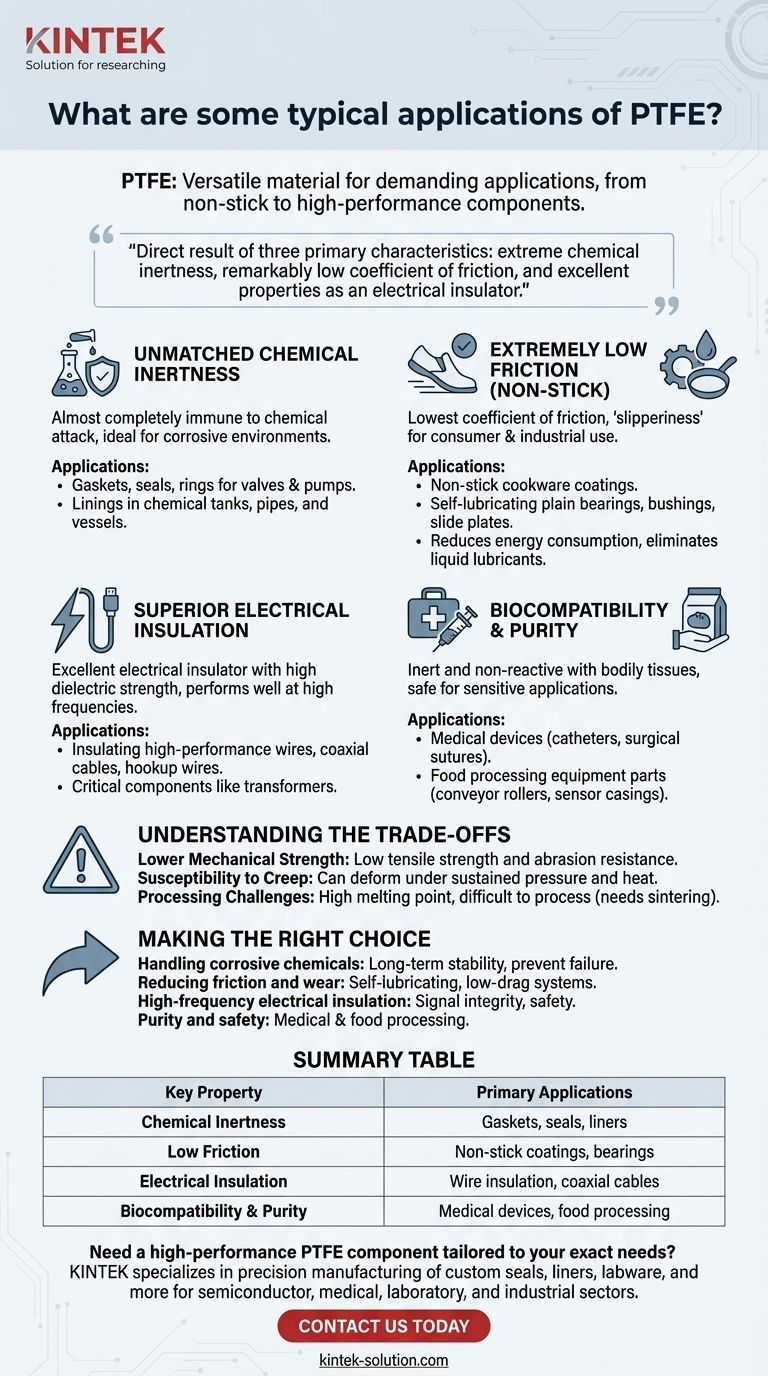

At its core, Polytetrafluoroethylene (PTFE) is used in an exceptionally wide range of applications, from non-stick cookware and electrical wire insulation to high-performance industrial components. Its most common uses include creating gaskets, seals, bearings, and linings for equipment handling corrosive chemicals, as well as specialized roles in the medical, aerospace, and food production industries.

The versatility of PTFE is not accidental. Its vast applications are a direct result of three primary characteristics: its extreme chemical inertness, its remarkably low coefficient of friction, and its excellent properties as an electrical insulator.

The Core Properties Driving PTFE's Versatility

To understand where PTFE is used, you must first understand what makes it unique. Its applications are not random; they are specific solutions that leverage its fundamental material properties.

Unmatched Chemical Inertness

PTFE is almost completely immune to chemical attack. This non-reactive nature makes it the material of choice for environments involving corrosive or reactive substances.

This property is critical for industrial applications. It is used to create gaskets, seals, and rings for valves and pumps that must contain aggressive fluids without degrading.

For larger-scale protection, PTFE is used for linings in chemical tanks, pipes, and vessels. This protects the structural material (often steel) from corrosion, extending the equipment's lifespan significantly.

Extremely Low Friction (Non-Stick)

PTFE has one of the lowest coefficients of friction of any solid material, which is why most people know it by its brand name, Teflon®. This "slipperiness" is invaluable in both consumer and industrial settings.

The most famous application is the non-stick coating on cookware. This same property is used to create high-performance, self-lubricating plain bearings, bushings, and slide plates for machinery.

In these mechanical applications, PTFE reduces energy consumption and eliminates the need for liquid lubricants, which is crucial in clean environments like food processing or in high-load, slow-moving equipment.

Superior Electrical Insulation

PTFE is an excellent electrical insulator with a high dielectric strength, meaning it can withstand a strong electric field without breaking down. It also performs well at high frequencies.

These properties make it ideal for insulating high-performance wires and cables, especially in demanding computer and aerospace applications like coaxial cables and hookup wires.

It is also used to insulate critical components like transformers, where electrical integrity and reliability are paramount.

Biocompatibility and Purity

Because it is so inert, PTFE is also biocompatible, meaning it does not react with bodily tissues or fluids. This makes it safe for use in sensitive applications.

In the medical field, it is used for devices like catheters, surgical sutures, and components for syringes.

Within the food and drink industry, its purity and non-stick surface are leveraged for parts like conveyor belt rollers and casings for temperature sensors that come into direct contact with products.

Understanding the Trade-offs

While its properties are exceptional, PTFE is not the solution for every problem. Understanding its limitations is key to using it effectively.

Lower Mechanical Strength

Compared to metals and many other engineering plastics, PTFE has relatively low tensile strength and abrasion resistance. It is not a suitable material for high-load structural components on its own.

Susceptibility to Creep

PTFE is known for "creep" or cold flow. Under sustained pressure, especially at elevated temperatures, the material can slowly deform. This must be accounted for in the design of components like gaskets and seals.

Processing Challenges

PTFE has a very high melting point and melt viscosity, making it difficult to process using conventional methods like injection molding. It typically requires specialized techniques like compression molding and sintering.

Making the Right Choice for Your Goal

To apply this knowledge, match your primary engineering challenge to PTFE's core strengths.

- If your primary focus is handling corrosive chemicals: Use PTFE for gaskets, seals, and linings to ensure long-term stability and prevent equipment failure.

- If your primary focus is reducing friction and wear: Employ PTFE in bearings, bushings, or as a surface coating to create self-lubricating, low-drag systems.

- If your primary focus is high-frequency electrical insulation: Choose PTFE for critical wiring and cable applications where signal integrity and safety are essential.

- If your primary focus is purity and safety: It is an excellent choice for components in medical devices or food processing equipment due to its inert and non-toxic nature.

Ultimately, PTFE's value comes from leveraging its unique combination of properties to solve problems that other materials simply cannot.

Summary Table:

| Key Property | Primary Applications |

|---|---|

| Chemical Inertness | Gaskets, seals, liners for chemical tanks and pipes |

| Low Friction | Non-stick coatings, self-lubricating bearings, bushings |

| Electrical Insulation | High-performance wire insulation, coaxial cables, transformers |

| Biocompatibility & Purity | Medical devices (catheters, sutures), food processing equipment |

Need a high-performance PTFE component tailored to your exact needs?

KINTEK specializes in the precision manufacturing of PTFE components—including custom seals, liners, labware, and more—for the semiconductor, medical, laboratory, and industrial sectors. Whether you require a prototype or a high-volume production run, we deliver the chemical resistance, low friction, and purity your application demands.

Contact us today to discuss your project and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the key features of PTFE laminated fabric? Unmatched Protection & Breathability

- How long does Teflon coating typically last on cookware? Maximize Your Pan's Lifespan

- What is the scientific name for Teflon and what type of material is it? A Guide to PTFE

- What is the tensile strength range of PTFE? Understanding Its Mechanical Limits for Your Design

- What is PTFE, and why are alternatives being sought? Navigating the Shift from 'Forever Chemicals'

- What are the key properties of PTFE relevant to troubleshooting and maintenance? Master PTFE's Strengths and Weaknesses

- What are the key structural components of Teflon? Unlocking the Secrets of PTFE's Performance

- What is modified PTFE and how does it differ from standard PTFE? A Guide to Enhanced Performance