In precision manufacturing, Teflon (PTFE) rods are a foundational material used in CNC machining to produce a wide range of high-performance custom components. Common applications include creating low-friction bearings, chemically resistant seals, durable guides, and high-voltage electrical insulators. The material's value comes from its unique combination of properties, allowing it to be easily machined into parts that solve specific engineering challenges where other plastics or metals would fail.

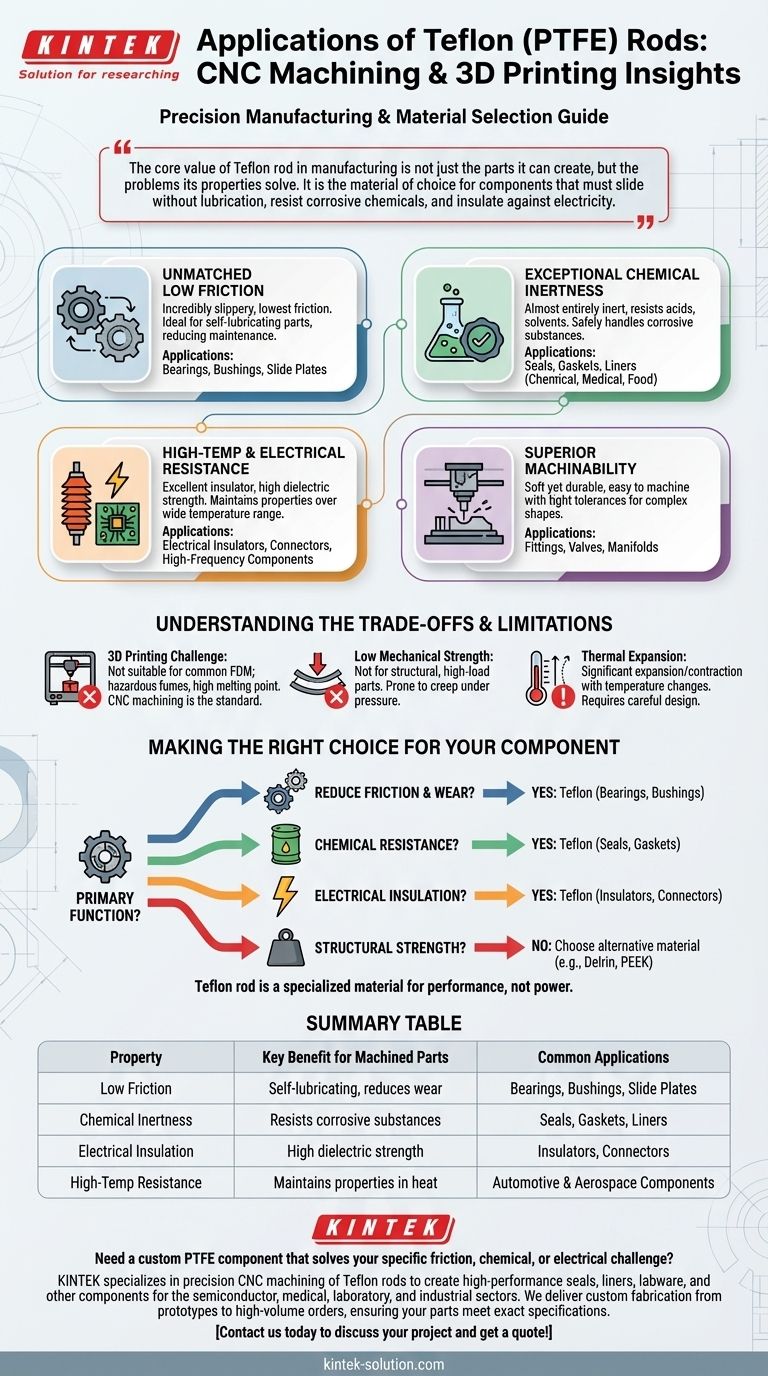

The core value of Teflon rod in manufacturing is not just the parts it can create, but the problems its properties solve. It is the material of choice for components that must slide without lubrication, resist corrosive chemicals, and insulate against electricity, making it indispensable for custom parts in demanding environments.

Why Teflon is a Primary Choice for Machined Components

Teflon, or Polytetrafluoroethylene (PTFE), is not chosen for its strength but for its unique combination of performance characteristics. Understanding these properties is key to knowing why it is so widely used for specific machined parts.

Unmatched Low Friction

Teflon has one of the lowest coefficients of friction of any solid material, making it incredibly "slippery." This property is essential for parts that need to slide against each other with minimal resistance and wear.

This is the primary reason it is used for bearings, bushings, and slide plates in machinery. These components are often self-lubricating, reducing the need for maintenance and increasing the lifespan of the equipment.

Exceptional Chemical Inertness

PTFE is almost entirely inert, meaning it does not react with the vast majority of industrial chemicals, solvents, and acids.

This makes it an ideal material for seals, gaskets, and liners in the chemical processing, medical, and food industries. Components machined from Teflon can safely handle corrosive substances without degrading.

High-Temperature and Electrical Resistance

Teflon can maintain its properties over a wide temperature range and is an excellent electrical insulator. It has a high dielectric strength, meaning it can withstand high voltages without breaking down.

This leads to its use in creating custom electrical insulators, connectors, and components for high-frequency electronics. Its heat resistance also makes it suitable for parts in automotive and aerospace applications.

Superior Machinability

Despite its durability, Teflon is a relatively soft material that is easy to machine. CNC mills and lathes can cut it cleanly to create complex shapes and achieve very tight tolerances.

This ease of shaping allows for the cost-effective production of highly specific, custom parts like fittings, valves, and manifolds without compromising the material's inherent strengths.

Understanding the Trade-offs and Limitations

While Teflon is a versatile material, it is not a universal solution. Acknowledging its limitations is critical for successful application design.

The Challenge with 3D Printing

While the question includes 3D printing, it's crucial to understand that standard Teflon (PTFE) rod is not suitable for common 3D printing methods like Fused Deposition Modeling (FDM). Its extremely high melting point and the release of hazardous fumes during heating make it incompatible with conventional printers.

For creating Teflon parts, CNC machining from solid rod or bar stock remains the definitive and standard manufacturing process.

Low Mechanical Strength

Teflon is not a structural material. It is relatively soft and has poor tensile strength compared to other engineering plastics like Delrin or PEEK.

It should not be used for high-load applications where rigidity and strength are the primary requirements. It is prone to "creep," or deformation under sustained pressure.

Thermal Expansion

Teflon has a relatively high coefficient of thermal expansion, meaning it expands and contracts significantly with temperature changes. This must be accounted for in designs that require tight tolerances in fluctuating thermal environments.

Making the Right Choice for Your Component

Selecting the right material is about matching its properties to the primary function of the part. Teflon should be your go-to choice when its unique characteristics directly solve your core engineering problem.

- If your primary focus is reducing friction and wear: Teflon is an ideal choice for self-lubricating bearings, bushings, and sliding guides.

- If your primary focus is chemical resistance: Use Teflon for seals, gaskets, and liners that will be exposed to corrosive substances.

- If your primary focus is electrical insulation: Teflon's high dielectric strength makes it perfect for custom insulators, connectors, and high-frequency components.

- If your primary focus is structural strength: You should choose a different material, as Teflon is soft and will deform under significant mechanical load.

Ultimately, Teflon rod is a specialized material for machining parts where performance, not power, is the deciding factor.

Summary Table:

| Property | Key Benefit for Machined Parts | Common Applications |

|---|---|---|

| Low Friction | Self-lubricating, reduces wear | Bearings, Bushings, Slide Plates |

| Chemical Inertness | Resists corrosive substances | Seals, Gaskets, Liners |

| Electrical Insulation | High dielectric strength | Insulators, Connectors |

| High-Temp Resistance | Maintains properties in heat | Automotive & Aerospace Components |

Need a custom PTFE component that solves your specific friction, chemical, or electrical challenge?

KINTEK specializes in precision CNC machining of Teflon rods to create high-performance seals, liners, labware, and other components for the semiconductor, medical, laboratory, and industrial sectors. We deliver custom fabrication from prototypes to high-volume orders, ensuring your parts meet exact specifications.

Contact us today to discuss your project and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials