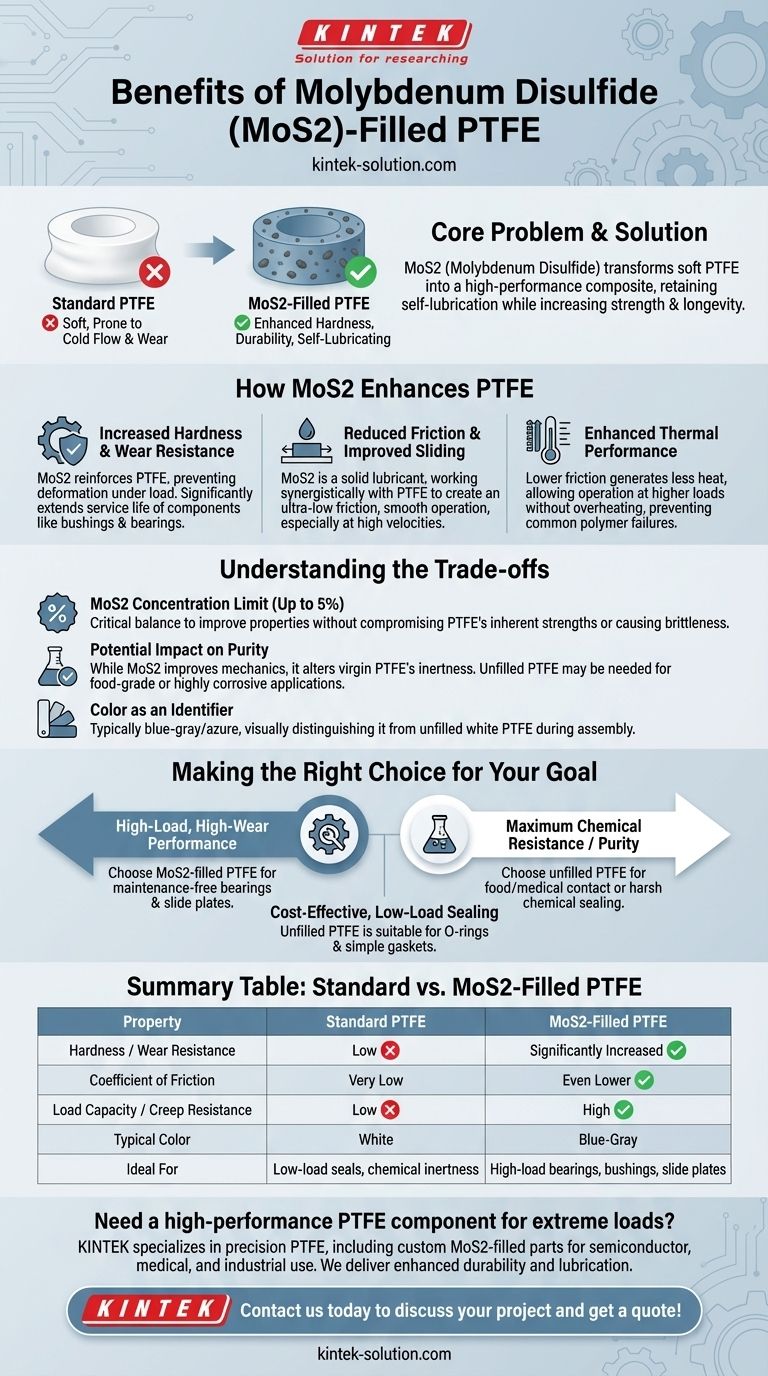

In short, molybdenum disulfide (MoS2) is added to PTFE to significantly improve its mechanical properties for demanding applications. This filler enhances the material's hardness and resistance to wear and deformation, while also further reducing its already low coefficient of friction. The resulting composite is a more durable, high-performance version of standard PTFE.

The core problem with standard PTFE is its softness; it can deform or wear quickly under high loads. Adding molybdenum disulfide (MoS2) as a filler creates a composite material that retains PTFE's self-lubricating nature while dramatically increasing its strength and longevity.

Why Unfilled PTFE Often Isn't Enough

The Weakness of a Soft Material

Polytetrafluoroethylene (PTFE) is famous for its extremely low friction—it's one of the most slippery materials known. However, this benefit comes with a major drawback: it is a relatively soft polymer.

Under significant mechanical stress or pressure, pure PTFE is prone to "cold flow," or creep, where the material slowly deforms. It also has poor abrasion resistance, meaning it wears down quickly in high-cycle sliding applications.

How Molybdenum Disulfide Enhances PTFE

Adding a small amount (typically up to 5%) of molybdenum disulfide transforms PTFE into a more robust engineering material. MoS2 acts as both a reinforcing agent and a secondary solid lubricant.

Increased Hardness and Wear Resistance

The fine particles of MoS2 distributed within the PTFE matrix act as a structural reinforcement. This makes the composite material physically harder and more resistant to deformation under load.

This increased hardness directly translates to superior wear resistance. The material can withstand more friction and abrasion before it begins to break down, significantly extending the service life of components like bushings and bearings.

Reduced Friction and Improved Sliding

Molybdenum disulfide is itself an excellent solid lubricant. It works synergistically with PTFE to create an even more effective self-lubricating surface.

When a MoS2-filled PTFE part is in motion, it deposits a microscopic lubricating film on both its own surface and the mating surface. This film reduces the static and dynamic coefficients of friction, allowing for smoother operation, especially under high loads and velocities.

Enhanced Thermal Performance

The improved efficiency and lower friction also mean that less heat is generated in the system. This allows MoS2-filled PTFE components to operate effectively at higher loads without overheating, which is a common point of failure for many polymer-based parts.

Understanding the Trade-offs

The Concentration Limit

The references specify a concentration of up to 5% MoS2. This is a critical detail. While MoS2 improves mechanical properties, adding too much can make the composite brittle and compromise the inherent strengths of the PTFE matrix. The 5% level is an optimized balance.

Potential Impact on Purity and Inertness

Virgin PTFE is known for its exceptional chemical inertness and status as a food-grade material. The addition of any filler, including MoS2, alters this composition. For applications in highly corrosive environments or those requiring absolute purity (like medical or food processing), unfilled PTFE may still be the required choice.

Color as an Identifier

MoS2-filled PTFE is typically blue-gray or azure in color. While not a performance benefit, this provides a simple and effective way to visually distinguish it from unfilled (white) PTFE or other filled variants (like glass-filled or carbon-filled PTFE), preventing incorrect material use during assembly or maintenance.

Making the Right Choice for Your Goal

When selecting a material, your primary application dictates the best choice.

- If your primary focus is high-load, high-wear performance: Choose MoS2-filled PTFE. Its superior hardness and self-lubricating synergy make it ideal for maintenance-free bushings, bearings, and slide plates.

- If your primary focus is maximum chemical resistance or electrical insulation: Choose unfilled (virgin) PTFE. The absence of fillers ensures the highest possible purity and dielectric strength.

- If your primary focus is cost-effective, low-load sealing: Unfilled PTFE is often perfectly adequate for applications like O-rings or simple gaskets where mechanical wear is not the main concern.

Ultimately, adding molybdenum disulfide elevates PTFE from a simple low-friction polymer to a high-strength, self-lubricating engineering material designed for demanding mechanical systems.

Summary Table:

| Property | Standard PTFE | MoS2-Filled PTFE |

|---|---|---|

| Hardness / Wear Resistance | Low | Significantly Increased |

| Coefficient of Friction | Very Low | Even Lower |

| Load Capacity / Creep Resistance | Low | High |

| Typical Color | White | Blue-Gray |

| Ideal For | Low-load seals, chemical inertness | High-load bearings, bushings, slide plates |

Need a high-performance PTFE component that can handle extreme loads and wear?

KINTEK specializes in manufacturing precision PTFE components, including custom MoS2-filled parts for the semiconductor, medical, laboratory, and industrial sectors. We deliver the enhanced durability and superior lubrication your application demands, from prototypes to high-volume production.

Contact us today to discuss your project and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications