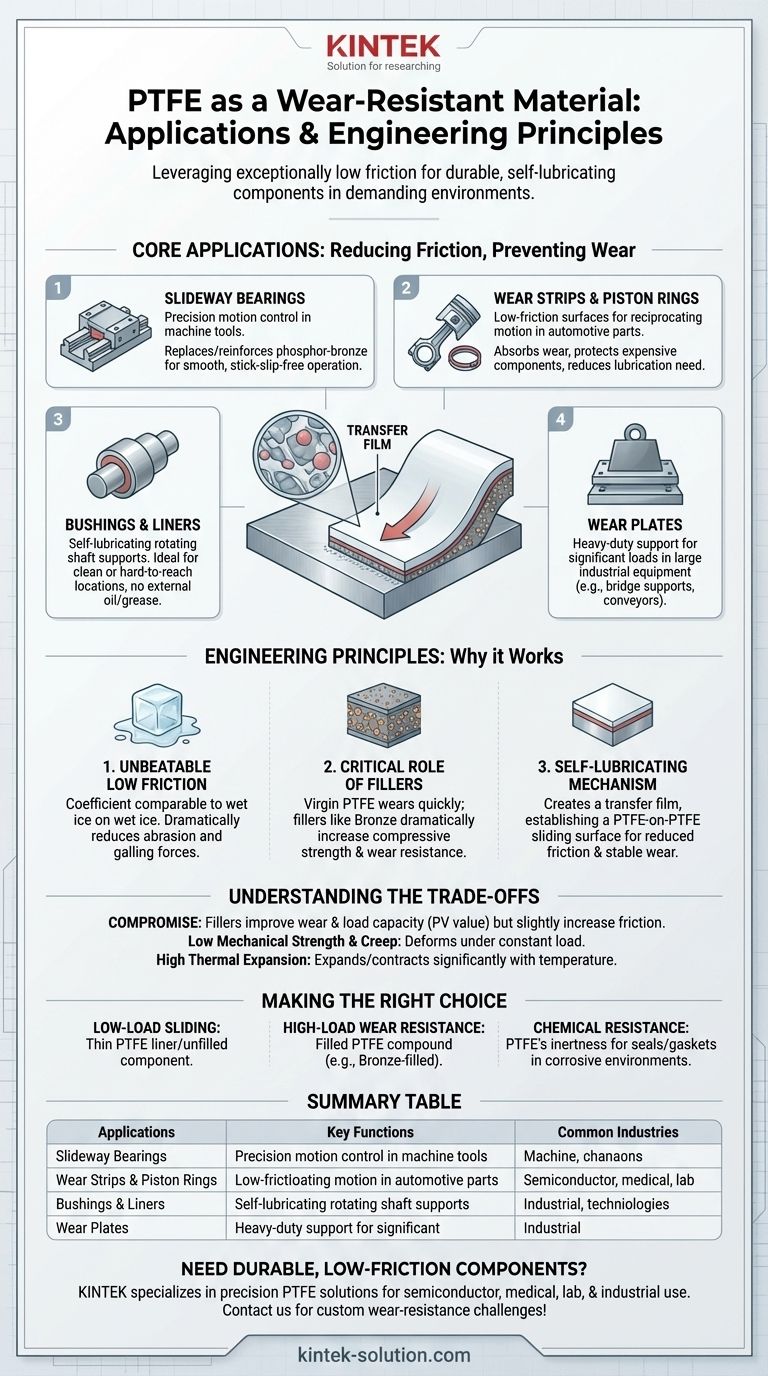

The primary applications of Polytetrafluoroethylene (PTFE) as a wear-resistant material include slideway bearings, wear strips, piston rings, bushings, and wear plates. These components are critical in machinery where reducing friction and preventing wear on metal parts is essential. They leverage PTFE's unique properties to create self-lubricating, durable surfaces in demanding industrial environments.

While famous as a non-stick coating, PTFE’s role as a wear-resistant material is not due to hardness, but to its exceptionally low friction. When reinforced with fillers, it creates high-performance, self-lubricating components that protect and extend the life of critical machinery.

Core Applications in Detail

The versatility of PTFE allows it to be shaped into various components that serve as sacrificial, low-friction interfaces between moving metal parts.

Slideway Bearings

In the machine tool industry, filled PTFE slideway bearings are used to replace or reinforce traditional phosphor-bronze guideways.

They provide a smooth, stick-slip-free motion, which is critical for precision machining operations.

Wear Strips & Piston Rings

Wear strips are commonly found in sub-assemblies like shock absorber struts and automotive pistons, providing a low-friction surface for reciprocating motion.

Similarly, PTFE piston rings are fitted onto piston shafts. They absorb wear and prevent damage to the more expensive piston and cylinder components, all while reducing the need for lubrication.

Bushings & Liners

PTFE can be machined into solid bushings for rotating shafts or applied as a thin layer onto metallic bushings.

This creates a self-lubricating bearing that requires no external oil or grease, making it ideal for clean environments or hard-to-reach locations.

Wear Plates

For heavy-duty applications, thick wear plates (often over 10mm) are used in large industrial equipment.

These plates support significant loads while allowing for slow, controlled movement, such as in bridge supports or heavy-duty conveyor systems.

The Engineering Principles Behind PTFE's Effectiveness

Understanding why PTFE is chosen for these applications is key to using it correctly. Its effectiveness stems from a unique combination of properties, especially when it is modified into a composite material.

Unbeatable Low Coefficient of Friction

PTFE has one of the lowest coefficients of friction of any solid material, comparable to wet ice on wet ice. This inherent "slipperiness" is the primary reason it prevents wear—it dramatically reduces the forces that cause abrasion and galling between surfaces.

The Critical Role of Fillers

Pure, or "virgin," PTFE is relatively soft and can wear quickly under high loads. Its performance as a wear material is transformed by adding fillers.

The most common composition for wear resistance is bronze-filled PTFE. Bronze dramatically increases compressive strength and wear resistance. Other fillers like carbon, graphite, and glass fibers are also used to enhance specific properties.

The Self-Lubricating Mechanism

Filled PTFE components create a self-lubricating system through a process called transfer film.

As the component begins to wear, it deposits a microscopic layer of PTFE onto the mating metal surface. Once this film is established, the moving part is sliding on a PTFE-on-PTFE surface, which further reduces friction and stabilizes the wear rate.

Understanding the Trade-offs

No material is perfect. Acknowledging PTFE's limitations is crucial for successful engineering design.

Compromise Between Friction and Wear

Adding fillers like bronze to PTFE significantly improves its wear rate and load-bearing capacity (its PV value).

However, this comes at the cost of a slightly higher coefficient of friction compared to pure PTFE. The trade-off is almost always worthwhile, as the increase in durability far outweighs the minor increase in friction.

Low Mechanical Strength and Creep

Even when filled, PTFE is not as strong as metal. It is susceptible to "creep," which is the tendency to slowly deform over time when under a constant load. This must be accounted for in the design of components, especially in high-pressure applications.

High Thermal Expansion

PTFE expands and contracts with temperature changes more than most metals. Engineers must design components with appropriate clearances to ensure parts do not bind or become loose as operating temperatures fluctuate.

Making the Right Choice for Your Application

Selecting the correct form of PTFE is directly tied to the specific demands of your project.

- If your primary focus is low-friction sliding in a low-load system: A thin PTFE liner or an unfilled component may be sufficient to create a self-lubricating surface.

- If your primary focus is high-load wear resistance in machinery: A filled PTFE compound, such as bronze-filled PTFE, is the definitive choice for its superior strength and durability.

- If your primary focus is chemical resistance in a moving part: PTFE's exceptional chemical inertness makes it ideal for seals, bearings, and gaskets operating in corrosive environments.

Ultimately, selecting the right PTFE formulation transforms a friction and wear problem into a durable, self-lubricating solution.

Summary Table:

| Application | Key Function | Common Industries |

|---|---|---|

| Slideway Bearings | Precision motion control | Machine Tool, Automation |

| Wear Strips & Piston Rings | Reciprocating motion surfaces | Automotive, Aerospace |

| Bushings & Liners | Self-lubricating rotating shafts | Medical, Laboratory |

| Wear Plates | Heavy-load sliding surfaces | Industrial, Construction |

Need durable, low-friction components for your machinery? KINTEK specializes in precision PTFE components (seals, liners, labware, and custom fabrications) for semiconductor, medical, laboratory, and industrial applications. We help you reduce maintenance costs and extend equipment lifespan through custom solutions from prototypes to high-volume orders. Contact our experts today to discuss your specific wear-resistance challenges!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments