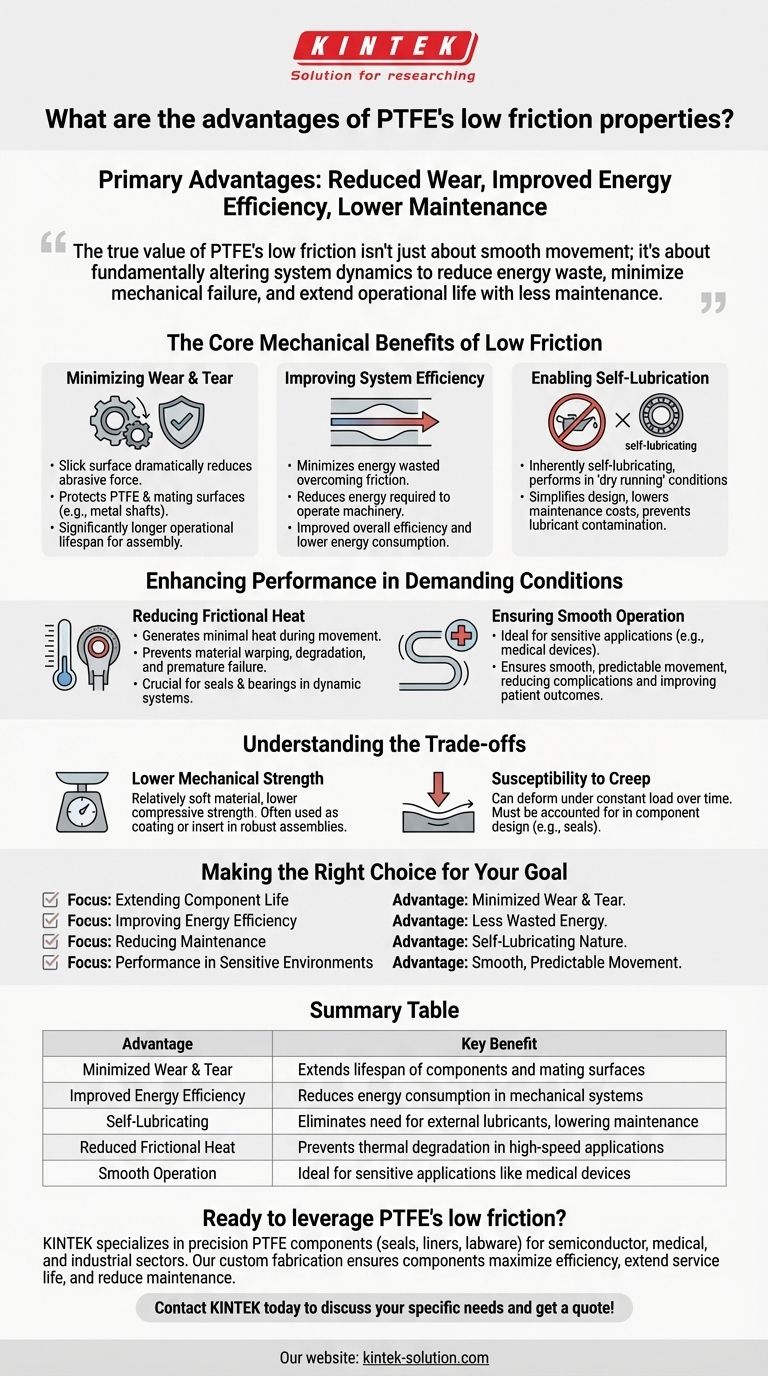

The primary advantages of PTFE's low friction are a significant reduction in wear and tear on components, improved energy efficiency in mechanical systems, and a lower need for maintenance. Its exceptionally low coefficient of friction allows surfaces to slide against each other with minimal resistance, directly extending the lifespan of parts like bearings, seals, and gears.

The true value of PTFE's low friction isn't just about smooth movement; it's about fundamentally altering system dynamics to reduce energy waste, minimize mechanical failure, and extend operational life with less maintenance.

The Core Mechanical Benefits of Low Friction

The unique molecular structure of Polytetrafluoroethylene (PTFE) gives it one of the lowest coefficients of friction of any known solid material. This property translates into several direct, tangible advantages in mechanical and industrial applications.

Minimizing Wear and Tear

When components rub against each other, friction is the primary cause of wear, degradation, and eventual failure.

PTFE's slick surface dramatically reduces this abrasive force. This protects not only the PTFE component itself but also the mating surfaces it contacts, such as metal shafts or housings. The result is a significantly longer operational lifespan for the entire assembly.

Improving System Efficiency

Friction is a form of resistance that requires energy to overcome. In any dynamic system, from automotive engines to manufacturing machinery, this translates to wasted energy.

By minimizing this resistance, PTFE reduces the energy required to operate the machinery. This leads to improved overall efficiency and lower energy consumption, which is a critical concern in many modern applications.

Enabling Self-Lubrication

Many mechanical systems require external lubricants like grease or oil to reduce friction, which adds complexity and maintenance requirements.

PTFE is inherently self-lubricating. Its low-friction nature allows it to perform exceptionally well without additional lubrication, even in "dry running" conditions. This simplifies design, lowers maintenance costs, and prevents contamination from lubricants.

Enhancing Performance in Demanding Conditions

Beyond the fundamental benefits, PTFE's low friction makes it a problem-solver in applications where other materials would fail.

Reducing Frictional Heat

In high-speed or high-load applications, friction can generate a significant amount of heat. This heat can cause materials to warp, degrade, or fail prematurely.

PTFE's ability to operate with minimal friction means it generates very little heat during movement. This thermal stability is crucial for seals and bearings in dynamic, high-performance systems.

Ensuring Smooth Operation in Sensitive Applications

In fields like medicine, the quality of movement is critical. Frictional resistance can cause patient discomfort or damage to sensitive tissues.

PTFE's non-stick, low-friction surface is ideal for medical devices like catheters. It ensures smooth, predictable movement, reducing complications and improving patient outcomes.

Understanding the Trade-offs

While its low friction is a powerful advantage, no material is perfect. A technical advisor must acknowledge the context in which PTFE operates and its inherent limitations.

Lower Mechanical Strength

Compared to metals and many other engineering plastics, PTFE is a relatively soft material. It has lower compressive strength and is not suitable for high-load structural applications on its own. It is often used as a coating or insert in a more robust assembly.

Susceptibility to Creep

Under a constant, sustained load, PTFE can slowly deform over time—a phenomenon known as creep. This must be accounted for in the design of components like seals and gaskets to ensure long-term performance.

Making the Right Choice for Your Goal

Selecting PTFE for its low friction depends entirely on your project's most critical objective.

- If your primary focus is extending component life: PTFE's ability to minimize wear on mating surfaces is its key advantage, preventing premature failure.

- If your primary focus is improving energy efficiency: Its extremely low coefficient of friction directly translates to less wasted energy in moving systems.

- If your primary focus is reducing maintenance: The self-lubricating nature of PTFE eliminates the need for external lubricants and their associated upkeep.

- If your primary focus is performance in a sensitive environment: PTFE provides the smooth, non-stick, and predictable movement required for medical or precision applications.

Ultimately, leveraging PTFE's low friction allows for the design of more robust, efficient, and reliable systems.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Minimized Wear & Tear | Extends lifespan of components and mating surfaces |

| Improved Energy Efficiency | Reduces energy consumption in mechanical systems |

| Self-Lubricating | Eliminates need for external lubricants, lowering maintenance |

| Reduced Frictional Heat | Prevents thermal degradation in high-speed applications |

| Smooth Operation | Ideal for sensitive applications like medical devices |

Ready to leverage PTFE's low friction for your application?

KINTEK specializes in manufacturing precision PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication, from prototypes to high-volume orders, ensures you get components that maximize efficiency, extend service life, and reduce maintenance.

Contact KINTEK today to discuss your specific needs and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability