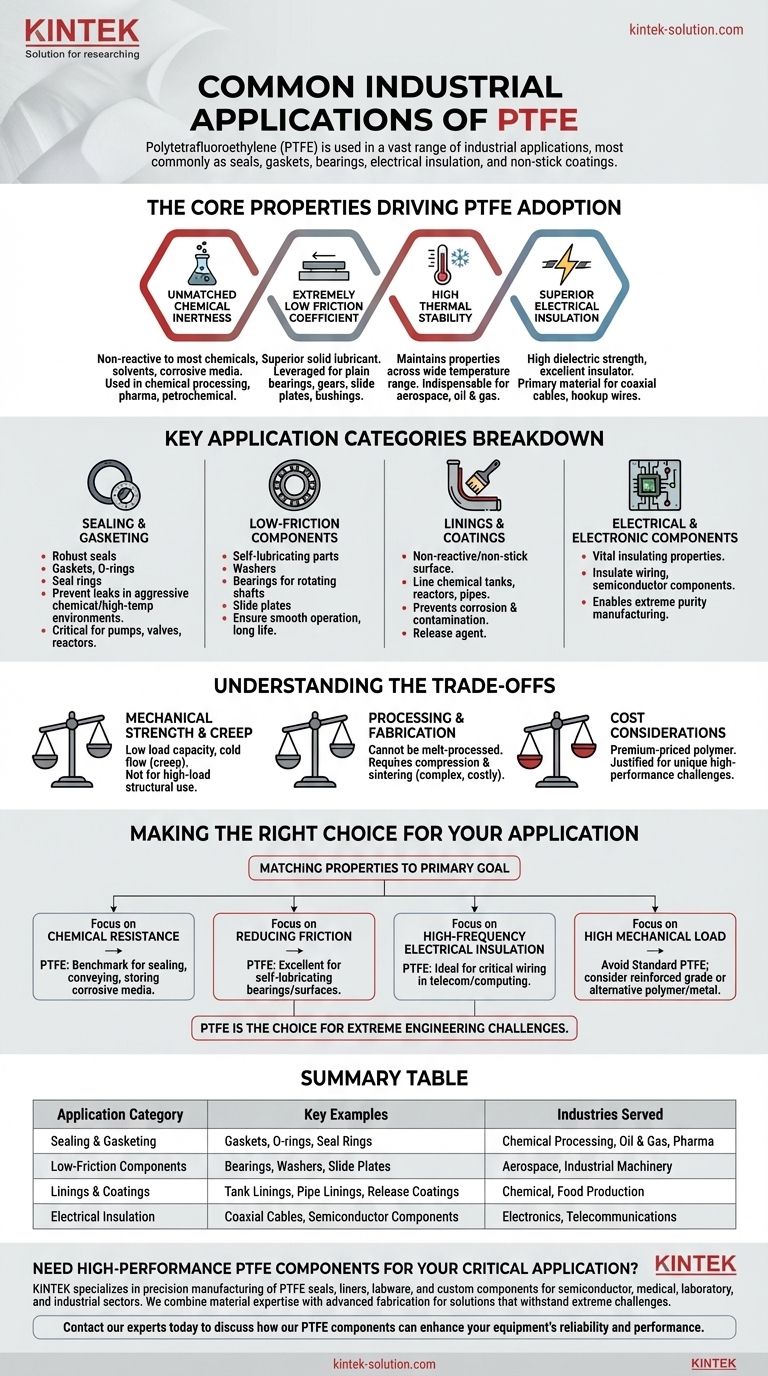

In short, Polytetrafluoroethylene (PTFE) is used in a vast range of industrial applications, most commonly as seals, gaskets, bearings, electrical insulation, and non-stick coatings. Its utility spans critical sectors including chemical processing, aerospace, oil & gas, and food production due to its unique combination of chemical inertness, low friction, and high thermal stability.

The widespread industrial use of PTFE is not due to a single feature, but its unique ability to solve problems in extreme environments where conventional materials would degrade or fail from chemical attack, high temperatures, or friction.

The Core Properties Driving PTFE Adoption

To understand why PTFE is so prevalent, you must first understand the fundamental properties that make it an elite engineering material. Its applications are a direct result of these characteristics.

Unmatched Chemical Inertness

PTFE is virtually non-reactive to almost all chemicals, solvents, and corrosive media. This makes it an essential material for handling and transporting aggressive substances.

This property is why it's specified for pipework linings, containers, and seals in the chemical processing, pharmaceutical, and petrochemical industries.

Extremely Low Friction Coefficient

PTFE has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice. It functions as a superior solid lubricant.

This is leveraged in mechanical applications like plain bearings, gears, slide plates, and bushings to reduce friction and wear between moving parts without requiring liquid lubricants.

High Thermal Stability

The material maintains its properties across a wide temperature range, performing reliably in both high-heat and cryogenic applications where other polymers would become brittle or melt.

This makes it indispensable for high-performance seals and components in the aerospace, oil & gas, and other demanding industrial sectors.

Superior Electrical Insulation

PTFE is an excellent electrical insulator with a very high dielectric strength, meaning it can withstand strong electric fields without breaking down.

Because of this, it is a primary material for insulating high-frequency coaxial cables and hookup wires used in computer and aerospace applications.

Key Application Categories Breakdown

These core properties translate into several distinct categories of industrial use.

Sealing and Gasketing

The most common application is creating robust seals. PTFE gaskets, O-rings, and seal rings prevent leaks in aggressive chemical and high-temperature environments.

They are critical components in pumps, valves, and reactors where material integrity is paramount.

Low-Friction Components

In industrial machinery, PTFE is used to create self-lubricating parts that ensure smooth operation and long service life.

Examples include washers, bearings for rotating shafts, and slide plates for structural supports that must accommodate thermal expansion.

Linings and Coatings

PTFE’s non-reactive and non-stick surface makes it a premier coating and lining material.

Beyond cookware, it is used to line chemical tanks, reactors, and pipes to prevent corrosion and product contamination. It also serves as a release agent on industrial equipment.

Electrical and Electronic Components

In the semiconductor and electronics industries, PTFE's insulating properties are vital.

It is used to insulate wiring and create components for manufacturing processes that require extreme purity and chemical resistance.

Understanding the Trade-offs

While its performance is exceptional, PTFE is not a universal solution. A true technical assessment requires understanding its limitations.

Mechanical Strength and Creep

PTFE is a relatively soft material and is not suitable for high-load structural applications. It can be susceptible to "creep" or cold flow, meaning it can deform slowly over time under a constant load.

Processing and Fabrication

PTFE cannot be melt-processed like common thermoplastics. It is typically shaped through compression and sintering, which can be more complex and costly than injection molding.

Cost Considerations

PTFE is a high-performance, premium-priced polymer. Its use is typically justified only when its unique properties are necessary to meet a specific performance challenge that commodity plastics cannot handle.

Making the Right Choice for Your Application

Selecting the right material is about matching its properties to your primary goal.

- If your primary focus is chemical resistance: PTFE is the benchmark material for sealing, conveying, or storing highly corrosive media.

- If your primary focus is reducing friction: It is an excellent choice for self-lubricating bearings and surfaces, especially where grease or oil is undesirable.

- If your primary focus is high-frequency electrical insulation: Its low dielectric constant makes it ideal for critical wiring in telecom and computing.

- If your primary focus is high mechanical load: Standard PTFE should be avoided; consider a reinforced grade or a different engineering polymer or metal.

Ultimately, PTFE is the material of choice for solving engineering challenges that are simply too extreme for anything else.

Summary Table:

| Application Category | Key Examples | Industries Served |

|---|---|---|

| Sealing & Gasketing | Gaskets, O-rings, Seal Rings | Chemical Processing, Oil & Gas, Pharma |

| Low-Friction Components | Bearings, Washers, Slide Plates | Aerospace, Industrial Machinery |

| Linings & Coatings | Tank Linings, Pipe Linings, Release Coatings | Chemical, Food Production |

| Electrical Insulation | Coaxial Cables, Semiconductor Components | Electronics, Telecommunications |

Need high-performance PTFE components for your critical application?

KINTEK specializes in the precision manufacturing of PTFE seals, liners, labware, and custom components for the semiconductor, medical, laboratory, and industrial sectors. We combine material expertise with advanced fabrication capabilities to deliver solutions that withstand extreme chemical, thermal, and friction challenges—from prototypes to high-volume production.

Contact our experts today to discuss how our PTFE components can enhance the reliability and performance of your equipment.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems