While widely known for non-stick pans and industrial seals, Polytetrafluoroethylene (PTFE) is experiencing a resurgence in advanced sectors. Its unique combination of properties is now being leveraged to solve complex engineering challenges in aerospace, the medical field, and renewable energy systems.

The core reason for PTFE's emerging applications isn't a change in the material itself, but a growing demand in high-tech industries for its extreme performance characteristics—namely, its chemical inertness, biocompatibility, and thermal stability.

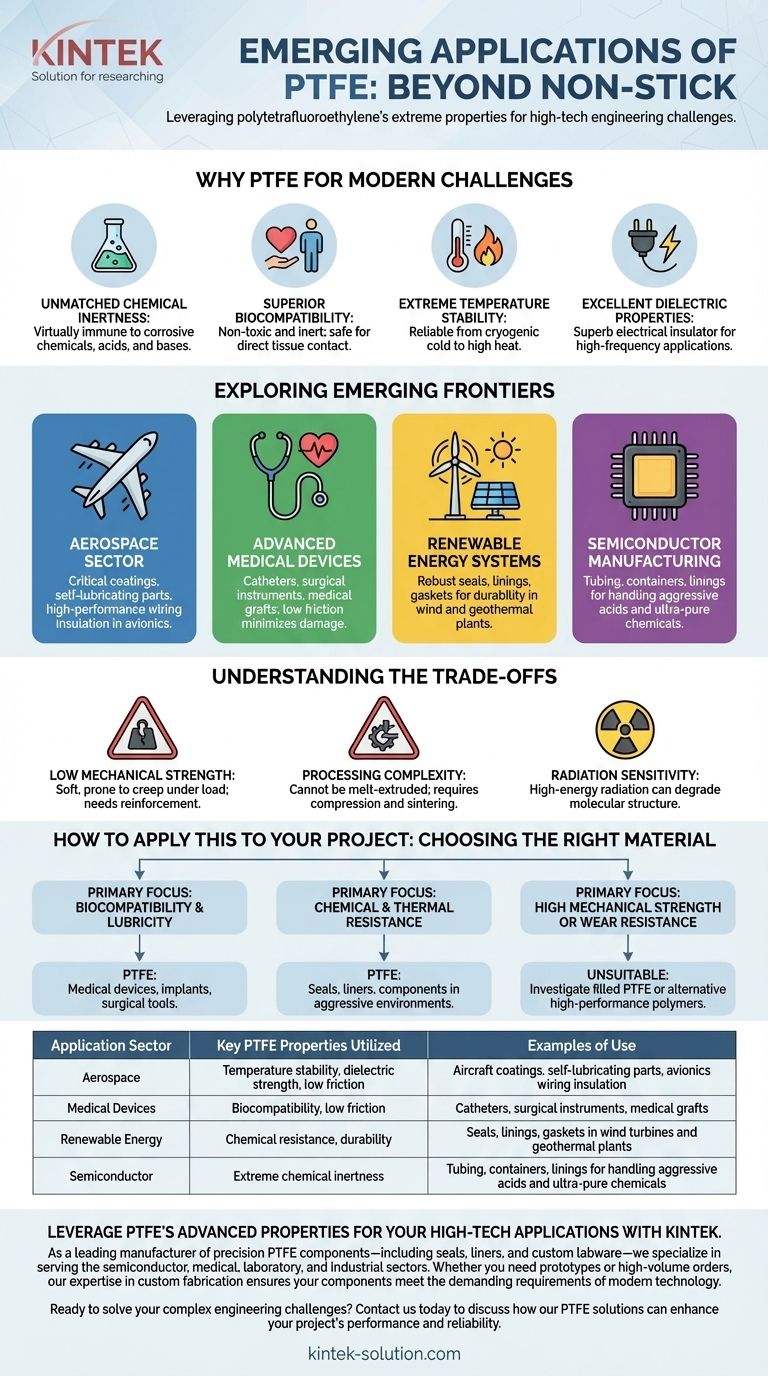

Why PTFE is a Material for Modern Challenges

Before exploring its new applications, it's crucial to understand the fundamental properties that make PTFE so valuable. These are the same traits that made it a household name, but they are being pushed to new limits in demanding environments.

Unmatched Chemical Inertness

PTFE is virtually immune to almost all chemicals, acids, and bases. This non-reactivity makes it an essential material for handling highly corrosive substances without contamination or degradation.

Superior Biocompatibility

The human body does not reject PTFE. It is non-toxic and inert, meaning it can be safely used in direct contact with tissues for extended periods, a critical factor for medical implants and devices.

Extreme Temperature Stability

PTFE maintains its properties across an exceptionally wide range of temperatures. This allows it to perform reliably in the cryogenic cold of space and the high heat of industrial or aerospace systems.

Excellent Dielectric Properties

As a superb electrical insulator, PTFE is highly effective at preventing the flow of electricity. This is especially important for high-frequency applications, such as those found in modern computer and communications wiring.

Exploring the Emerging Frontiers for PTFE

Engineers are now applying these core properties to solve problems in some of the world's most advanced industries.

The Aerospace Sector

PTFE is used for critical aircraft coatings and components. Its low friction is ideal for self-lubricating parts, while its temperature resistance is vital for components exposed to harsh engine or atmospheric conditions. Its dielectric strength makes it a top choice for insulating high-performance wiring in avionics.

Advanced Medical Devices

Biocompatibility makes PTFE a premier material for catheters, surgical instruments, and medical grafts. Its exceptionally low coefficient of friction is also a key advantage for catheters, as it minimizes damage and discomfort during insertion.

Renewable Energy Systems

To enhance durability, PTFE is used in components for renewable energy systems. It serves as robust seals, linings, and gaskets in environments like wind turbines or geothermal plants, where resistance to weathering, moisture, and corrosive fluids is paramount.

Semiconductor Manufacturing

The production of microchips involves highly aggressive acids and ultra-pure chemicals. PTFE's extreme chemical resistance makes it the ideal material for tubing, containers, and linings used in these sensitive manufacturing processes.

Understanding the Trade-offs

Despite its powerful advantages, PTFE is not a universal solution. Understanding its limitations is key to using it effectively.

Low Mechanical Strength

PTFE is a relatively soft material. It has poor resistance to wear and can deform under sustained load (a phenomenon known as "creep"). For structural applications, it often must be reinforced with fillers like glass or carbon.

Processing Complexity

Unlike many common plastics, PTFE cannot be processed using conventional melt-extrusion or injection molding techniques. It must be compressed and sintered (a high-temperature baking process), which can be more complex and costly.

Radiation Sensitivity

High-energy radiation, such as gamma rays often used for medical sterilization, can degrade the molecular structure of PTFE. This must be considered in certain space and medical applications.

How to Apply This to Your Project

Choosing the right material depends entirely on your primary engineering goal.

- If your primary focus is biocompatibility and lubricity: PTFE is a leading candidate for medical devices like catheters, implants, and surgical tools.

- If your primary focus is chemical and thermal resistance: It is an ideal material for seals, liners, and components in aggressive aerospace or semiconductor environments.

- If your primary focus is high mechanical strength or wear resistance: Pure PTFE is unsuitable, and you should investigate filled PTFE grades or alternative high-performance polymers.

Ultimately, PTFE's value lies in its ability to perform where other materials fail, making it a critical enabler of modern technology.

Summary Table:

| Application Sector | Key PTFE Properties Utilized | Examples of Use |

|---|---|---|

| Aerospace | Temperature stability, dielectric strength, low friction | Aircraft coatings, self-lubricating parts, avionics wiring insulation |

| Medical Devices | Biocompatibility, low friction | Catheters, surgical instruments, medical grafts |

| Renewable Energy | Chemical resistance, durability | Seals, linings, gaskets in wind turbines and geothermal plants |

| Semiconductor Manufacturing | Extreme chemical inertness | Tubing, containers, linings for handling aggressive acids and ultra-pure chemicals |

Leverage PTFE's advanced properties for your high-tech applications with KINTEK.

As a leading manufacturer of precision PTFE components—including seals, liners, and custom labware—we specialize in serving the semiconductor, medical, laboratory, and industrial sectors. Whether you need prototypes or high-volume orders, our expertise in custom fabrication ensures your components meet the demanding requirements of modern technology.

Ready to solve your complex engineering challenges? Contact us today to discuss how our PTFE solutions can enhance your project's performance and reliability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What is the chemical structure that gives PTFE its unique properties? The Power of the Carbon-Fluorine Bond

- Why are fillers added to PTFE? Enhance Performance for Demanding Applications

- What was one of the early uses of PTFE? From Atomic Secrets to Modern Marvels

- What services are offered to guide customers in the design and production stages of PTFE coatings? Get Expert Consultancy for Optimal Performance

- What are the common filler materials used in RPTFE and their purposes? Enhance PTFE Performance for Demanding Applications

- What are the key properties of PTFE material? A Guide to Extreme Performance

- How are fillers used to enhance PTFE properties? Boost Wear, Strength, and Thermal Performance

- What are the disadvantages of bronze bushings? Understanding the Trade-Offs for Heavy-Duty Applications