In industrial manufacturing, Polytetrafluoroethylene (PTFE) is a foundational material used for a vast range of applications due to its unique characteristics. Key uses include creating non-stick and anti-wear coatings for machine parts, manufacturing high-performance seals, gaskets, and valves for chemical processing, and providing superior electrical insulation for wires and cables in demanding sectors like aerospace and semiconductors.

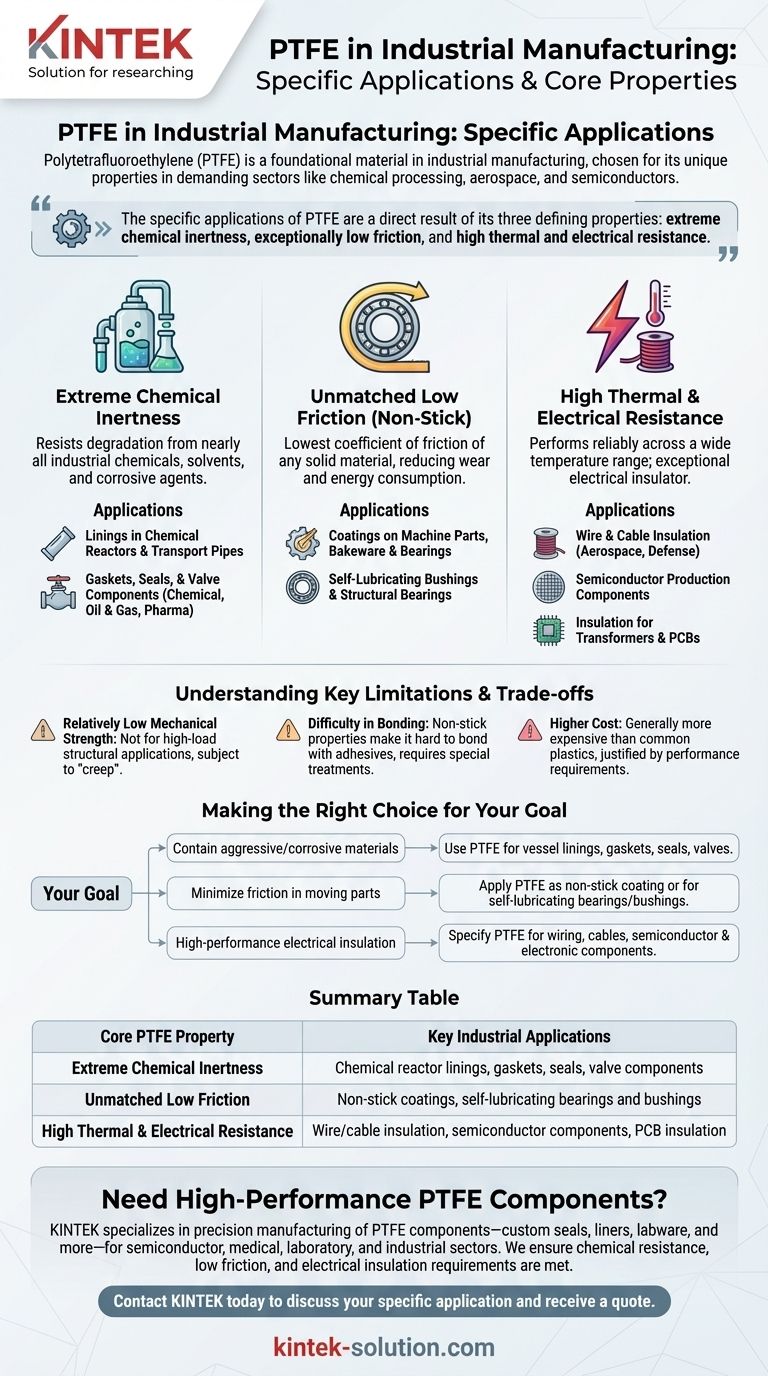

The specific applications of PTFE are not random; they are a direct result of its three defining properties. Understanding that it is chosen for its extreme chemical inertness, exceptionally low friction, and high thermal and electrical resistance is the key to knowing where and why it is used.

The Core Properties Driving PTFE's Versatility

To understand the applications of PTFE, one must first understand its fundamental strengths. Almost every industrial use case can be traced back to one of three core material characteristics.

Extreme Chemical Inertness

PTFE is renowned for being almost completely inert, meaning it resists degradation from nearly all industrial chemicals, solvents, and corrosive agents. This makes it a material of choice for handling aggressive substances.

This property is why PTFE is used extensively for linings in chemical reactors and transport pipes. It is also fabricated into gaskets, seals, and valve components that must maintain integrity while exposed to harsh materials in the chemical, oil & gas, and pharmaceutical industries.

Unmatched Low Friction (Non-Stick)

PTFE has one of the lowest coefficients of friction of any known solid material. This gives it a unique "slipperiness" that is invaluable for reducing wear and energy consumption in mechanical systems.

This low-friction quality is the reason it is used as a coating on industrial bakeware, machine parts, and bearings to prevent sticking and reduce wear. It allows for the creation of self-lubricating bushings and structural bearings that operate smoothly without external lubricants.

High Thermal & Electrical Resistance

PTFE performs reliably across a very wide temperature range and is an exceptional electrical insulator. It does not conduct electricity and can withstand high voltages, making it ideal for electronics and high-performance wiring.

Because of this, it is the standard for wire and cable insulation in critical applications like aerospace and defense. Its stability also makes it essential for manufacturing components used in semiconductor production and for insulating transformers and printed circuit boards.

Understanding Key Limitations and Trade-offs

While incredibly versatile, PTFE is not the solution for every problem. Being an effective advisor means acknowledging where a material falls short.

Relatively Low Mechanical Strength

PTFE is a relatively soft material. It is not suitable for high-load structural applications where rigidity and tensile strength are the primary requirements. It can be subject to "creep," or deformation under sustained pressure.

Difficulty in Bonding

The same non-stick properties that make PTFE so useful also make it very difficult to bond to other materials using conventional adhesives. This often requires special surface treatments like chemical etching to achieve a durable bond.

Higher Cost

As a high-performance polymer, PTFE is generally more expensive than common plastics like polyethylene or polypropylene. Its use is typically justified in applications where its unique properties are a critical performance requirement.

Making the Right Choice for Your Goal

Selecting PTFE is a decision that should be based on a clear operational need. Your specific goal will determine the ideal application.

- If your primary focus is containing aggressive or corrosive materials: Use PTFE for vessel linings, gaskets, seals, and valve components.

- If your primary focus is minimizing friction in moving parts: Apply PTFE as a non-stick coating or use it to manufacture self-lubricating bearings and bushings.

- If your primary focus is high-performance electrical insulation: Specify PTFE for wiring, cables, and critical electronic components, particularly in the aerospace and semiconductor industries.

Ultimately, understanding PTFE's core properties is the key to leveraging its power in any industrial setting.

Summary Table:

| Core PTFE Property | Key Industrial Applications |

|---|---|

| Extreme Chemical Inertness | Chemical reactor linings, gaskets, seals, valve components |

| Unmatched Low Friction | Non-stick coatings, self-lubricating bearings and bushings |

| High Thermal & Electrical Resistance | Wire/cable insulation, semiconductor components, PCB insulation |

Need High-Performance PTFE Components?

KINTEK specializes in the precision manufacturing of PTFE components—including custom seals, liners, labware, and more—for the semiconductor, medical, laboratory, and industrial sectors. Whether you require prototypes or high-volume orders, our expertise ensures your components meet the demanding requirements for chemical resistance, low friction, and electrical insulation.

Contact KINTEK today to discuss your specific application and receive a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Crucibles for Laboratory and Industrial Applications

People Also Ask

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications