In demanding sealing applications, PTFE backup rings serve a critical role by preventing the extrusion of softer seals, like rubber O-rings, under high pressure and temperature. Their key advantages stem from PTFE's unique material properties: exceptional chemical resistance, an extremely low coefficient of friction, and stability across a wide temperature range, making them indispensable in hydraulic, pneumatic, and chemical processing systems.

A PTFE backup ring is not the primary seal itself; rather, it is a crucial support component that enables a softer, more flexible primary seal to function reliably under extreme conditions that would otherwise cause it to fail.

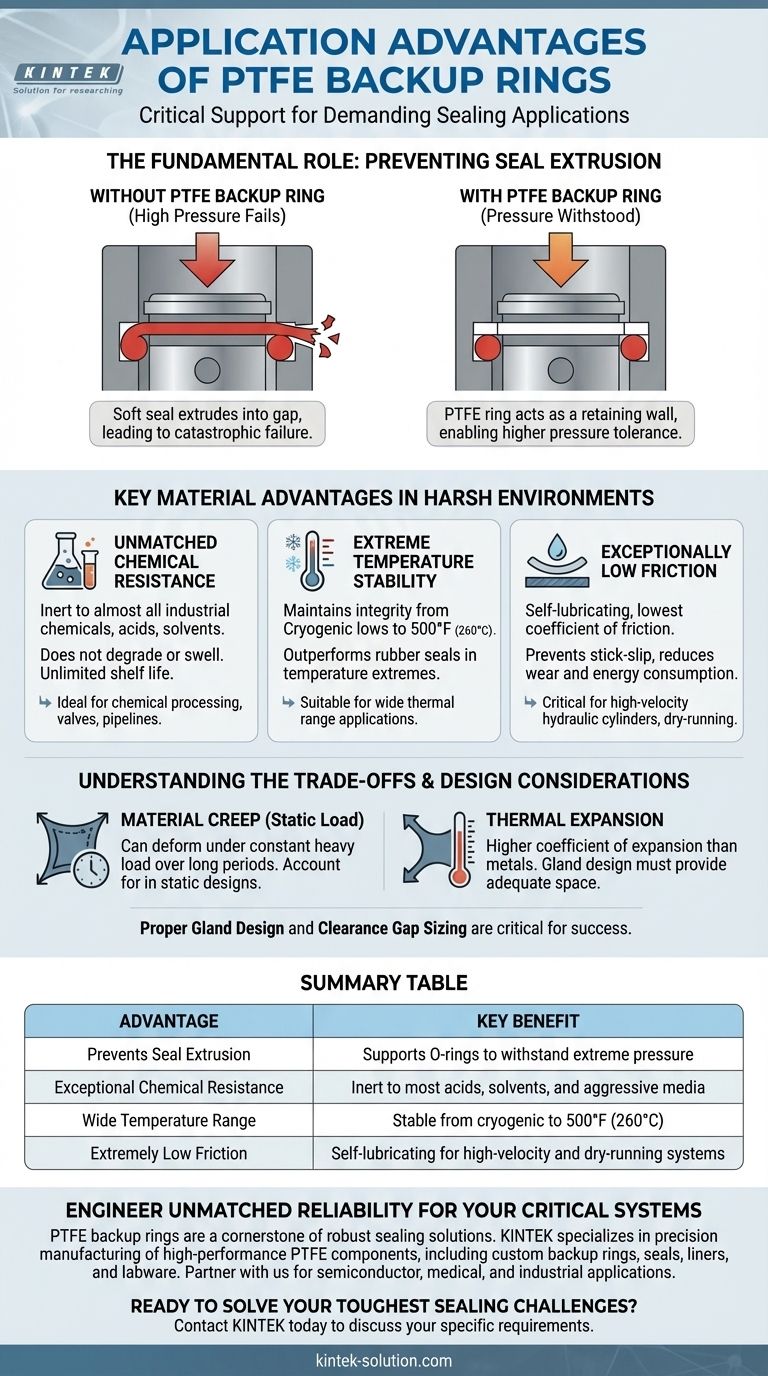

The Fundamental Role: Preventing Seal Extrusion

The primary purpose of any backup ring is to solve a specific mechanical problem: the extrusion of a primary seal into the clearance gap between moving parts.

The Problem of High Pressure

Under significant pressure, a soft elastomeric seal, such as a standard O-ring, is forced to deform. If a clearance gap exists between the piston and the cylinder bore, this pressure can push the O-ring material into that gap. This process, called extrusion, quickly shreds or "nibs" the seal, leading to catastrophic failure.

The PTFE Solution

A PTFE backup ring is installed in the gland alongside the O-ring, typically on the low-pressure side. Because PTFE is a significantly harder and more rigid material than the elastomer, it physically blocks the clearance gap. It acts as a retaining wall, preventing the O-ring from being pushed into the gap and allowing the sealing system to withstand much higher pressures.

Key Material Advantages in Harsh Environments

PTFE's inherent properties make it the superior choice for backup rings when standard materials like nylon or other plastics would fail.

Unmatched Chemical Resistance

PTFE is virtually inert to almost all industrial chemicals, acids, solvents, and hydraulic fluids. This makes it the default choice for chemical processing equipment, valves, and pipelines where aggressive media are present. Unlike many elastomers, PTFE does not degrade or swell with chemical exposure, offering an almost unlimited shelf life and operational stability.

Extreme Temperature Stability

PTFE backup rings maintain their integrity and performance in environments ranging from cryogenic lows to high temperatures of up to 500°F (260°C). This far exceeds the operational limits of most rubber seals, which can become brittle at low temperatures or soften and degrade at high temperatures.

Exceptionally Low Friction

PTFE possesses one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice. It is self-lubricating, which is critical in high-velocity hydraulic cylinders or in dry-running applications where external lubrication is impossible. This property prevents stick-slip behavior, reduces wear on moving parts, and lowers the energy required to operate the system.

Understanding the Trade-offs and Design Considerations

While highly effective, PTFE backup rings are not a universal solution. Proper implementation requires understanding their material limitations.

Material Creep Under Static Load

Like many polymers, PTFE can be subject to creep—a slow, permanent deformation when placed under a constant, heavy load over a long period. In static sealing applications with extreme, sustained pressure, this must be accounted for during the design phase.

Thermal Expansion

PTFE has a higher coefficient of thermal expansion than the metals it is typically paired with. This means it will expand and contract more with temperature changes. The design of the seal gland must provide adequate space to accommodate this expansion without compromising the seal.

The Importance of Proper Gland Design

The effectiveness of a PTFE backup ring is entirely dependent on the correct sizing of the clearance gap. If the gap is too large, even a PTFE ring can eventually be forced into it and fail under extreme pressure. Adhering to established engineering standards for gland dimensions is critical for success.

Choosing PTFE Backup Rings for Your Application

The decision to use a PTFE backup ring should be based on the specific demands of your system.

- If your primary focus is reliability in high-pressure hydraulics: Use PTFE backup rings to prevent O-ring extrusion and dramatically increase the pressure rating of your sealing system.

- If your primary focus is performance in chemically aggressive or high-temperature environments: PTFE's chemical inertness and thermal stability provide a lifespan and reliability that elastomers cannot match.

- If your primary focus is improving efficiency and simplifying maintenance: The low-friction properties reduce energy loss, while split (scarf-cut) ring designs allow for easy installation without system disassembly.

By leveraging PTFE backup rings, you transition from merely sealing a system to engineering its long-term reliability and performance.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Prevents Seal Extrusion | Supports O-rings to withstand extreme pressure |

| Exceptional Chemical Resistance | Inert to most acids, solvents, and aggressive media |

| Wide Temperature Range | Stable from cryogenic to 500°F (260°C) |

| Extremely Low Friction | Self-lubricating for high-velocity and dry-running systems |

Engineer Unmatched Reliability for Your Critical Systems

PTFE backup rings are a cornerstone of robust sealing solutions in demanding environments. At KINTEK, we specialize in the precision manufacturing of high-performance PTFE components, including custom backup rings, seals, liners, and labware.

Our expertise ensures your hydraulic, pneumatic, or chemical processing systems achieve peak performance and longevity. We partner with the semiconductor, medical, laboratory, and industrial sectors to deliver custom fabrication from prototypes to high-volume orders.

Ready to solve your toughest sealing challenges? Contact KINTEK today to discuss your specific requirements and discover how our PTFE solutions can enhance your application's reliability and efficiency.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance