The primary advantage of PTFE's chemical resistance is its ability to maintain seal integrity in the presence of aggressive media that would cause other materials to degrade, swell, or fail. This chemical inertness prevents leaks, reduces maintenance, and ensures operational safety in demanding environments like chemical processing, where exposure to strong acids, bases, and organic solvents is constant.

While often cited for many properties, PTFE's near-total chemical inertness is the foundational characteristic for sealing. This single feature ensures that its other beneficial properties—like temperature stability and low friction—are not compromised, resulting in an exceptionally reliable and long-lasting seal.

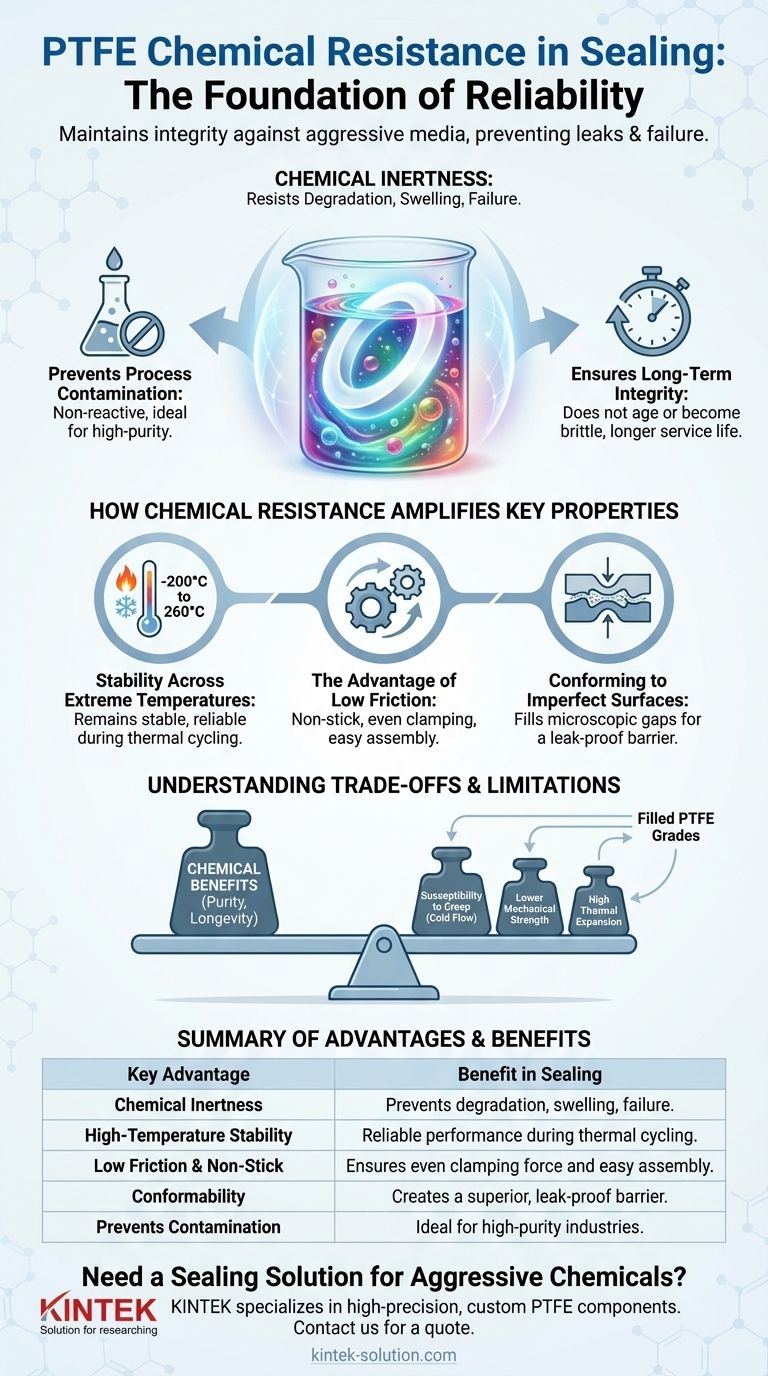

The Foundation of Reliability: Unpacking Chemical Inertness

The term "chemical resistance" refers to a material's ability to resist degradation from chemical attack. For Polytetrafluoroethylene (PTFE), this resistance is exceptionally high, making it virtually inert.

Resisting Aggressive Media

PTFE is unaffected by almost all industrial chemicals, including concentrated acids, alkalis, and organic solvents.

Unlike other polymers that might swell, soften, or dissolve, PTFE maintains its structural and dimensional integrity. This prevents the seal from weakening or changing shape, which would otherwise lead to failure.

Preventing Process Contamination

Because PTFE is so inert, it does not react with or leach substances into the media it is sealing.

This is a critical advantage in high-purity applications such as pharmaceuticals, food and beverage, and semiconductor manufacturing, where even trace amounts of contamination can ruin a product batch.

Ensuring Long-Term Seal Integrity

The longevity of a seal is directly tied to the material's stability. A seal made from a material that slowly degrades will inevitably fail.

PTFE's resistance to chemical attack means it does not age or become brittle due to chemical exposure, leading to a significantly longer service life and more predictable performance.

How Chemical Resistance Amplifies Other Key Properties

PTFE's true value in sealing comes from how its chemical inertness works in concert with its other unique physical properties. This combination creates a material that performs reliably where others cannot.

Stability Across Extreme Temperatures

PTFE maintains its properties across an exceptionally wide temperature range, typically from -200°C to 260°C (-328°F to 500°F).

Crucially, its chemical resistance is not diminished at these temperature extremes. Other materials may become more susceptible to chemical attack when heated, but PTFE remains stable, ensuring a reliable seal during temperature fluctuations.

The Advantage of Low Friction

PTFE has one of the lowest coefficients of friction of any solid material. This non-stick, low-friction surface complements its chemical resistance perfectly.

When a joint is tightened, a PTFE gasket allows mating surfaces to slide easily without galling or tearing the seal. This ensures the clamping force is distributed evenly to create a tight seal, a process that is not hindered by chemical reactions that could cause surfaces to stick.

Conforming to Imperfect Surfaces

PTFE is a relatively soft material that deforms under pressure to fill microscopic imperfections between two mating surfaces, which is essential for creating a leak-proof barrier.

Its chemical inertness guarantees that this softness is not compromised over time. The material won't harden or become brittle from chemical exposure, allowing it to maintain its conformability and effective sealing capability.

Understanding the Trade-offs and Limitations

No material is perfect, and a complete technical understanding requires acknowledging a material's limitations. While its chemical properties are superior, its mechanical properties present trade-offs.

Susceptibility to Creep (Cold Flow)

PTFE has a tendency to deform permanently under sustained pressure, a phenomenon known as creep or cold flow. In sealing applications, this can lead to a loss of bolt torque and potential leaks over time, especially in high-pressure or cycling temperature conditions.

Lower Mechanical Strength

Compared to metals or even other high-performance plastics, PTFE has lower tensile strength and abrasion resistance. It is not suitable for dynamic sealing applications where it would be subject to significant friction or wear.

High Thermal Expansion

PTFE expands and contracts with temperature changes more than the metal flanges it typically seals. This high coefficient of thermal expansion must be accounted for in the joint design to maintain seal pressure across the operating temperature range.

Making the Right Choice for Your Application

Selecting the right sealing material requires balancing chemical compatibility with the mechanical and thermal demands of the system.

- If your primary focus is sealing against highly corrosive chemicals: PTFE's inertness is unparalleled, making it the default choice for maximizing reliability and safety.

- If your application involves high pressure and temperature cycling: Consider filled PTFE grades (e.g., glass- or carbon-filled) to significantly reduce creep and better manage thermal expansion.

- If your priority is preventing media contamination: Virgin PTFE's non-leaching and inert nature provides the ultimate assurance of product purity.

By understanding how PTFE's elite chemical resistance underpins its other physical traits, you can confidently specify a sealing solution that delivers unmatched performance in the most demanding environments.

Summary Table:

| Key Advantage | Description | Benefit in Sealing |

|---|---|---|

| Chemical Inertness | Resists virtually all acids, bases, and solvents. | Prevents degradation, swelling, and failure. |

| High-Temperature Stability | Maintains properties from -200°C to 260°C. | Reliable performance during thermal cycling. |

| Low Friction & Non-Stick | One of the lowest coefficients of friction. | Ensures even clamping force and easy assembly. |

| Conformability | Deforms to fill surface imperfections. | Creates a superior, leak-proof barrier. |

| Prevents Contamination | Non-reactive and non-leaching. | Ideal for high-purity industries like pharma and semiconductors. |

Need a Sealing Solution for Aggressive Chemicals?

Leverage PTFE's superior chemical resistance to protect your critical processes. KINTEK specializes in manufacturing high-precision, custom PTFE components—including seals, gaskets, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors.

We ensure reliability and longevity by prioritizing precision production and offering custom fabrication from prototypes to high-volume orders.

Contact us today to discuss your specific application requirements and receive a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance