To be precise, specialized Teflon™ (PTFE) bearing products are not a single item but a family of materials and forms engineered for specific industrial challenges. The main categories include PTFE bearing strips and tapes for sliding surfaces, metal-backed lined bearings for high loads, solid PTFE bushings and washers for simple movements, and glass-filled PTFE for enhanced strength and wear resistance.

The critical insight is that the term "Teflon bearing" refers less to a specific part and more to a material system. The specialization comes from combining PTFE's low friction with specific physical forms and filler materials to overcome the softness of pure PTFE.

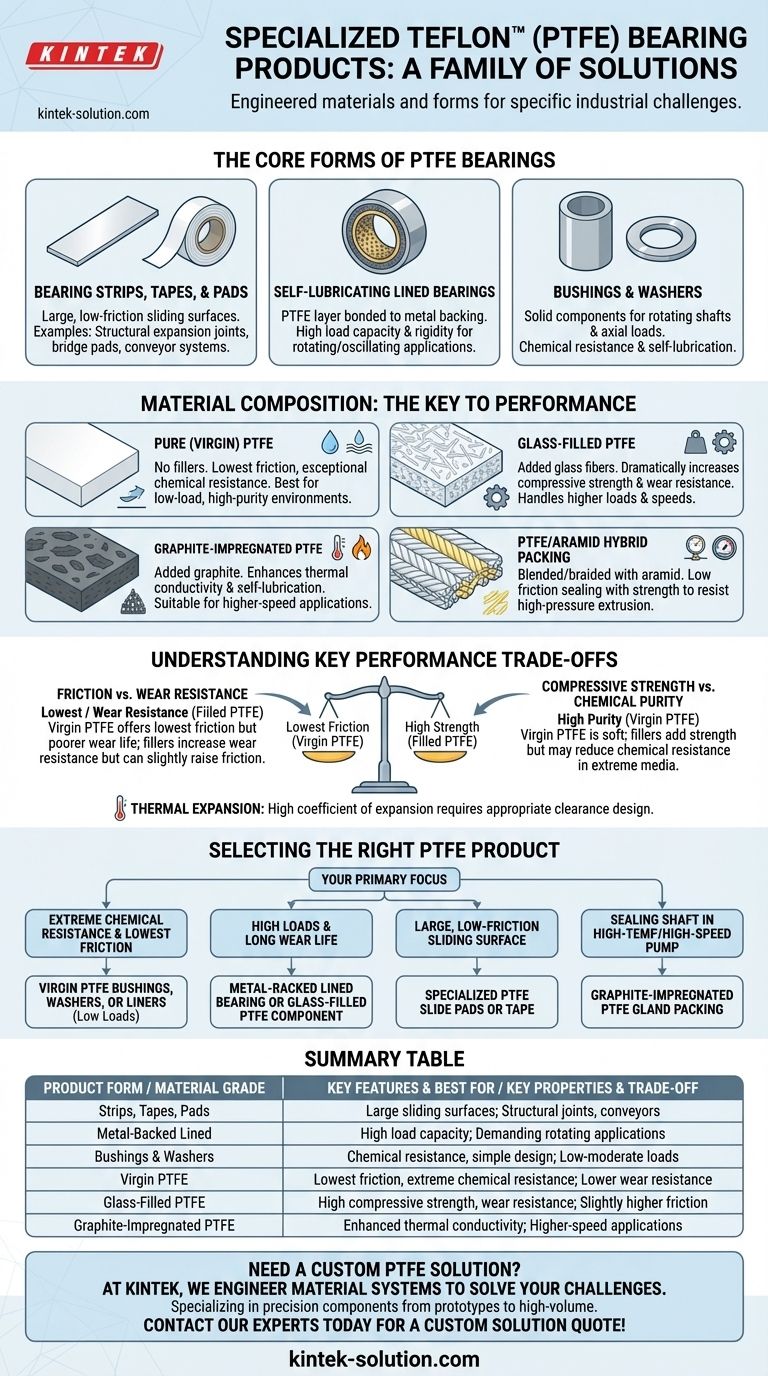

The Core Forms of PTFE Bearings

The physical shape and construction of a PTFE bearing are the first level of specialization, dictating how it is integrated into an assembly.

Bearing Strips, Tapes, and Pads

These products provide a simple way to create a large, low-friction sliding surface. They are essentially sheets or strips of PTFE material.

They are commonly used in applications like structural expansion joints, bridge bearing pads, and conveyor systems where smooth, stick-slip-free movement is required.

Self-Lubricating Lined Bearings

This is a highly common and effective composite design. A thin layer of PTFE, often woven with other fibers, is bonded to a rigid metal backing (like steel or bronze).

This construction combines the low-friction surface of PTFE with the high load-bearing capacity and rigidity of the metal shell, making it ideal for demanding rotating or oscillating applications.

Bushings and Washers

These are the simplest forms, consisting of solid components machined from a specific grade of PTFE material.

Bushings (or sleeve bearings) are used for rotating shafts, while thrust washers handle axial loads. They are excellent for applications with low to moderate loads where chemical resistance and self-lubrication are paramount.

Material Composition: The Key to Performance

The true specialization of a PTFE bearing lies in its material composition. Pure PTFE is soft and can deform under load, so fillers are added to enhance specific mechanical properties.

Pure (Virgin) PTFE

This formulation contains no fillers. Its primary advantages are the lowest coefficient of friction of any solid and exceptional chemical resistance.

It is best suited for low-load applications, laboratory equipment, or environments with highly corrosive chemicals where material purity is essential.

Glass-Filled PTFE

Adding microscopic glass fibers is one of the most common ways to improve PTFE. This filler dramatically increases compressive strength and wear resistance.

Glass-filled PTFE is a go-to choice for bearings and seals that must handle higher loads and speeds than virgin PTFE can withstand.

Graphite-Impregnated PTFE

Graphite is another common filler, often combined with others like carbon. It enhances thermal conductivity, helping to dissipate heat from the bearing surface.

This grade also improves self-lubrication, making it suitable for higher-speed applications or as a material for gland packing in pumps and valves.

PTFE/Aramid Hybrid Packing

In high-pressure sealing applications, PTFE is often blended or braided with aramid fibers (like Kevlar®).

The PTFE provides the low-friction, chemically inert sealing surface, while the tough aramid fibers provide the strength to resist extrusion under high pressure.

Understanding Key Performance Trade-offs

Selecting the right PTFE product requires balancing its inherent advantages against its limitations. No single formulation is perfect for every scenario.

Friction vs. Wear Resistance

There is a direct trade-off here. Virgin PTFE offers the absolute lowest friction but has relatively poor wear life under load.

Adding fillers like glass or bronze significantly increases wear resistance and load capacity but can slightly increase the coefficient of friction.

Compressive Strength vs. Chemical Purity

Pure PTFE is relatively soft and susceptible to "creep," or slow deformation under a constant load.

Fillers are the solution for increasing strength, but they can reduce the material's overall chemical resistance in certain aggressive media. For the most extreme chemical environments, virgin PTFE remains the superior choice.

Thermal Expansion

A critical design consideration for all PTFE grades is their high coefficient of thermal expansion. The material expands and contracts more than metals with temperature changes.

Engineers must account for this by designing in appropriate clearance to prevent the bearing from seizing or failing when operating temperatures fluctuate.

Selecting the Right PTFE Product for Your Application

Your choice should be driven entirely by the primary demands of your specific engineering problem.

- If your primary focus is extreme chemical resistance and the lowest possible friction: Virgin PTFE bushings, washers, or liners are the correct choice, provided loads are low.

- If your primary focus is supporting high loads and ensuring long wear life: A metal-backed, PTFE-lined bearing or a component made from glass-filled PTFE is the superior solution.

- If your primary focus is creating a large, low-friction sliding surface: Use specialized PTFE slide bearing pads or adhesive-backed PTFE tape.

- If your primary focus is sealing a shaft in a high-temperature or high-speed pump: Select a graphite-impregnated PTFE gland packing to manage heat and maintain lubrication.

Understanding these material and form-factor variations allows you to leverage PTFE not as a single product, but as a versatile problem-solving platform.

Summary Table:

| Product Form | Key Features | Best For |

|---|---|---|

| Strips, Tapes, Pads | Large, low-friction sliding surfaces | Structural joints, bridge bearings, conveyors |

| Metal-Backed Lined Bearings | High load capacity, self-lubricating | Demanding rotating/oscillating applications |

| Bushings & Washers | Chemical resistance, simple design | Low-moderate load rotating shafts, axial loads |

| Material Grade | Key Properties | Performance Trade-off |

| Virgin PTFE | Lowest friction, extreme chemical resistance | Lower wear resistance, prone to creep |

| Glass-Filled PTFE | High compressive strength, wear resistance | Slightly higher friction than virgin PTFE |

| Graphite-Impregnated PTFE | Enhanced thermal conductivity, self-lubrication | Ideal for higher-speed applications |

Need a Custom PTFE Solution for Your Precision Application?

At KINTEK, we don't just supply PTFE components—we engineer material systems to solve your specific challenges. Whether you're in the semiconductor, medical, laboratory, or industrial sector, our expertise in custom fabrication ensures you get the right combination of PTFE form and filler material for optimal performance.

We specialize in manufacturing precision PTFE components like seals, liners, and labware, offering everything from prototypes to high-volume orders. Let us help you balance friction, wear resistance, and chemical purity for your unique requirements.

Contact our experts today to discuss your project and receive a custom solution quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications