Reinforcing Polytetrafluoroethylene (PTFE) with carbon and graphite dramatically enhances its mechanical properties for demanding applications. This composite material offers significantly improved wear resistance, greater dimensional stability under load, and better performance at high temperatures and pressures compared to virgin PTFE, all while maintaining excellent self-lubricating characteristics.

By adding carbon and graphite fillers, you are fundamentally transforming PTFE from a soft, compliant polymer into a robust engineering composite. This enhancement is a calculated trade-off, sacrificing some of PTFE's inherent properties to gain the mechanical strength required for dynamic seals, bearings, and compressor components.

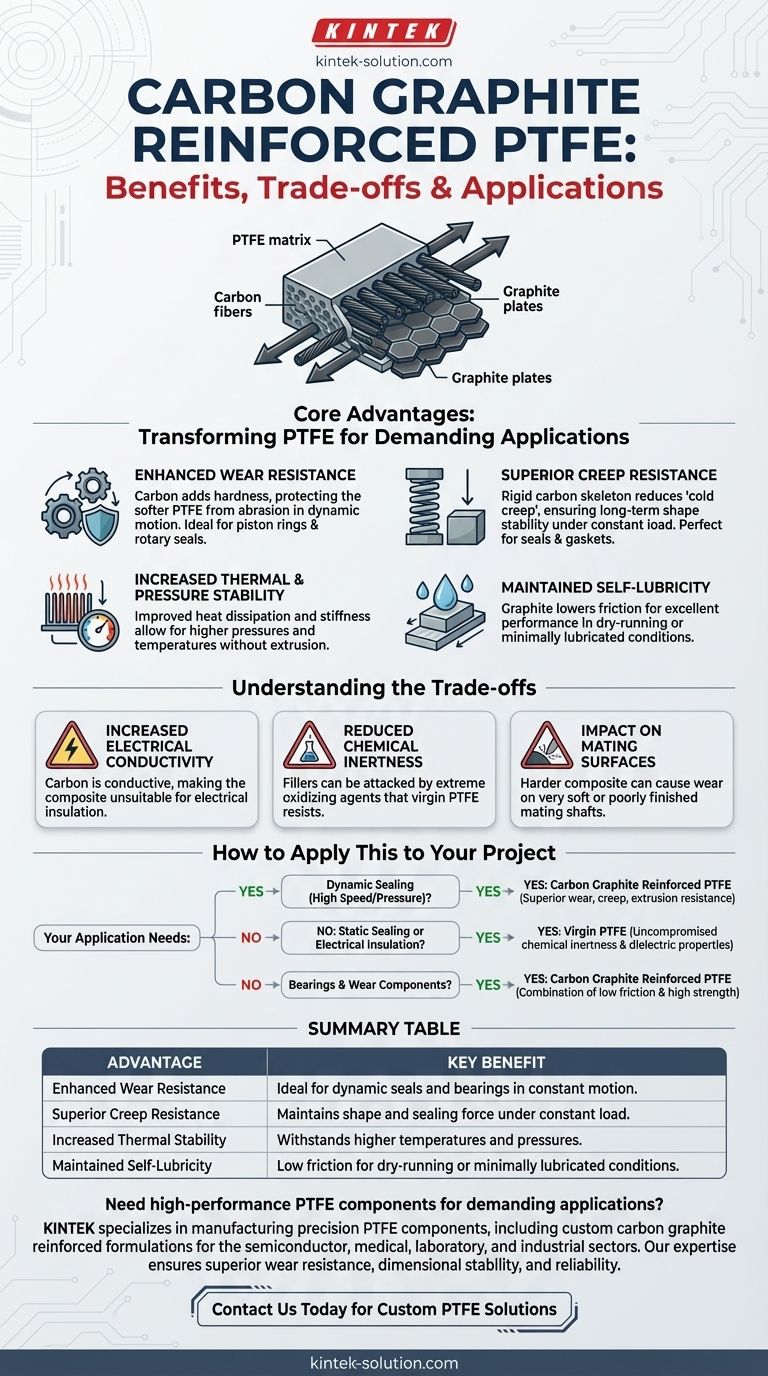

The Core Advantages of Carbon Graphite Reinforcement

Adding fillers like carbon and graphite creates a composite material where the PTFE matrix is supported by a more rigid internal structure. This synergy is what produces the material's superior performance characteristics.

Enhanced Wear Resistance

The carbon component, being significantly harder than the PTFE matrix, provides excellent wear resistance. It acts as a sacrificial element that protects the softer polymer from abrasion during dynamic use.

This makes the material ideal for components like piston rings and rotary seals that experience constant motion and friction.

Superior Creep Resistance

Virgin PTFE is susceptible to "cold creep," a slow deformation that occurs when the material is under a constant load, even at room temperature.

The rigid carbon filler acts as a skeleton within the PTFE, drastically reducing creep. This ensures that components like seals and gaskets maintain their shape and sealing force over time.

Increased Thermal and Pressure Stability

The addition of carbon improves the material's ability to dissipate heat, a critical factor in high-speed applications where friction generates significant heat.

This enhanced thermal conductivity, combined with the material's increased stiffness, allows it to withstand higher pressures without extruding or deforming, a common failure mode for un-filled PTFE seals.

Maintained Self-Lubricity

While carbon provides strength, graphite provides enhanced lubricity. Graphite is an excellent solid lubricant, which lowers the coefficient of friction, especially against softer metal shafts.

This quality reduces stick-slip behavior during startup and allows for reliable performance in dry-running or minimally lubricated conditions. A common formulation is 23% carbon and 2% graphite to balance strength and low friction.

Understanding the Trade-offs

Reinforcing PTFE is not without its compromises. Understanding these limitations is crucial for proper material selection.

Increased Electrical Conductivity

Virgin PTFE is an excellent electrical insulator. However, carbon is electrically conductive.

The addition of carbon and graphite fillers makes the composite material conductive, rendering it unsuitable for any application that requires electrical insulation.

Reduced Chemical Inertness

While still highly resistant to most chemicals, the fillers can be attacked by certain aggressive media that virgin PTFE would otherwise resist.

For applications involving extreme oxidizing agents or chemicals known to react with carbon, virgin PTFE remains the safer choice.

Impact on Mating Surfaces

The composite is harder and more abrasive than virgin PTFE. While the graphite helps protect softer shafts, the overall hardness must be considered.

Using this material against a very soft or poorly finished mating surface can cause premature wear on the shaft itself.

How to Apply This to Your Project

Your choice between virgin PTFE and a carbon graphite composite depends entirely on the mechanical and environmental demands of your application.

- If your primary focus is dynamic sealing (high speed/pressure): Carbon graphite reinforced PTFE is an excellent choice due to its superior wear, creep, and extrusion resistance.

- If your primary focus is static sealing or electrical insulation: Virgin PTFE is the better material, as its chemical inertness and dielectric properties are uncompromised.

- If your primary focus is bearings and wear components: The combination of low friction from the graphite and high strength from the carbon makes this composite ideal for long-lasting, self-lubricating parts.

Ultimately, choosing carbon graphite reinforced PTFE is a strategic decision to gain mechanical resilience and dimensional stability where virgin PTFE falls short.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Enhanced Wear Resistance | Ideal for dynamic seals and bearings in constant motion. |

| Superior Creep Resistance | Maintains shape and sealing force under constant load. |

| Increased Thermal Stability | Withstands higher temperatures and pressures. |

| Maintained Self-Lubricity | Low friction for dry-running or minimally lubricated conditions. |

Need high-performance PTFE components for demanding applications?

At KINTEK, we specialize in manufacturing precision PTFE components, including custom carbon graphite reinforced formulations for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your seals, liners, and labware deliver superior wear resistance, dimensional stability, and reliability—from prototypes to high-volume orders.

Contact us today to discuss how our custom PTFE solutions can enhance your project's performance and longevity.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications