At its core, Polytetrafluoroethylene (PTFE) is a high-performance fluoropolymer defined by a unique combination of extreme chemical inertness, an exceptionally low coefficient of friction, and stability across a vast temperature range. These characteristics stem from the incredibly strong bonds between its carbon and fluorine atoms, making it one of the most versatile problem-solving materials in modern engineering.

The defining characteristic of PTFE is not a single property, but its rare ability to combine near-total chemical immunity, world-class non-stick performance, and excellent thermal stability. This makes it the material of choice for applications where other polymers would quickly fail.

The Foundation: Unmatched Chemical Inertness

The primary reason for PTFE's remarkable stability is its molecular structure. This foundational inertness is the source of many of its other valuable properties.

The Power of the Carbon-Fluorine Bond

The bond between carbon and fluorine atoms is one of the strongest in organic chemistry. PTFE is essentially a long chain of carbon atoms completely shielded by a sheath of fluorine atoms, leaving no chemically vulnerable points for other substances to attack.

Extreme Chemical and Corrosion Resistance

As a result of its strong bonds, PTFE is resistant to virtually all chemicals, solvents, and corrosive agents. This makes it an ideal material for seals, gaskets, and linings in aggressive chemical processing environments.

Biocompatibility and Food Safety

PTFE is non-toxic, inert, and does not support biological growth. This biocompatibility has led to its widespread use in medical devices and its approval by the FDA for food contact applications.

Unrivaled Surface Performance

PTFE is perhaps most famous for its surface properties, which are a direct result of its low surface energy.

The Lowest Friction Coefficient

PTFE possesses one of the lowest coefficients of friction of any known solid material. This allows it to function as a self-lubricating surface, making it indispensable for high-performance, non-stick coatings and low-friction bearings.

Non-Stick and Hydrophobic

Its low surface energy means that very few materials will permanently adhere to it. This "non-stick" quality, combined with its resistance to water (hydrophobicity) and low moisture absorption, is critical for cookware, coatings, and moisture-resistant seals.

Resilience Across Extreme Temperatures

Few materials can match PTFE's ability to perform reliably across such an extreme spectrum of temperatures.

Exceptionally Wide Operating Range

PTFE maintains its properties over a vast temperature window, operating effectively from cryogenic conditions at -200°C (-328°F) up to a continuous service temperature of +260°C (500°F).

High Thermal Stability

It has a very high melting point of approximately 327°C (621°F) and does not degrade significantly at temperatures below this. This thermal stability allows it to be used in high-temperature electrical and mechanical applications.

Superior Electrical Insulation

PTFE's chemical structure also makes it an outstanding electrical insulator, particularly for high-frequency signals.

High Dielectric Strength

It has a very high resistance to the flow of electricity, making it an excellent material for insulating wires and cables.

Low Dielectric Constant

PTFE's low dielectric constant means it absorbs very little electromagnetic energy. This makes it the preferred insulator for high-frequency applications like coaxial cables and printed circuit boards used in RF and microwave systems.

Understanding the Trade-offs

While its properties are exceptional, PTFE is not the solution for every problem. Understanding its limitations is critical for proper material selection.

Low Mechanical Strength

Compared to other engineering plastics, PTFE is relatively soft and has poor tensile strength. It is susceptible to "creep," or deformation over time when subjected to a constant load.

Manufacturing Challenges

PTFE's high viscosity when molten prevents it from being processed by conventional methods like injection molding or extrusion. It typically requires specialized compression molding and sintering processes.

Abrasion Resistance

While it has a low-friction surface, PTFE itself is not exceptionally hard. In high-abrasion applications, it can wear relatively quickly unless it is combined with fillers like glass, carbon, or graphite to improve durability.

Making the Right Choice for Your Goal

Selecting PTFE is about matching its unique strengths to a specific engineering challenge.

- If your primary focus is extreme chemical resistance: PTFE is the definitive choice for seals, linings, and components exposed to aggressive acids, bases, and solvents.

- If your primary focus is low friction and non-stick surfaces: PTFE is the industry standard for coatings on cookware, self-lubricating bearings, and surfaces requiring easy release.

- If your primary focus is high-frequency electrical performance: PTFE's low dielectric constant makes it the superior material for insulating critical RF and microwave cables and components.

- If your primary focus is performance across a wide temperature range: PTFE provides reliable mechanical and chemical properties from cryogenic lows to high-heat industrial applications.

Ultimately, PTFE should be viewed as a specialized material designed to succeed where conventional polymers fail due to chemical attack, extreme temperatures, or the need for an ultra-low-friction surface.

Summary Table:

| Key Property | Description | Key Benefit |

|---|---|---|

| Chemical Inertness | Resistant to virtually all chemicals and solvents. | Ideal for seals and linings in aggressive environments. |

| Low Coefficient of Friction | One of the lowest of any known solid material. | Excellent for non-stick coatings and self-lubricating parts. |

| Wide Temperature Range | Stable from -200°C to +260°C. | Reliable performance in extreme cryogenic and high-heat conditions. |

| Superior Electrical Insulation | High dielectric strength and low dielectric constant. | Preferred for high-frequency cables and critical components. |

Leverage the unique properties of PTFE for your most demanding applications.

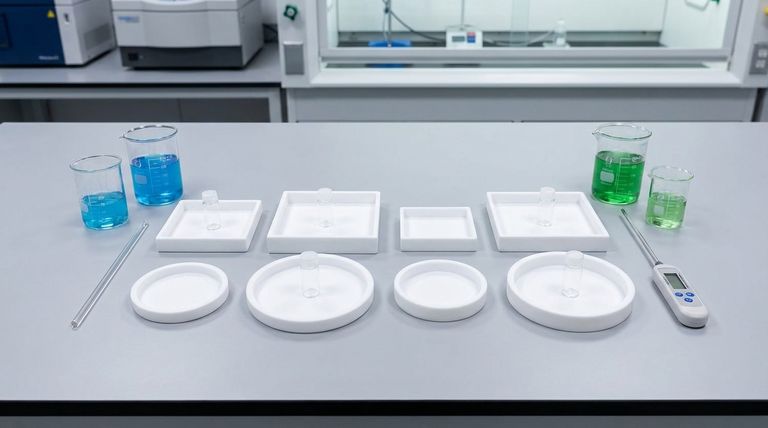

KINTEK specializes in the precision manufacturing of high-performance PTFE components—including custom seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you need a prototype or a high-volume production run, our expertise ensures your components meet the highest standards for chemical resistance, thermal stability, and low friction.

Ready to solve your toughest engineering challenges? Contact KINTEB today to discuss your custom PTFE fabrication needs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications