The most innovative applications of CNC machined PTFE are found where high precision is required to leverage the material's unique properties, such as in custom medical implants, high-frequency electronic insulators, and critical seals for aerospace fuel systems. These are not off-the-shelf parts; they are custom-engineered components designed to solve extreme environmental or performance challenges that other materials cannot.

The core insight is that innovation with PTFE doesn't come from the material alone, but from the combination of its extreme properties—like chemical inertness and near-zero friction—with the precision and geometric freedom of CNC machining. This pairing allows for the creation of bespoke components that enable breakthroughs in demanding fields.

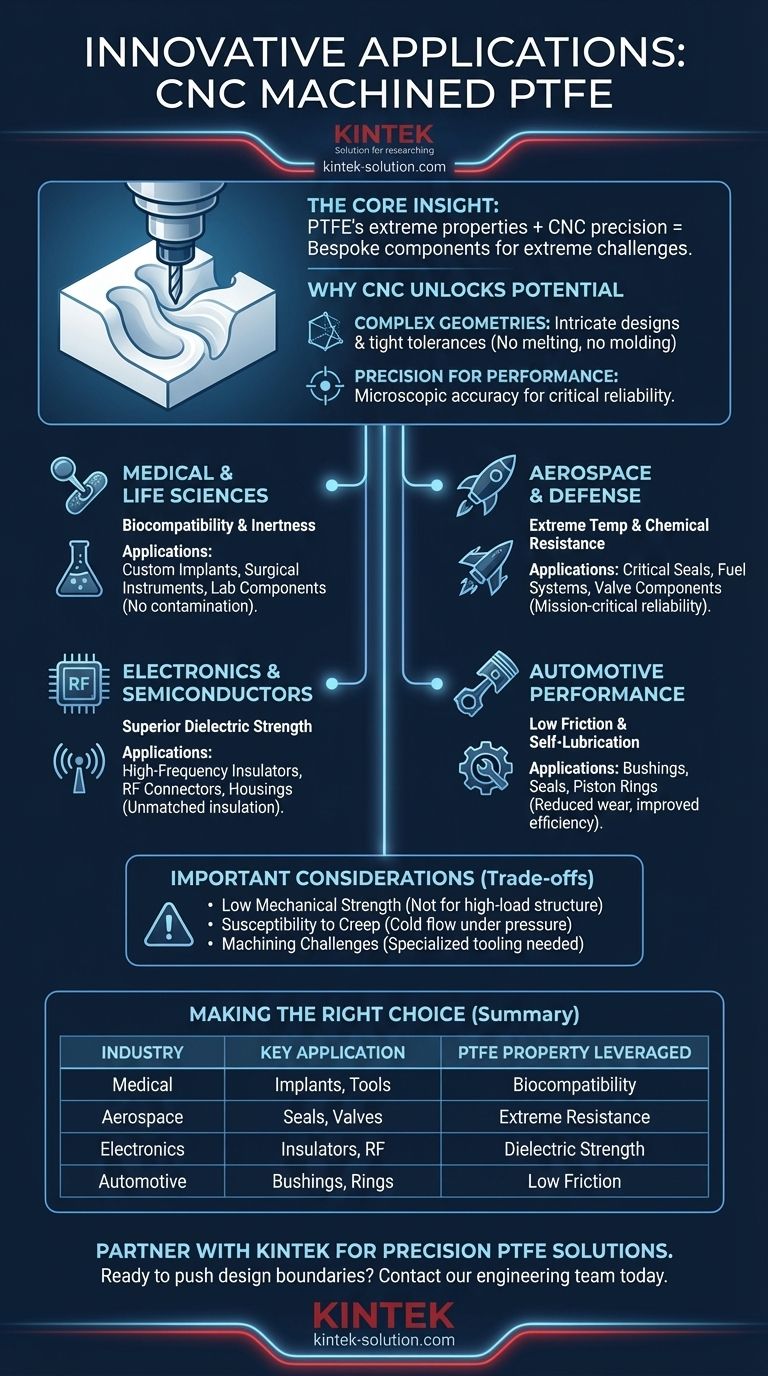

Why CNC Machining Unlocks PTFE's Potential

Polytetrafluoroethylene (PTFE), often known by the brand name Teflon, has a unique molecular structure that gives it remarkable properties. However, this same structure makes it difficult to process using common methods like injection molding. CNC machining becomes the essential manufacturing process to harness its full potential.

Achieving Complex Geometries

PTFE does not melt and flow like other thermoplastics, which severely limits molding. CNC machining is therefore the primary method for creating parts with intricate designs, tight tolerances, and complex features.

Precision for Critical Performance

Applications in aerospace, medical, and semiconductor industries demand microscopic precision. CNC machining delivers the required tolerances for components like custom seals, insulators, and fluidic manifolds, ensuring reliability and performance.

Innovative Applications by Industry

The true innovation is seen in how designers apply PTFE's properties to solve specific, high-stakes problems in various sectors.

Medical & Life Sciences: Biocompatibility

PTFE is almost completely inert and highly biocompatible, meaning it does not react with bodily tissues or fluids.

When machined, it can be crafted into custom surgical instruments, implantable devices like vascular grafts, and high-purity components for lab instrumentation and diagnostic equipment that require no contamination.

Aerospace & Defense: Extreme Reliability

Aerospace systems operate in extreme conditions, from cryogenic temperatures to contact with corrosive fuels.

CNC machined PTFE is used for custom seals, gaskets, and valve components in fuel and hydraulic systems. Its chemical resistance and wide operational temperature range prevent material degradation and ensure mission-critical reliability.

Electronics & Semiconductors: Unmatched Insulation

PTFE has one of the best dielectric strengths of any solid material, making it an exceptional electrical insulator, especially for high-frequency signals.

It is machined into high-performance insulators for RF connectors, housings for sensitive electronics, and components used in semiconductor fabrication, where both electrical performance and chemical purity are essential.

Automotive Performance: Reducing Friction

The extremely low coefficient of friction of PTFE makes it a "self-lubricating" material, ideal for parts that move against each other.

In performance engineering, it is machined into custom bushings, seals, and piston rings that reduce wear and improve efficiency and durability without the need for external lubricants.

Understanding the Trade-offs

While its properties are exceptional, PTFE is not a universal solution. An objective understanding of its limitations is critical for successful product design.

Low Mechanical Strength

PTFE is a relatively soft material with low tensile strength compared to other engineering plastics like PEEK. It is not suitable for high-load structural components.

Susceptibility to Creep

Under sustained pressure, PTFE can deform over time in a process known as creep or "cold flow." This must be accounted for in designs, especially for seals and gaskets under constant compression.

Machining Challenges

The softness that makes PTFE self-lubricating can also make it challenging to machine to extremely tight tolerances. Specialized tooling and expertise are required to prevent deformation and achieve a clean finish.

Making the Right Choice for Your Design

Choosing PTFE is a strategic decision based on solving a specific design challenge that leverages its unique strengths.

- If your primary focus is biocompatibility and chemical inertness: PTFE is an ideal choice for medical, pharmaceutical, or laboratory components that cannot tolerate any material reaction or contamination.

- If your primary focus is electrical insulation at high frequencies: PTFE is one of the best materials available for insulators in radio frequency, microwave, and high-speed digital applications.

- If your primary focus is the lowest possible friction: Use PTFE for custom bearings, slide plates, or seals where self-lubrication is critical for performance and longevity.

- If your primary focus is high mechanical strength or rigidity: You should evaluate harder engineering plastics or metals, as PTFE will likely deform under significant structural load.

By understanding both its unique strengths and its inherent limitations, you can leverage CNC machined PTFE to solve design challenges that other materials simply cannot address.

Summary Table:

| Industry | Key Application | PTFE Property Leveraged |

|---|---|---|

| Medical & Life Sciences | Custom surgical instruments, implants, lab components | Biocompatibility, Chemical Inertness |

| Aerospace & Defense | Critical seals, gaskets, valve components | Extreme temperature resistance, Chemical resistance |

| Electronics & Semiconductors | High-frequency insulators, RF connectors | Superior dielectric strength |

| Automotive Performance | Self-lubricating bushings, seals, piston rings | Extremely low coefficient of friction |

Ready to push the boundaries of your product design with precision CNC machined PTFE components?

At KINTEK, we specialize in manufacturing high-performance PTFE seals, liners, labware, and custom components for the most demanding applications in the semiconductor, medical, laboratory, and industrial sectors. Our expertise in precision production and custom fabrication—from prototypes to high-volume orders—ensures your design leverages the full potential of PTFE's unique properties.

Contact our engineering team today to discuss your specific requirements and get a quote for your project.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications