properties to a specific problem.

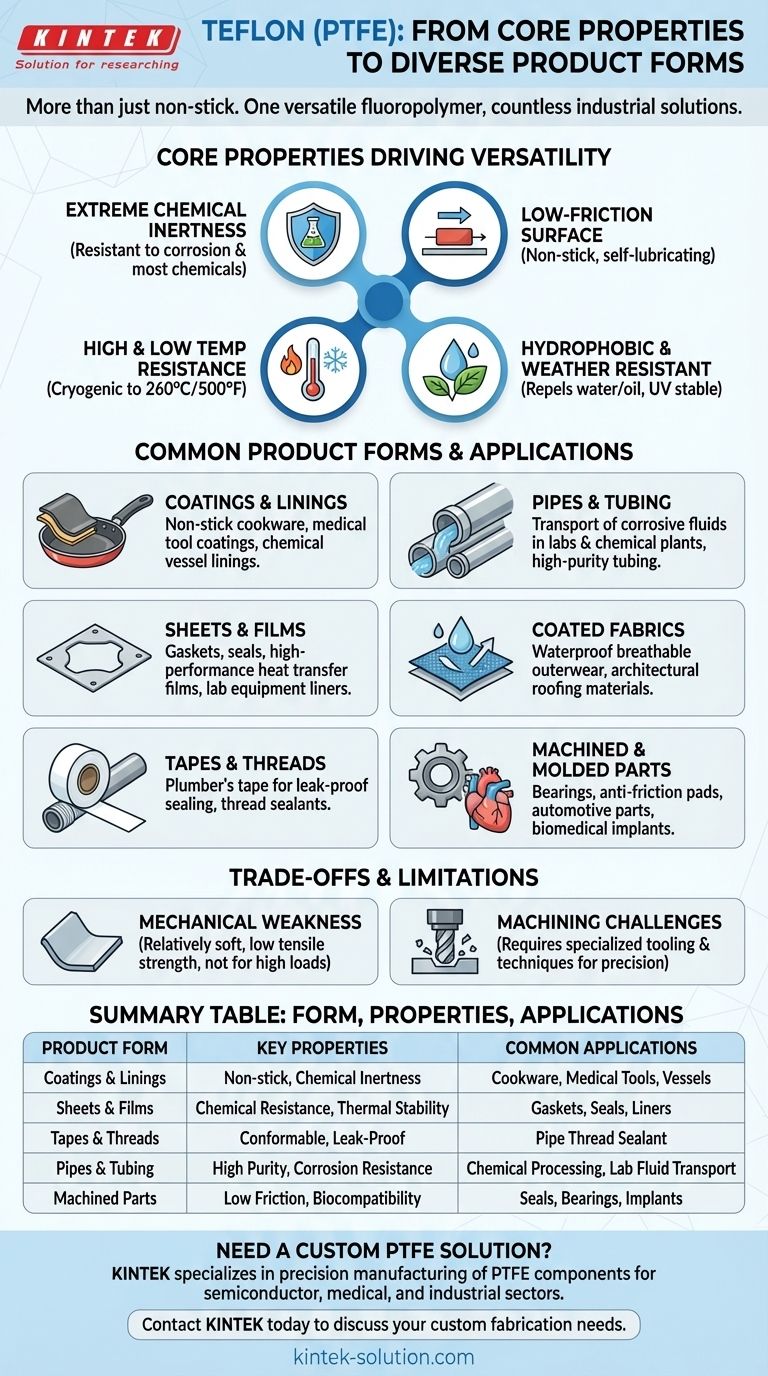

The Core Properties Driving Teflon's Versatility

The reason Teflon can be shaped into so many useful products is due to a unique combination of physical and chemical characteristics.

Extreme Chemical Inertness

Teflon is highly resistant to corrosion and does not react with the vast majority of chemicals. This makes it an ideal material for lining pipes, containers, and laboratory equipment that handle corrosive substances.

Low-Friction Surface

Famously known as "non-stick," PTFE has one of the lowest coefficients of friction of any solid. This property is critical not only for cookware but also for creating anti-friction devices, self-lubricating bearings, and low-resistance medical implants.

High and Low Temperature Resistance

PTFE performs reliably across a wide range of temperatures, from cryogenic lows to highs of around 260°C (500°F). This thermal stability makes it suitable for demanding applications in aerospace, such as heat shields, as well as high-heat industrial processes.

Hydrophobic and Weather Resistant

Teflon naturally repels water and oil, a property that makes it invaluable for producing waterproof, breathable fabrics. It is also highly resistant to weathering and UV degradation, ensuring long-term performance outdoors.

A Breakdown of Common Teflon Product Forms

These core properties are delivered through several common product forms, each tailored for a different set of applications.

Coatings and Linings

This is the most widely recognized form. A thin layer of PTFE is applied to a substrate, most commonly for non-stick cookware. It is also used to coat medical tools for smooth insertion and to line industrial vessels for chemical resistance.

Sheets and Films

Solid PTFE sheets and films are used in industrial settings. They serve as gaskets, seals, and lining materials. Thin films are also used in high-performance heat transfer processes where precise, non-contaminating results are required.

Tapes and Threads

The most common example is plumber's tape, used to seal pipe threads. The softness and chemical inertness of the material allow it to form a tight, leak-proof seal that won't degrade over time.

Pipes and Tubing

Due to its exceptional chemical resistance, Teflon is used to manufacture pipes and tubing for transporting highly corrosive or high-purity fluids in laboratories and chemical processing plants.

Coated Fabrics

By applying a thin, porous layer of Teflon to fabric, manufacturers can create materials that are both waterproof and breathable. This is common in high-performance outerwear and architectural roofing materials.

Machined and Molded Parts

Solid stock forms of PTFE can be machined (turned, milled, or drilled) into custom components. These parts are used for everything from automotive components and anti-friction pads to biomedical implants like artificial heart valves and joints.

Understanding the Trade-offs and Limitations

While incredibly useful, Teflon is not a perfect material for every situation. Understanding its limitations is key to using it effectively.

Mechanical Weakness

PTFE is a relatively soft polymer. It has low tensile strength and is not suitable for high-load structural applications where rigidity and hardness are required.

Machining Challenges

The softness that makes Teflon useful for seals also makes it challenging to machine with high precision. It requires specialized tooling and techniques to avoid deformation and achieve clean cuts.

Vulnerability to Specific Chemicals

While famously inert, Teflon is not completely invincible. It can be damaged by highly reactive alkali metals and certain high-temperature, high-pressure halogenated agents.

Choosing the Right Form for Your Application

Selecting the correct form of Teflon depends entirely on the problem you need to solve.

- If your primary focus is surface performance: A Teflon coating is likely the most effective solution for non-stick, low-friction, or hydrophobic needs.

- If your primary focus is fluid transport or sealing: Teflon pipes, tubing, and tape provide unmatched chemical resistance for handling corrosive liquids and sealing threads.

- If your primary focus is creating a custom part: Machined or molded solid PTFE is necessary for components like seals, bearings, or specialized biomedical implants.

By understanding these forms, you can leverage Teflon's unique properties to solve a vast range of engineering and design challenges.

Summary Table:

| Product Form | Key Properties | Common Applications |

|---|---|---|

| Coatings & Linings | Non-stick, Chemical Inertness | Cookware, Medical Tools, Industrial Vessels |

| Sheets & Films | Chemical Resistance, Thermal Stability | Gaskets, Seals, Lab Equipment Liners |

| Tapes & Threads | Conformable, Leak-Proof | Pipe Thread Sealant (Plumber's Tape) |

| Pipes & Tubing | High Purity, Corrosion Resistance | Chemical Processing, Laboratory Fluid Transport |

| Machined Parts | Low Friction, Biocompatibility | Seals, Bearings, Automotive, Medical Implants |

Need a Custom PTFE Solution?

KINTEK specializes in the precision manufacturing of PTFE components—from seals and liners to complex labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you require a prototype or high-volume production, our expertise ensures your application benefits from Teflon's superior chemical resistance, non-stick properties, and thermal stability.

Contact KINTEK today to discuss your custom fabrication needs and get a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications