The primary advantage of PTFE's impact resistance is its ability to ensure exceptional durability and longevity in components subjected to mechanical stress. This physical toughness allows parts made from Polytetrafluoroethylene (PTFE) to withstand sudden, forceful interactions without fracturing, making it a highly reliable material for demanding operational environments.

While its physical toughness is significant, PTFE's true value emerges from its unique combination of impact resistance, near-total chemical inertness, and broad environmental stability, making it a premier material for components that must survive multifaceted, harsh conditions.

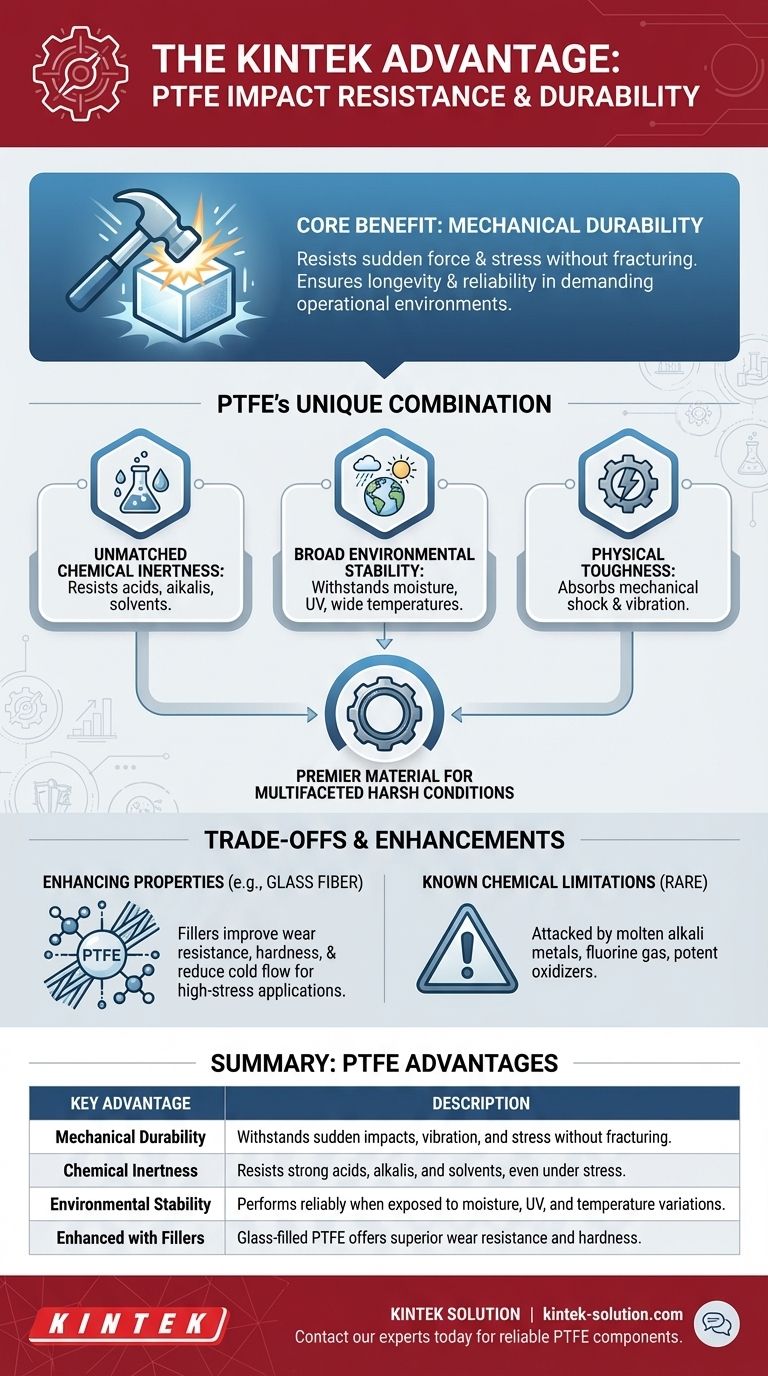

The Core Benefit: Mechanical Durability

PTFE is not just chemically resilient; it is physically robust. This combination is central to its value in industrial and engineering applications where failure is not an option.

Resisting Sudden Force and Stress

PTFE's molecular structure allows it to absorb and dissipate energy from sudden impacts. This prevents cracking and catastrophic failure in parts that experience mechanical shock.

This property is crucial for components like seals, gaskets, and impellers that are subject to constant vibration, pressure changes, or direct forceful contact during operation.

Ensuring Longevity and Reliability

By resisting physical damage, PTFE components last longer, reducing the frequency of replacements and associated downtime.

This inherent durability translates directly into lower maintenance overhead and more predictable, reliable system performance over the long term.

Why Impact Resistance is Only Part of the Story

Evaluating PTFE solely on its impact strength overlooks the key attributes that make it such a powerful engineering solution. Its true strength lies in its ability to resist multiple forms of degradation simultaneously.

Unmatched Chemical Inertness

PTFE is famously inert and non-reactive with the vast majority of industrial chemicals. It is highly resistant to strong acids, alkalis, solvents, and other corrosive media.

This makes it an ideal choice for pipelines, valve components, and pump impellers that must handle aggressive substances while also enduring the physical stresses of fluid flow and pressure.

Broad Environmental Stability

Beyond chemical exposure, PTFE stands up exceptionally well to environmental factors. It is highly resistant to degradation from moisture and UV radiation.

This stability makes it suitable for outdoor applications and in industrial settings where components are exposed to a wide range of environmental conditions.

Understanding the Trade-offs and Enhancements

While standard PTFE is impressive, its properties can be tailored, and it's important to understand its limitations to specify it correctly.

The Role of Fillers like Glass Fiber

To enhance its mechanical properties, PTFE is often blended with fillers. Adding glass fiber significantly improves wear resistance, hardness, and resistance to "cold flow" (deformation under load).

This allows for the creation of PTFE composites that retain chemical inertness while offering superior performance in high-wear, high-stress mechanical applications.

Known Chemical Limitations

Despite its broad resistance, PTFE is not invincible. It can be attacked by a few highly reactive substances, such as molten or dissolved alkali metals, fluorine gas, and other extremely potent oxidizers.

Understanding these specific limitations is critical for ensuring material compatibility in niche, highly aggressive chemical applications.

Making the Right Choice for Your Application

Selecting the right material depends on a clear understanding of your primary operational challenge.

- If your primary focus is mechanical stress and impact: PTFE is an excellent choice, and a glass-filled variant should be considered for applications requiring additional hardness and wear resistance.

- If your primary focus is extreme chemical exposure: PTFE's near-total chemical inertness makes it one of the most reliable materials available for containing or processing corrosive substances.

- If your primary focus is a combination of impact, chemical, and environmental stress: PTFE is an ideal solution, as its ability to withstand all these challenges at once is its defining advantage.

Ultimately, PTFE's combination of physical toughness and chemical stability makes it a uniquely versatile problem-solver for the most demanding engineering challenges.

Summary Table:

| Key Advantage | Description |

|---|---|

| Mechanical Durability | Withstands sudden impacts, vibration, and stress without fracturing. |

| Chemical Inertness | Resists strong acids, alkalis, and solvents, even under stress. |

| Environmental Stability | Performs reliably when exposed to moisture, UV, and temperature variations. |

| Enhanced with Fillers | Glass-filled PTFE offers superior wear resistance and hardness. |

Need a component that can survive impact, chemicals, and harsh environments?

At KINTEK, we specialize in manufacturing high-performance PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Our precision production and custom fabrication services, from prototypes to high-volume orders, ensure you get durable, reliable parts that reduce downtime and maintenance costs.

Contact our experts today to discuss how our PTFE solutions can solve your most demanding application challenges.

Visual Guide

Related Products

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What are the primary applications of Teflon? Leverage Its Unique Properties for Your Industry

- What are the unique properties of PTFE that make it commercially valuable? Unlock Unmatched Performance

- Why is chemical compatibility important when choosing a PTFE-coated septum? Avoid Sample Contamination and Data Loss

- What are some exceptional properties of PTFE? Unlock Unmatched Performance in Extreme Environments

- What makes the PTFE bottle durable? Unmatched Chemical & Thermal Stability for Demanding Applications