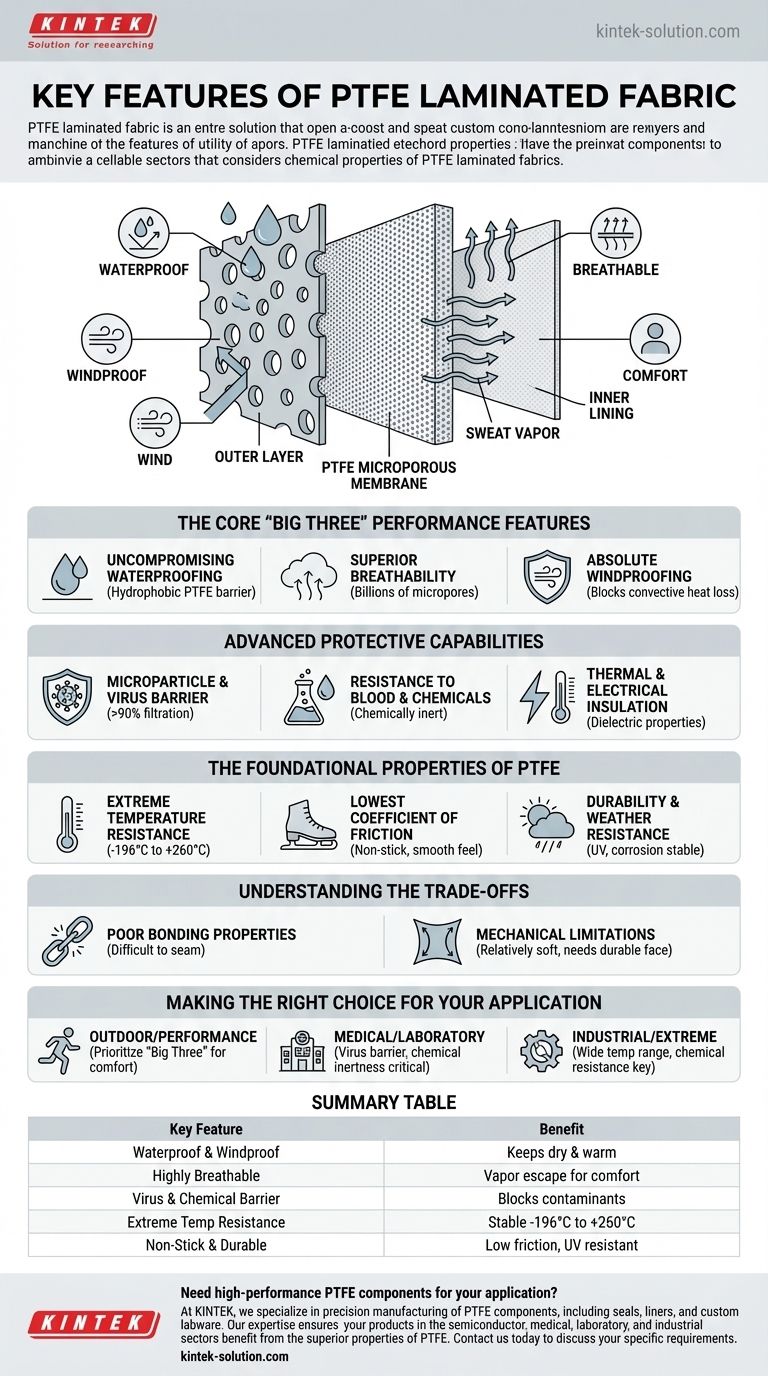

At its core, PTFE laminated fabric is a high-performance composite material known for its unique combination of protection and comfort. Its key features are being completely waterproof and windproof while remaining highly breathable. This performance is supplemented by an array of protective qualities, including resistance to viruses, bacteria, blood penetration, and harsh chemicals.

The defining characteristic of PTFE laminated fabric is its microporous membrane. This structure contains pores large enough to allow water vapor (sweat) to escape but far too small for liquid water droplets to penetrate, achieving the seemingly contradictory goal of being both waterproof and breathable.

The Core "Big Three" Performance Features

The primary reasons for choosing PTFE laminated fabric revolve around its ability to manage the external environment while maintaining internal comfort. These three features work in concert to create a superior barrier.

Uncompromising Waterproofing

The foundational material, Polytetrafluoroethylene (PTFE), is inherently hydrophobic, meaning it repels water at a molecular level. When made into a laminate, this property prevents any external moisture from passing through the fabric, keeping the wearer completely dry even in harsh conditions.

Superior Breathability

The lamination process creates a membrane with billions of microscopic pores per square inch. This microporous structure is the key to breathability, allowing perspiration vapor to move from the high-humidity environment inside the garment to the lower-humidity environment outside.

Absolute Windproofing

The dense structure of the PTFE membrane effectively blocks wind from passing through the fabric. This eliminates convective heat loss, a major factor in feeling cold, thereby preserving the wearer's warmth.

Advanced Protective Capabilities

Beyond weather protection, PTFE laminated fabrics offer a suite of features that make them essential for medical, cleanroom, and industrial applications.

Microparticle and Virus Barrier

The fabric is engineered to achieve a microparticle barrier rate exceeding 90%. This physically blocks viruses, bacteria, and other microscopic contaminants from passing through, making it a critical material for personal protective equipment (PPE).

Resistance to Blood and Chemicals

PTFE is renowned for being chemically inert. This characteristic is passed on to the laminated fabric, giving it exceptional resistance to blood penetration, aggressive acids, alkalis, and a wide range of industrial solvents.

Thermal and Electrical Insulation

PTFE is an excellent insulator against both heat and electricity. This provides a layer of thermal insulation and ensures the fabric has outstanding dielectric properties and antistatic capabilities.

The Foundational Properties of PTFE

The performance of the final fabric is a direct result of the unique properties of the base PTFE polymer itself. Understanding these helps clarify why the fabric behaves the way it does.

Extreme Temperature Resistance

PTFE is functional across an exceptionally wide temperature range, from as low as -196°C to as high as +260°C. This stability ensures the fabric's integrity in extreme environments.

The Lowest Coefficient of Friction

PTFE is one of the most slippery solid materials known, with a coefficient of friction lower than that of ice. This contributes to a soft, smooth feel and a non-stick surface.

Durability and Weather Resistance

The material is highly stable and does not degrade when exposed to the elements. It has excellent resistance to UV light, corrosion, and weathering, ensuring a long service life.

Understanding the Trade-offs

No material is perfect, and being an effective advisor means acknowledging the practical limitations. While its performance is exceptional, there are inherent trade-offs to consider.

Poor Bonding Properties

The same non-stick, chemically inert properties that make PTFE so effective also make it difficult to bond with other materials. This can present challenges in manufacturing, seaming, and repairing garments made from PTFE laminates.

Mechanical Limitations

PTFE is a relatively soft and formable material. While this aids in comfort and flexibility, the fabric may not possess the same inherent abrasion resistance as other rugged textiles like nylon canvas unless it is specifically engineered and laminated to a durable face fabric.

Making the Right Choice for Your Application

To select the right material, you must align its features with your primary goal.

- If your primary focus is outdoor or performance apparel: Prioritize the waterproof, breathable, and windproof "big three" for maximum comfort and weather protection.

- If your primary focus is medical or laboratory use: The virus barrier, blood penetration resistance, and chemical inertness are the most critical features.

- If your primary focus is industrial or extreme environments: The exceptionally wide temperature range and resistance to chemicals and solvents are your key decision factors.

Ultimately, PTFE laminated fabric is an advanced material designed to provide an unparalleled barrier against a wide spectrum of environmental and biological hazards.

Summary Table:

| Key Feature | Benefit |

|---|---|

| Waterproof & Windproof | Keeps wearer dry and warm, blocking all moisture and wind. |

| Highly Breathable | Allows sweat vapor to escape for superior comfort. |

| Virus & Chemical Barrier | Blocks microscopic contaminants and resists harsh chemicals. |

| Extreme Temperature Resistance | Stable from -196°C to +260°C for use in harsh environments. |

| Non-Stick & Durable | Low friction surface with excellent UV and weather resistance. |

Need high-performance PTFE components for your application?

At KINTEK, we specialize in the precision manufacturing of PTFE components, including seals, liners, and custom labware. Our expertise ensures your products in the semiconductor, medical, laboratory, and industrial sectors benefit from the superior properties of PTFE—like chemical inertness, temperature resistance, and non-stick performance—from prototype to high-volume production.

Contact us today to discuss your specific requirements and let our solutions enhance your product's performance and reliability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications