Beyond its famous non-stick pans, Teflon's industrial applications are vast and critical, primarily revolving around its use as a high-performance coating for industrial equipment, a superior insulator for electrical components, and an essential sealing material for high-pressure and chemically aggressive systems. Its utility stems from a unique combination of properties, including extreme chemical inertness, high heat resistance, and one of the lowest coefficients of friction of any solid material.

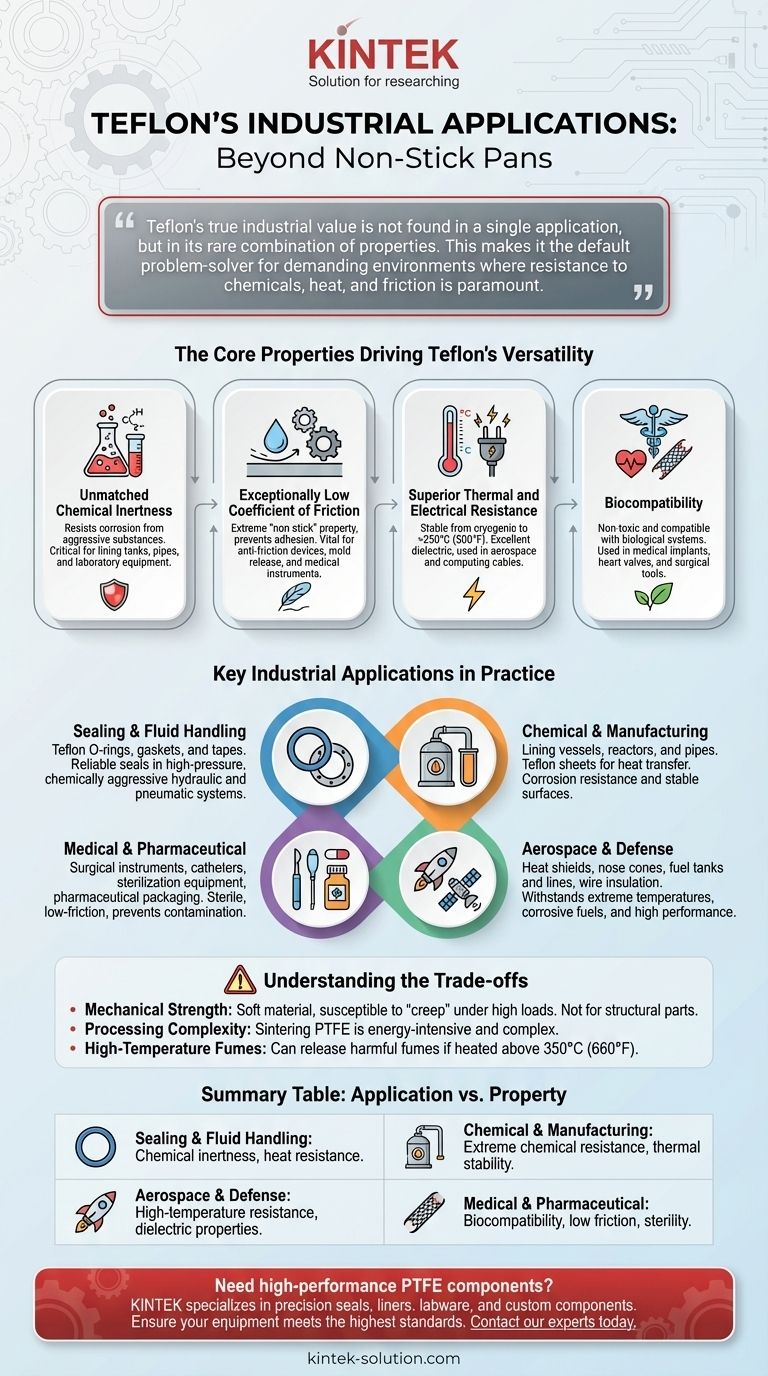

Teflon's true industrial value is not found in a single application, but in its rare combination of properties. This makes it the default problem-solver for demanding environments where resistance to chemicals, heat, and friction is paramount.

The Core Properties Driving Teflon's Versatility

Teflon is not a single material but a brand name for a family of fluoropolymers, most famously Polytetrafluoroethylene (PTFE). Its widespread adoption is a direct result of its fundamental material characteristics.

Unmatched Chemical Inertness

Teflon is exceptionally non-reactive and resists corrosion from the vast majority of industrial chemicals. This makes it an indispensable material for handling and storing aggressive substances.

This property is critical for lining chemical tanks, pipes, and laboratory equipment, ensuring both the integrity of the equipment and the purity of the material being handled.

Exceptionally Low Coefficient of Friction

Known as the "non-stick" property, Teflon’s extremely low friction surface prevents other materials from adhering to it.

While famous in cookware, this is vital for industrial anti-friction devices, coatings on molds to allow easy release of parts, and low-friction surfaces on medical instruments to minimize tissue damage.

Superior Thermal and Electrical Resistance

Teflon maintains its stability across a wide range of temperatures, from cryogenic lows to highs of over 250°C (500°F).

It is also an excellent electrical insulator, or dielectric. This makes it the material of choice for insulating high-frequency, high-performance wiring and cables in aerospace and computing.

Biocompatibility

Teflon is non-toxic and compatible with biological systems, meaning it can be used inside the human body without causing an adverse reaction.

This has led to its use in medical applications such as artificial heart valves, dentures, and coatings for surgical appliances.

Key Industrial Applications in Practice

These core properties translate directly into solutions for some of industry's toughest challenges.

Sealing and Fluid Handling

Teflon O-rings, gaskets, and tapes are crucial for creating reliable seals in demanding environments.

They are used in high-pressure hydraulic and pneumatic systems where they prevent leaks of aggressive fluids or gases, ensuring equipment stability and safety.

Chemical and Manufacturing

Due to its corrosion resistance, Teflon is used to line vessels, reactors, and pipes in the chemical processing industry.

Teflon sheets are also used in heat transfer processes where a clean, non-reactive, and stable surface is required to ensure precise results.

Aerospace and Defense

The aerospace industry relies on Teflon for its ability to withstand extreme conditions.

It is used in heat shields and nose cones for thermal protection and in fuel tanks and lines due to its resistance to corrosive fuels and wide temperature tolerance.

Medical and Pharmaceutical

Teflon provides a sterile, low-friction coating for surgical instruments, catheters, and sterilization equipment.

Its inertness also makes it ideal for pharmaceutical packaging and other applications where preventing contamination is critical.

Understanding the Trade-offs

While incredibly versatile, Teflon is not a universal solution. Understanding its limitations is key to its proper application.

Mechanical Strength

Standard PTFE is a relatively soft material. Under high mechanical loads, it can be susceptible to "creep" or cold flow, meaning it can deform over time. It is not typically used for structural components.

Processing Complexity

Unlike many common plastics that can be easily melt-processed and molded, sintering PTFE is a more complex and energy-intensive process.

High-Temperature Fumes

While highly heat-resistant, if heated beyond its decomposition temperature (around 350°C or 660°F), Teflon can release potentially harmful fumes. This is primarily a concern in applications with uncontrolled or extreme heat exposure.

Making the Right Choice for Your Application

Selecting Teflon depends entirely on the problem you need to solve. Its unique properties make it the ideal choice for specific, high-stakes challenges.

- If your primary focus is preventing contamination and corrosion: Teflon's chemical inertness makes it the standard for lining pipes, tanks, and laboratory equipment.

- If your primary focus is reducing friction and wear: Its "non-stick" surface is essential for high-performance bearings, anti-friction devices, and coatings on molds.

- If your primary focus is reliable sealing in extreme environments: Teflon O-rings and gaskets provide unmatched performance against high temperatures and aggressive chemicals.

- If your primary focus is electrical performance and safety: Its dielectric properties are critical for insulating high-frequency wires and sensitive electronic components.

Ultimately, understanding Teflon's core properties is the key to leveraging its power in solving critical industrial challenges.

Summary Table:

| Application Area | Key Teflon Uses | Key Properties Utilized |

|---|---|---|

| Sealing & Fluid Handling | O-rings, gaskets, tapes | Chemical inertness, heat resistance |

| Chemical & Manufacturing | Tank linings, reactor liners, heat transfer sheets | Extreme chemical resistance, thermal stability |

| Aerospace & Defense | Heat shields, fuel lines, wire insulation | High-temperature resistance, excellent dielectric properties |

| Medical & Pharmaceutical | Surgical instruments, catheters, packaging | Biocompatibility, low friction, sterility |

Need high-performance PTFE components for your industrial application? KINTEK specializes in manufacturing precision PTFE seals, liners, labware, and custom components for the semiconductor, medical, laboratory, and industrial sectors. From prototypes to high-volume orders, we ensure your equipment meets the highest standards for chemical resistance, thermal stability, and reliability. Contact our experts today to discuss your custom fabrication needs!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers