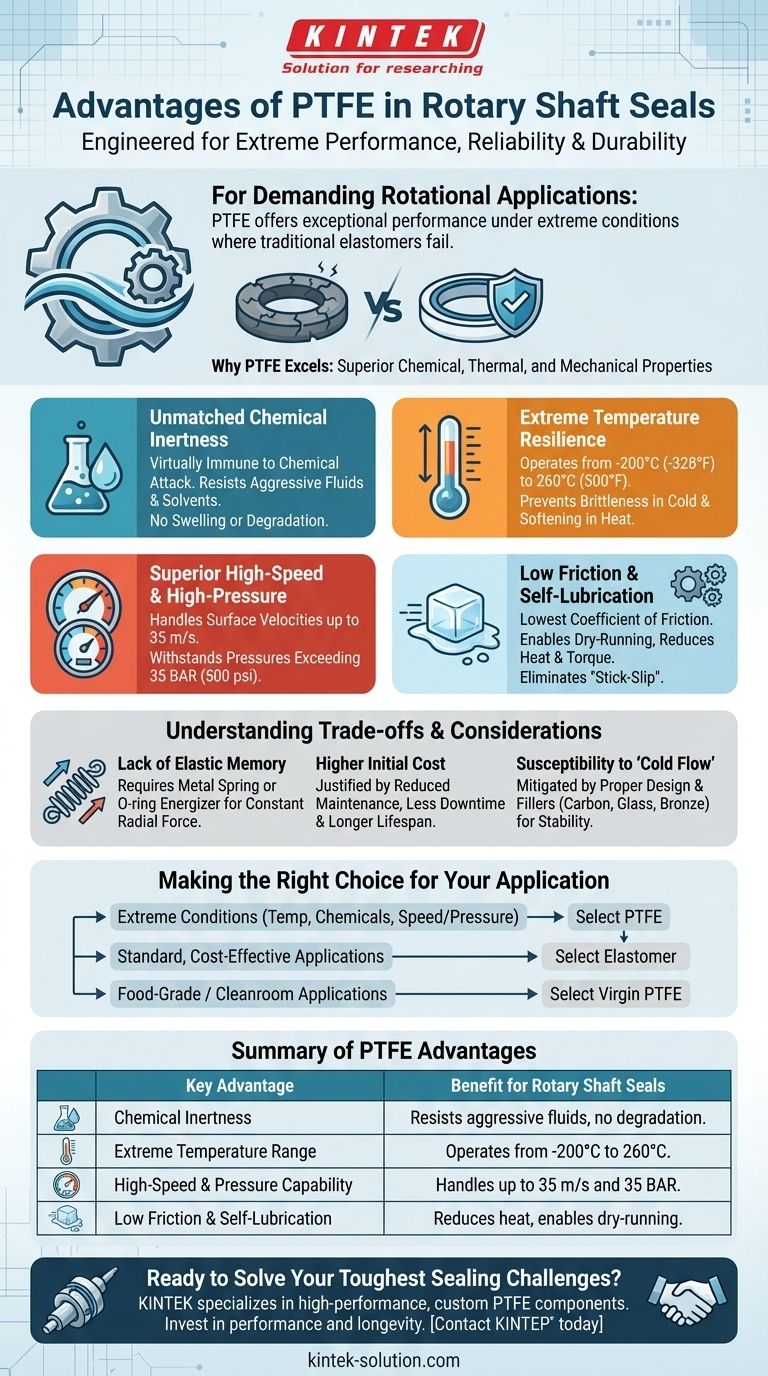

For demanding rotational applications, the primary advantages of Polytetrafluoroethylene (PTFE) are its exceptional performance under extreme conditions. PTFE rotary shaft seals can operate at higher pressures and speeds, withstand a vastly wider range of temperatures, and remain inert to aggressive chemicals and lubricants that would degrade traditional elastomer seals. This combination of properties results in a more durable and reliable seal with a significantly longer service life in challenging environments.

While traditional elastomer seals are effective for general use, PTFE seals are engineered for extremes. Their core advantage lies in a unique combination of chemical, thermal, and mechanical properties that solve sealing challenges where conventional materials would fail.

Why PTFE Excels Where Elastomers Fall Short

The decision to use a PTFE seal often comes when the operational limits of a standard rubber seal are reached. PTFE's molecular structure gives it a set of inherent advantages for high-performance machinery.

Unmatched Chemical Inertness

PTFE is one of the most non-reactive substances known, making it virtually immune to chemical attack. This is critical in applications involving aggressive fluids, solvents, or a wide variety of lubricants.

Unlike elastomers that can swell, harden, or degrade upon exposure, PTFE maintains its integrity, ensuring a consistent and reliable seal.

Extreme Temperature Resilience

PTFE seals operate effectively across an exceptionally broad temperature spectrum, from cryogenic lows around -200°C (-328°F) to continuous highs of 260°C (500°F).

This stability prevents the material from becoming brittle in the cold or soft at high temperatures, a common failure point for many rubber compounds.

Superior High-Speed and High-Pressure Capability

The material's rigidity and low friction allow it to handle conditions that would destroy an elastomer seal. PTFE seals can reliably manage surface velocities up to 35 m/s and pressures exceeding 35 BAR (500 psi).

This makes them the definitive choice for high-RPM shafts and hydraulic systems where dynamic pressure is a constant factor.

Inherently Low Friction and Self-Lubrication

PTFE has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice. This results in several key operational benefits.

It allows for dry-running capability in certain applications, generates significantly less heat, reduces torque requirements, and eliminates "stick-slip" behavior during startup, ensuring smooth operation.

Understanding the Trade-offs and Considerations

While PTFE offers superior performance in many areas, it is not a universal replacement for elastomer seals. Acknowledging its unique properties and design requirements is crucial for successful implementation.

Lack of Elastic Memory

Unlike rubber, PTFE is not a true elastomer and has very poor elastic memory. It will not spring back to its original shape if deformed.

Because of this, most PTFE seal designs incorporate a metallic spring or an O-ring energizer to provide the constant radial force needed to maintain a tight seal against the shaft.

Higher Initial Cost

The advanced polymer and often more complex manufacturing processes mean that PTFE seals typically have a higher upfront cost than standard nitrile or viton seals.

However, this cost is frequently justified by reduced maintenance, less downtime, and a longer operational lifespan, leading to a lower total cost of ownership.

Susceptibility to "Cold Flow"

PTFE can be subject to creep, or "cold flow," where the material slowly deforms under a constant load over time.

Proper seal design and the use of fillers (like carbon, glass, or bronze) in the PTFE compound are critical to mitigate this effect and ensure long-term dimensional stability.

Making the Right Choice for Your Application

Selecting the correct seal material is a foundational engineering decision that directly impacts equipment performance and reliability. Your choice should be guided by the specific demands of the operating environment.

- If your primary focus is reliability in extreme conditions: PTFE is the clear choice for applications with high temperatures, aggressive chemicals, or high speeds and pressures.

- If your primary focus is a standard, cost-effective application: A traditional elastomer seal is often sufficient for moderate temperatures, common lubricants, and lower speeds.

- If your primary focus is food-grade or cleanroom applications: Virgin PTFE's inertness and FDA approval, combined with its low outgassing properties, make it an ideal solution.

Ultimately, choosing PTFE is an investment in durability and performance for the most critical components of your equipment.

Summary Table:

| Key Advantage | Benefit for Rotary Shaft Seals |

|---|---|

| Chemical Inertness | Resists aggressive fluids and lubricants that degrade elastomers. |

| Extreme Temperature Range | Operates from -200°C to 260°C (-328°F to 500°F). |

| High-Speed & Pressure Capability | Handles surface speeds up to 35 m/s and pressures exceeding 35 BAR. |

| Low Friction & Self-Lubrication | Reduces heat, torque, and enables dry-running in some applications. |

Ready to Solve Your Toughest Sealing Challenges?

For demanding applications in the semiconductor, medical, laboratory, and industrial sectors, off-the-shelf seals often fall short. KINTEK specializes in manufacturing high-performance, precision PTFE components—including custom rotary shaft seals—that are engineered to thrive in extreme conditions.

We partner with you from prototype to high-volume production to deliver seals that offer:

- Unmatched Reliability: Ensure continuous operation under high temperatures, pressures, and chemical exposure.

- Longer Service Life: Reduce downtime and maintenance costs with components built for durability.

- Custom Solutions: Get a seal perfectly tailored to your specific operational requirements and environment.

Invest in performance and longevity. Contact KINTEPT today to discuss your custom PTFE sealing solution.

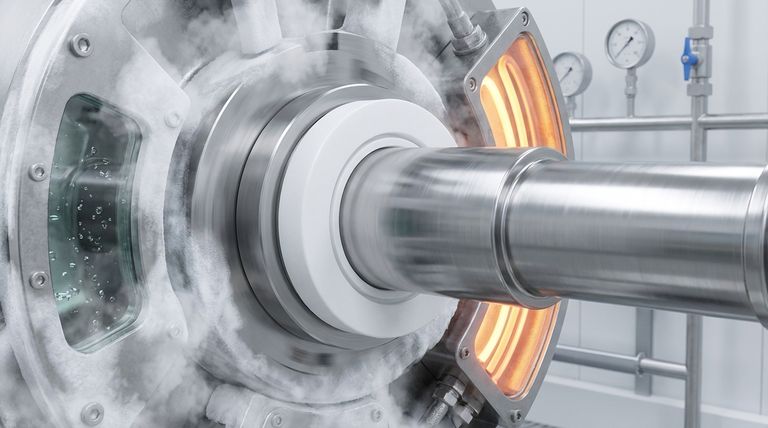

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications