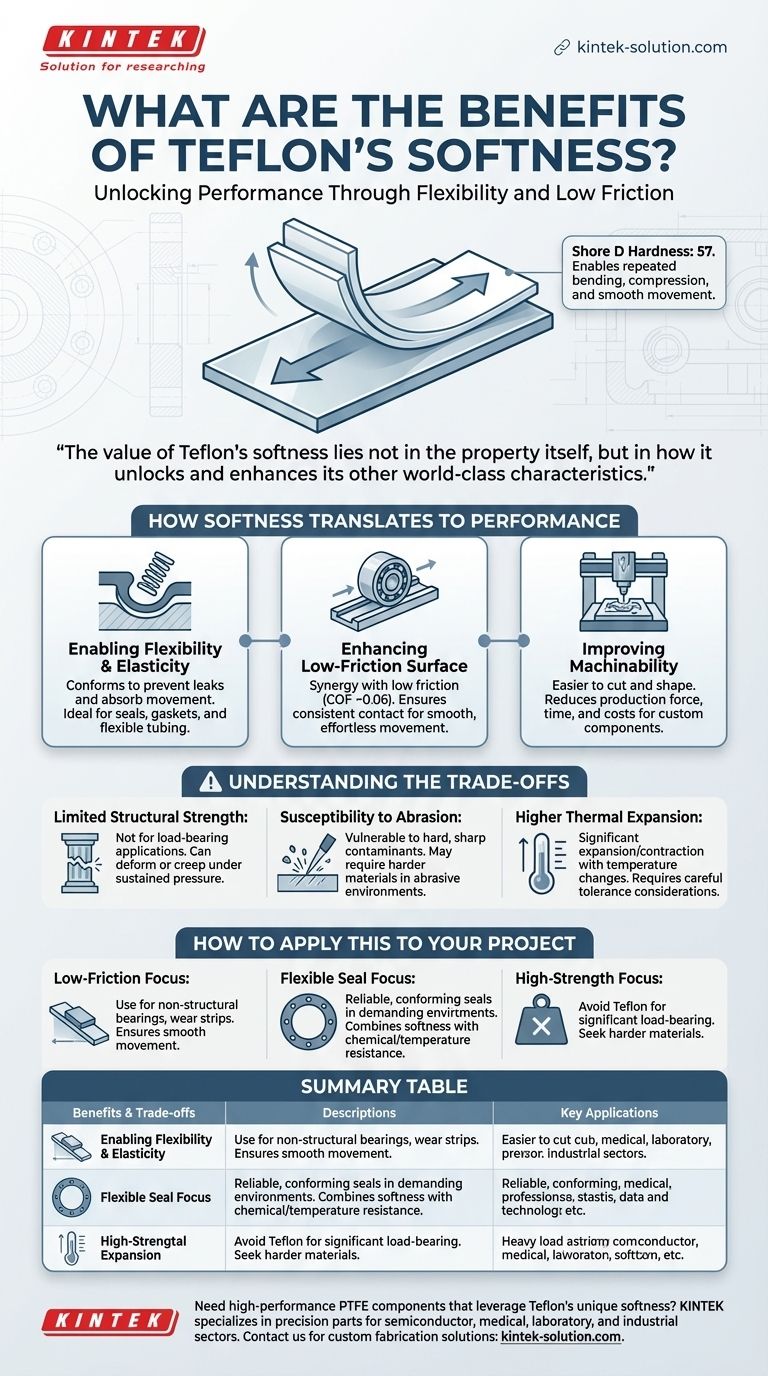

The primary benefit of Teflon's softness is the exceptional flexibility it provides, which works in concert with its famously low-friction surface to enable smooth, reliable movement in dynamic applications. With a Shore D hardness of just 57, this relative softness allows Polytetrafluoroethylene (PTFE) to conform to surfaces and bend repeatedly where more rigid materials would crack or fail. This unique combination makes it an elite material for parts that must bend, compress, or slide without wear.

The value of Teflon's softness lies not in the property itself, but in how it unlocks and enhances its other world-class characteristics. Its flexibility allows the low-friction, non-stick, and chemically inert surface to be applied in dynamic, high-wear environments where harder, more brittle materials are unsuitable.

How Softness Translates to Performance

Teflon's softness is not a standalone feature but a foundational property that directly contributes to its most valued engineering capabilities. It's the key that allows its other properties to perform in a wider range of applications.

Enabling Flexibility and Elasticity

The most direct benefit of softness is flexibility. Teflon can be used in dynamic applications where parts must bend, flex, or compress to function.

This makes it an ideal material for components like seals, gaskets, and flexible tubing that need to conform to a surface to prevent leaks or absorb movement.

Enhancing its Low-Friction Surface

Softness works in synergy with Teflon's extremely low coefficient of friction (around 0.06 against steel).

A slightly compliant and flexible surface can maintain more consistent contact in applications like sliding bearings or guide rails. This ensures the low-friction property is engaged uniformly, promoting smooth, effortless movement and reducing wear.

Improving Machinability

From a manufacturing perspective, softness is a significant advantage. Softer materials require less force to cut and shape.

This makes Teflon relatively easy to machine into complex custom components compared to harder plastics or metals. The result is often faster production times and lower manufacturing costs.

Understanding the Trade-offs

No material is perfect, and the properties that make Teflon uniquely useful also create its limitations. Understanding these trade-offs is critical for proper material selection.

Limited Structural Strength

The most significant trade-off for softness is a lack of structural rigidity. Teflon is not suitable for load-bearing applications.

Under sustained pressure, it can deform or "creep," meaning it will slowly change shape over time. This makes it a poor choice for components that must maintain precise dimensions under load.

Susceptibility to Abrasion

While Teflon has extremely low friction, it is not highly resistant to abrasion. Its soft surface can be scratched or gouged by hard, sharp contaminants.

In environments with abrasive particles, a harder material may be necessary, even if it has a higher coefficient of friction.

Higher Thermal Expansion

Compared to metals and harder engineering plastics, Teflon expands and contracts more significantly with changes in temperature.

Designers must account for this higher coefficient of thermal expansion in assemblies with tight tolerances to prevent parts from binding or becoming loose as temperatures fluctuate.

How to Apply This to Your Project

Your specific goal will determine whether Teflon's unique combination of properties is the right solution for your challenge.

- If your primary focus is a low-friction sliding component: Teflon's softness ensures excellent surface contact and smooth movement, making it ideal for non-structural bearings, slide plates, and wear strips.

- If your primary focus is a flexible seal or gasket: Its combination of softness and extreme chemical and temperature resistance provides a reliable, conforming seal in demanding industrial environments.

- If your primary focus is a high-strength structural part: You should look to other materials, as Teflon's softness makes it unsuitable for any significant load-bearing applications.

Ultimately, viewing Teflon's softness as an enabler for its other properties is the key to leveraging it correctly as a high-performance engineering material.

Summary Table:

| Benefit | Description | Key Application |

|---|---|---|

| Flexibility & Elasticity | Allows parts to bend, compress, and conform to surfaces without cracking. | Seals, gaskets, flexible tubing |

| Enhanced Low-Friction | Softness ensures consistent surface contact for smooth, low-wear movement. | Sliding bearings, guide rails, wear strips |

| Improved Machinability | Easier to cut and shape, reducing production time and cost for custom parts. | Complex custom components, prototypes |

| Trade-offs | Limited structural strength, susceptibility to abrasion, higher thermal expansion. | Not suitable for load-bearing applications |

Need high-performance PTFE components that leverage Teflon's unique softness? KINTEK specializes in manufacturing precision PTFE parts like seals, liners, and labware for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures you get components optimized for flexibility, low friction, and durability. Contact us today to discuss your project requirements and benefit from our precision production capabilities!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions