The primary advantages of machining Polytetrafluoroethylene (PTFE) are its unique combination of extreme durability and inherent machinability. This allows for the creation of highly precise, complex components that can withstand harsh chemical, thermal, and electrical environments where most other materials would fail. Its exceptionally low friction and non-stick surface make it a premier choice for dynamic applications like seals, bearings, and insulators.

The decision to machine PTFE is not just about its final properties, but about the ability to achieve tight tolerances on a material that is uniquely resilient. Success, however, hinges on understanding that its softness and thermal expansion are not flaws, but critical process variables that must be expertly managed.

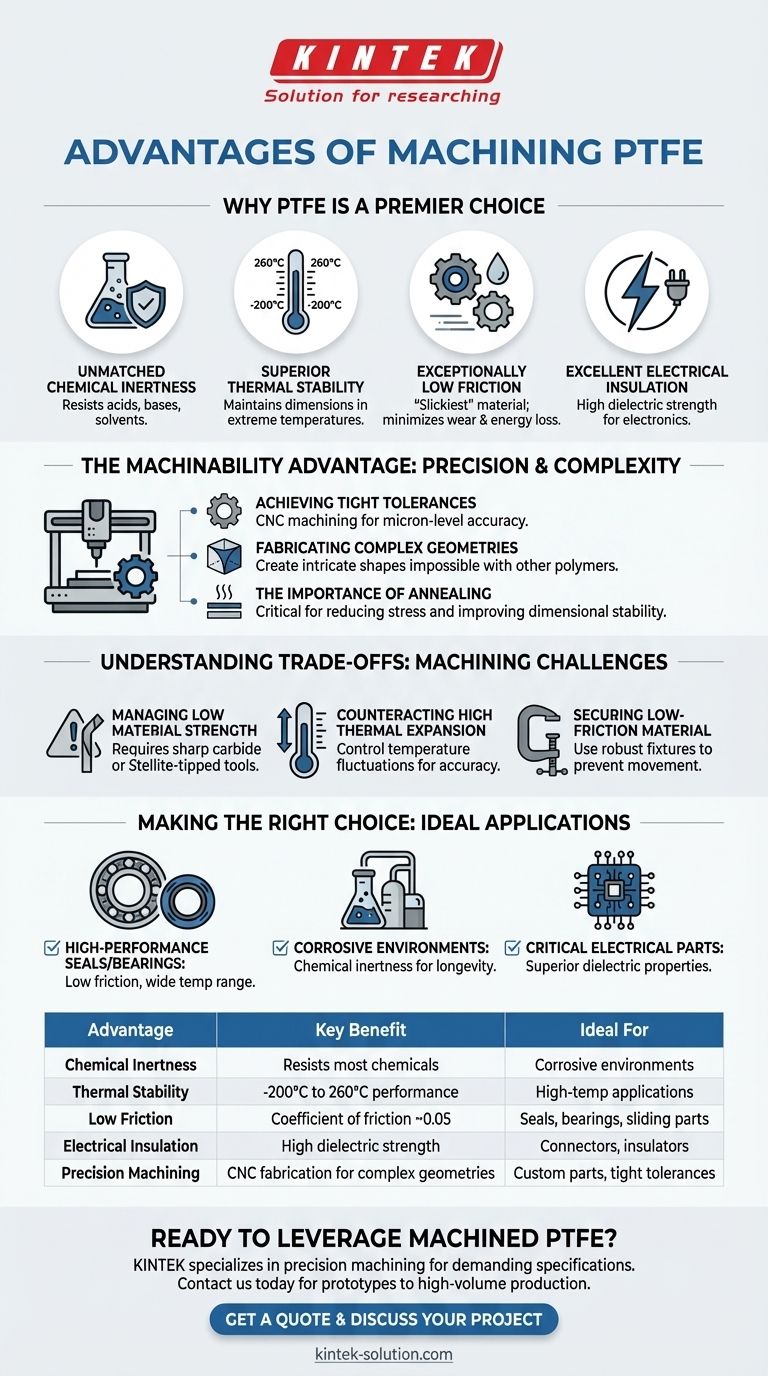

Why PTFE is a Premier Choice for Machined Components

PTFE's value proposition comes from a set of inherent material properties that make it uniquely suited for specialized and demanding industrial parts.

Unmatched Chemical Inertness

PTFE offers exceptionally high chemical resistance. This makes it an ideal material for components used in corrosive environments, as it will not degrade when exposed to most acids, bases, and solvents.

Superior Thermal Stability

The material demonstrates remarkable dimensional stability across a vast temperature range, from -328°F to 500°F (-200°C to 260°C). This ensures that machined parts maintain their critical dimensions and performance even under extreme thermal cycling.

Exceptionally Low Friction

With a coefficient of friction between 0.05 and 0.20, PTFE is one of the "slickiest" solid materials known. This property is invaluable for manufacturing sliding or rotating parts, such as bearings and seals, where minimizing wear and energy loss is critical.

Excellent Electrical Insulation

PTFE is a superb electrical insulator with high dielectric strength. This makes it a go-to material for connectors, insulators, and other components in the aerospace and electronics industries.

The Machinability Advantage: Precision and Complexity

While PTFE is a soft material, modern machining techniques allow for the fabrication of incredibly intricate and precise parts that leverage its unique properties.

Achieving Tight Tolerances

Using CNC machining allows for the precise fabrication of PTFE components with micron-level accuracy. This process is essential for overcoming the material's softness and ensuring consistent, repeatable results for critical applications.

Fabricating Complex Geometries

The combination of PTFE's properties and CNC precision makes it possible to create complex shapes that would be difficult or impossible with other high-performance polymers. This is crucial for custom-designed industrial parts.

The Importance of Annealing

For applications requiring the tightest tolerances, annealing the PTFE before or after machining is a critical step. This process reduces internal stresses, minimizes the risk of surface cracks, and improves overall dimensional stability, preventing premature part failure.

Understanding the Trade-offs: Key Machining Challenges

The same properties that make PTFE advantageous also present specific challenges during the machining process. Acknowledging these trade-offs is key to a successful outcome.

Managing Low Material Strength

PTFE's softness means that standard tooling can cause deformation or a poor surface finish. The ideal setup uses extremely sharp Stellite-tipped or carbide tools with a positive top rake to reduce cutting forces and ensure a clean cut.

Counteracting High Thermal Expansion

PTFE has a high coefficient of thermal expansion, meaning it can change size significantly with temperature fluctuations during machining. This must be anticipated and controlled to maintain narrow tolerance ranges.

Securing Low-Friction Material

The material's low friction makes it difficult to hold securely. Machining requires robust fixtures that tightly grip the workpiece to prevent any movement that could compromise accuracy.

Making the Right Choice for Your Application

Selecting PTFE is a strategic decision based on performance requirements. The key is to align the material's strengths with your primary engineering goal.

- If your primary focus is high-performance seals or bearings: Leverage PTFE's extremely low friction and wide temperature range for maximum durability and efficiency.

- If your primary focus is components for corrosive environments: Capitalize on its chemical inertness to ensure part longevity in harsh processing or chemical industries.

- If your primary focus is critical electrical parts: Rely on its superior dielectric properties and dimensional stability to create reliable insulators and connectors.

Ultimately, choosing to machine PTFE is an investment in unparalleled performance, provided you respect the specific handling and processing it demands.

Summary Table:

| Advantage | Key Benefit | Ideal For |

|---|---|---|

| Chemical Inertness | Resists most acids, bases, and solvents | Corrosive environments, chemical processing |

| Thermal Stability | Performs from -200°C to 260°C | High-temperature applications, thermal cycling |

| Low Friction | Coefficient of friction as low as 0.05 | Seals, bearings, sliding parts |

| Electrical Insulation | High dielectric strength | Connectors, insulators, aerospace components |

| Precision Machining | CNC fabrication for complex geometries | Custom parts with tight tolerances |

Ready to Leverage the Advantages of Machined PTFE for Your Application?

At KINTEK, we specialize in the precision machining of high-performance PTFE components. Our expertise in managing the unique properties of PTFE—from its softness to its thermal expansion—ensures you receive parts that meet the most demanding specifications for durability, chemical resistance, and performance.

We manufacture critical PTFE components like seals, liners, bearings, and custom labware for the semiconductor, medical, laboratory, and industrial sectors. Whether you need prototypes or high-volume production, our custom fabrication process is designed to deliver reliability and precision.

Contact us today to discuss your project requirements and discover how our PTFE machining capabilities can provide the solution you need.

Get a Quote & Discuss Your Project

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs