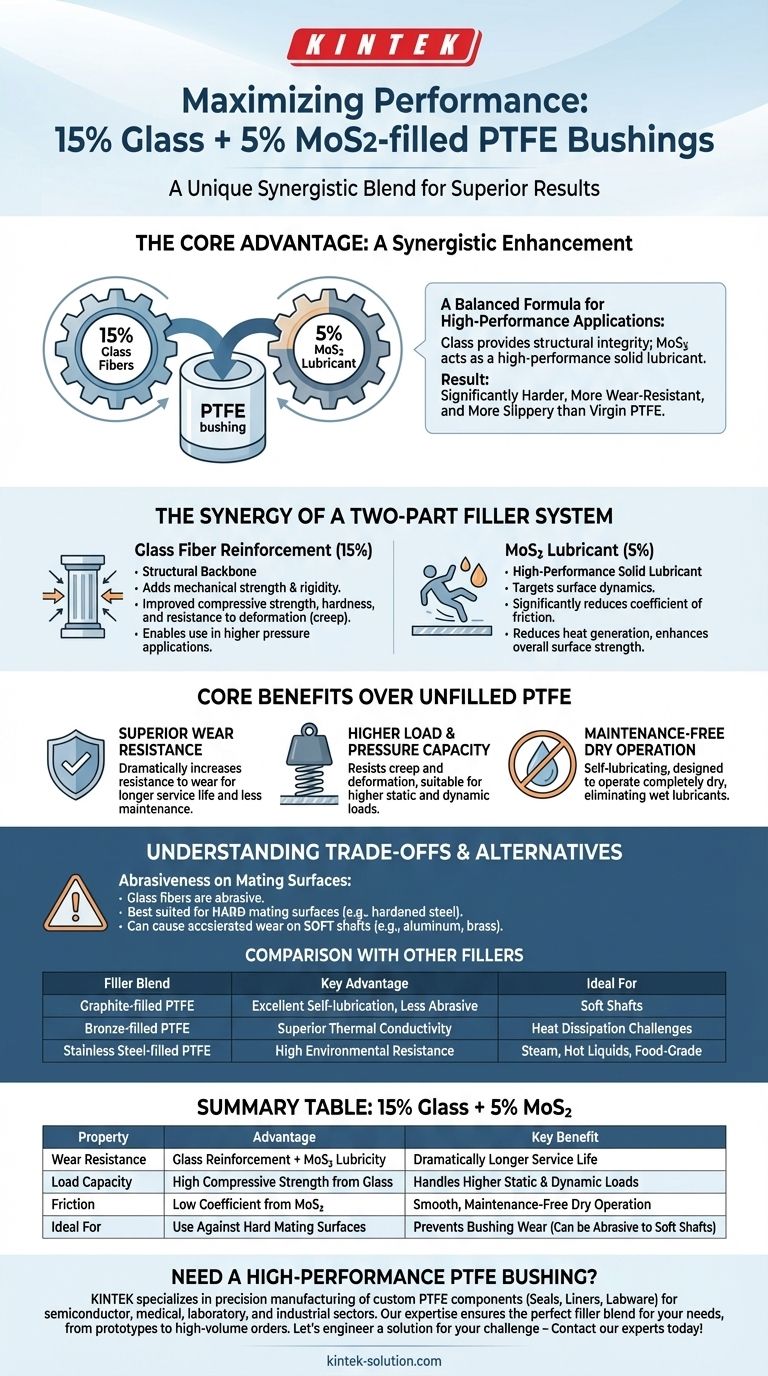

The primary advantage of 15% Glass + 5% MoS2-filled PTFE bushings is a unique, synergistic enhancement of PTFE's natural properties. This specific blend creates a material that is significantly harder, more resistant to compression and wear, and even more slippery than virgin PTFE. The glass provides structural integrity, while the Molybdenum Disulfide (MoS2) acts as a high-performance solid lubricant.

The core takeaway is that this isn't just a random mixture; it's a balanced formula for high-performance applications. The glass fibers act as a reinforcement against physical forces, while the MoS2 minimizes the frictional forces that cause wear, creating a component that is both tough and smooth-operating.

The Synergy of a Two-Part Filler System

The effectiveness of this material comes from how the two distinct fillers complement each other to overcome the limitations of unfilled PTFE.

The Role of Glass Fiber Reinforcement (15%)

Glass fibers serve as the structural backbone of the composite. Their primary function is to add mechanical strength and rigidity.

By integrating glass, the bushing gains improved compressive strength and hardness. This makes it far more resistant to deformation, or "creep," under sustained loads.

This reinforcement allows the material to be used in higher pressure applications where virgin PTFE would fail.

The Role of MoS2 Lubricant (5%)

Molybdenum Disulfide (MoS2) is a well-known solid lubricant. Its inclusion directly targets the component's surface dynamics.

MoS2 significantly reduces the coefficient of friction, making the material more slippery than even standard PTFE.

This enhanced lubricity reduces heat generation during operation, especially at high sliding velocities, and enhances overall surface strength.

Core Benefits Over Unfilled PTFE

Adding these fillers elevates the material from a general-purpose plastic to a specialized engineering component.

Superior Wear Resistance

The combination of a harder base material (from the glass) and a lower-friction surface (from the MoS2) dramatically increases resistance to wear.

This directly translates to a longer service life for the bushing and less frequent maintenance cycles.

Higher Load and Pressure Capacity

Because the glass fibers resist creep and deformation, these bushings can handle much higher static and dynamic loads.

This makes them suitable for demanding mechanical systems where consistent dimensional stability is critical.

Maintenance-Free Dry Operation

Like all PTFE-based materials, these bushings are self-lubricating and designed to operate completely dry.

This eliminates the cost and complexity of external lubrication systems and prevents the contamination associated with wet lubricants.

Understanding the Trade-offs and Alternatives

While highly effective, this blend is not a universal solution. Understanding its limitations is key to proper application.

Abrasiveness on Mating Surfaces

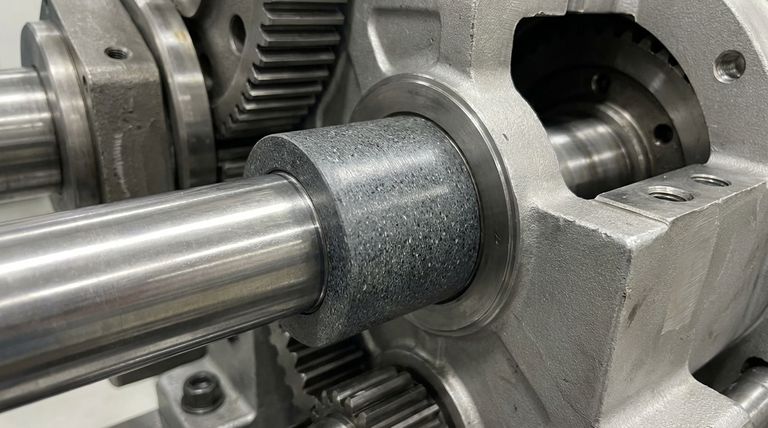

A critical consideration is that glass fibers are abrasive. This blend is best suited for use against very hard mating surfaces, such as hardened steel shafts.

Using a glass-filled bushing against a soft shaft material like aluminum or brass can cause accelerated wear on the shaft itself.

Comparison with Other Fillers

Different fillers are chosen to solve different problems. This blend is just one of many options available.

- Graphite-filled PTFE offers excellent self-lubrication and is less abrasive, making it a better choice for soft shafts.

- Bronze-filled PTFE provides superior thermal conductivity, making it ideal for applications where dissipating heat is the primary challenge.

- Stainless Steel-filled PTFE is often used in applications involving steam or hot liquids, or in food-grade environments.

Making the Right Choice for Your Application

Selecting the correct bushing material requires matching the filler's properties to the specific demands of your system.

- If your primary focus is high loads and wear resistance against a hard shaft: The 15% Glass + 5% MoS2 blend is an excellent choice for its balance of strength and lubricity.

- If your primary focus is heat dissipation: Consider a bronze-filled PTFE bushing for its superior thermal conductivity.

- If you are using a soft mating surface (like aluminum): A graphite-filled or other non-abrasive filled PTFE is a more suitable option to prevent shaft wear.

- If your application involves steam or specific chemical environments: Look into stainless steel-filled PTFE for its targeted environmental resistance.

Choosing the right filler transforms a standard PTFE bushing into a precision-engineered component for your specific challenge.

Summary Table:

| Property | Advantage | Key Benefit |

|---|---|---|

| Wear Resistance | Glass reinforcement + MoS2 lubricity | Dramatically longer service life |

| Load Capacity | High compressive strength from glass fibers | Handles higher static & dynamic loads |

| Friction | Low coefficient from MoS2 | Smooth, maintenance-free dry operation |

| Ideal For | Use against hard mating surfaces (e.g., hardened steel) | Prevents bushing wear but can be abrasive to soft shafts |

Need a high-performance PTFE bushing for your demanding application?

At KINTEK, we specialize in precision manufacturing of custom PTFE components, including seals, liners, and labware for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in material science ensures you get the perfect filler blend—like the 15% Glass + 5% MoS2 composite—for superior wear resistance, load capacity, and longevity.

We handle everything from prototypes to high-volume orders, delivering components that meet your exact specifications. Let's engineer a solution for your specific challenge—contact our experts today for a consultation!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Customizable PTFE Three Neck Flasks for Advanced Chemical Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials