To effectively troubleshoot and maintain systems using PTFE, you must understand its four defining properties: an extremely low coefficient of friction, exceptional chemical inertness, a vast operating temperature range, and excellent electrical insulation. While these characteristics make it incredibly robust, its primary vulnerability lies in its softness and tendency to deform under sustained pressure, a phenomenon known as "creep."

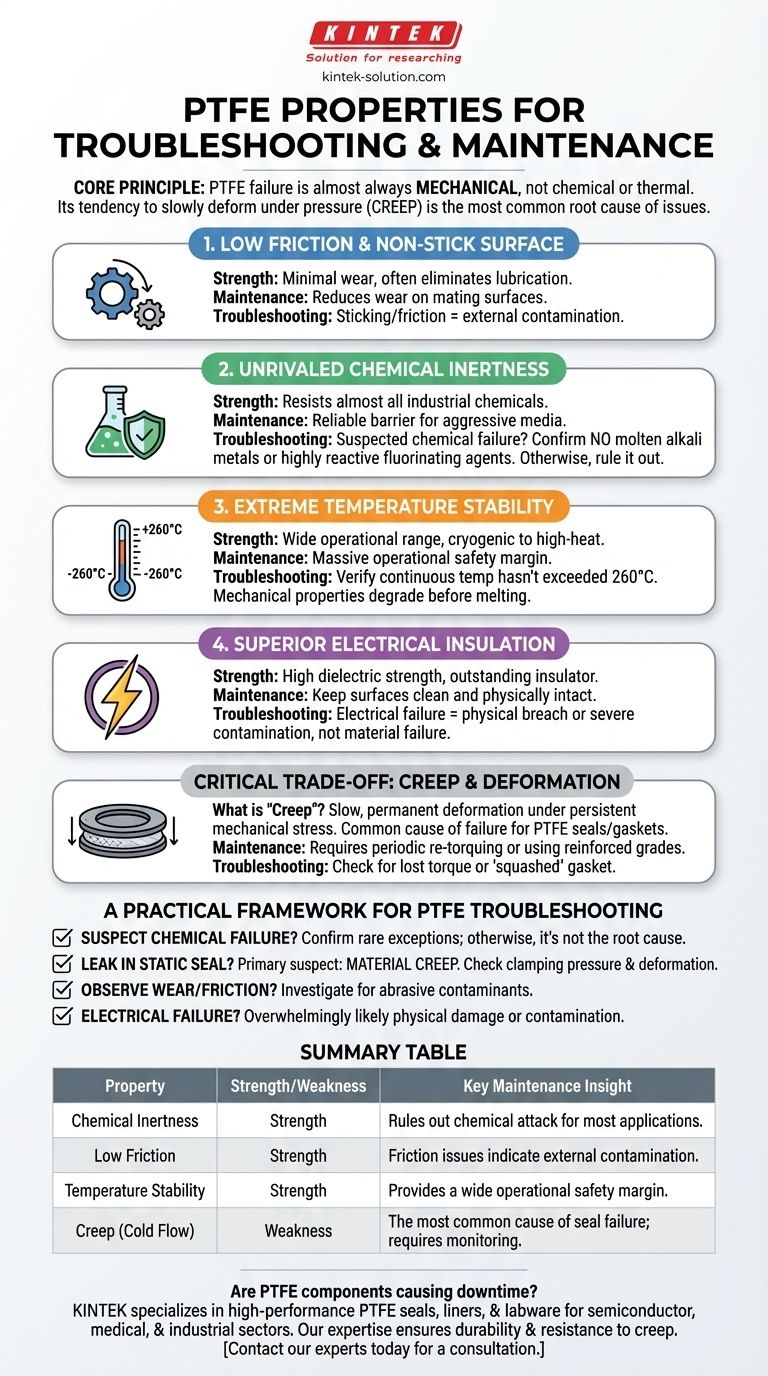

The core principle for troubleshooting Polytetrafluoroethylene (PTFE) is to recognize that its failure is almost always mechanical, not chemical or thermal. Its tendency to slowly deform under pressure is the most common root cause of issues like leaking seals and loosened fittings.

The Core Strengths in an Operational Context

PTFE's reputation is built on its extreme resilience. Understanding the practical application of these strengths helps you quickly rule out potential causes of failure during diagnostics.

Exceptionally Low Friction & Non-Stick Surface

PTFE has one of the lowest coefficients of friction of any known solid. This means parts move against it with minimal resistance.

For maintenance, this property reduces wear on mating surfaces and often eliminates the need for lubrication.

For troubleshooting, if a PTFE-lined component is sticking or showing signs of friction, the cause is almost certainly external contamination, not a failure of the material itself.

Unrivaled Chemical Inertness

PTFE is virtually inert, resisting almost all industrial chemicals, acids, and solvents.

This simplifies maintenance by providing a reliable barrier material for aggressive media.

When troubleshooting a suspected chemical failure, your first step should be to confirm if the system uses one of the very few exceptions: molten alkali metals or highly reactive fluorinating agents like chlorine trifluoride. Outside of these rare cases, chemical degradation can be ruled out.

Extreme Temperature Stability

PTFE maintains its properties across an exceptionally wide temperature range, typically cited as -260°C to +260°C (-436°F to +500°F) for continuous service.

This provides a massive operational safety margin for both cryogenic and high-heat applications.

If you suspect a thermal failure, verify that the component's continuous operating temperature has not exceeded 260°C. While it only melts at around 327°C, its mechanical properties degrade long before that point.

Superior Electrical Insulation

PTFE possesses a high dielectric strength, making it an outstanding electrical insulator, especially at high radio frequencies.

For maintenance, this means ensuring the PTFE surfaces are kept clean and physically intact to maintain their insulating capability.

An electrical failure in a PTFE component is almost never due to the material's inherent properties. The root cause is overwhelmingly likely to be a physical breach, such as a crack, or severe surface contamination creating a conductive path.

Understanding the Critical Trade-off: Creep and Deformation

The most significant challenge when working with PTFE is its softness. This property, which contributes to its excellent sealing ability, is also its primary mechanical weakness.

What is "Creep"?

Creep, or cold flow, is the tendency of a solid material to move slowly or deform permanently under the influence of persistent mechanical stress.

Because PTFE is a relatively soft fluoropolymer, it is prone to creep, especially under compressive loads like those in a gasket or seal.

Why It Matters for Maintenance

Creep is the most common cause of failure for PTFE seals and gaskets. Over time, a bolted flange can lose its clamping pressure not because the bolts have loosened, but because the PTFE gasket has slowly compressed and thinned out.

This requires periodic re-torquing of fasteners in critical applications or using mechanically reinforced (filled) grades of PTFE that are more resistant to creep.

Troubleshooting Signs of Creep

When diagnosing a slow, persistent leak in a static seal, creep should be your primary suspect.

Look for a loss of torque on fasteners, or visually inspect the failed gasket for signs of being "squashed" or extruded from its intended space.

A Practical Framework for PTFE Troubleshooting

Use this checklist to diagnose issues with PTFE components quickly and accurately.

- If you suspect a chemical failure: Confirm if the process involves the rare exceptions like molten alkali metals or specific fluorine compounds. Otherwise, chemical attack is almost never the root cause.

- If you are diagnosing a leak in a static seal: Your primary suspect should be material creep. Check for loss of clamping pressure and signs of physical deformation in the component.

- If you observe surface wear or friction issues: Investigate for abrasive contaminants in the system, as the PTFE itself has an extremely low friction coefficient.

- If you encounter an electrical failure: The root cause is overwhelmingly likely to be physical damage or surface contamination, not an inherent failure of the material's insulating properties.

By understanding that PTFE's primary vulnerability is physical deformation, not chemical or thermal breakdown, you can diagnose and resolve issues with greater speed and accuracy.

Summary Table:

| Property | Strength / Weakness | Key Maintenance Insight |

|---|---|---|

| Chemical Inertness | Strength | Rules out chemical attack for most applications. |

| Low Friction | Strength | Friction issues indicate external contamination. |

| Temperature Stability | Strength | Provides a wide operational safety margin. |

| Creep (Cold Flow) | Weakness | The most common cause of seal failure; requires monitoring. |

Are PTFE components causing downtime in your process? KINTEK specializes in manufacturing high-performance, precision PTFE seals, liners, and labware for the semiconductor, medical, and industrial sectors. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures your components are optimized for durability and resistance to creep. Let's solve your specific challenge. Contact our experts today for a consultation.

Visual Guide

Related Products

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the benefits of using PTFE seals? Unmatched Chemical & Temperature Resistance

- What are the key properties of PTFE that make it suitable for sealing applications? | High-Performance Seals for Extreme Conditions

- What are the five outstanding characteristics of PTFE seals? Engineered for Extreme Performance

- What are the advantages of PTFE-based seals? Unmatched Performance in Extreme Conditions

- What are the primary characteristics of PTFE seals? Unmatched Performance for Extreme Conditions