The most common Teflon back-up ring configurations are categorized into three fundamental types: solid (uncut), single turn (scarf cut), and spiral (multi-turn). While many specific product names exist, they are nearly all variations of these core designs. These rings are not seals themselves; they are engineered support components designed to prevent the failure of a primary O-ring under pressure.

The core decision in selecting a back-up ring is not about memorizing a long list of types, but about understanding a fundamental trade-off. You are balancing the need for maximum extrusion resistance against the practical need for ease of installation.

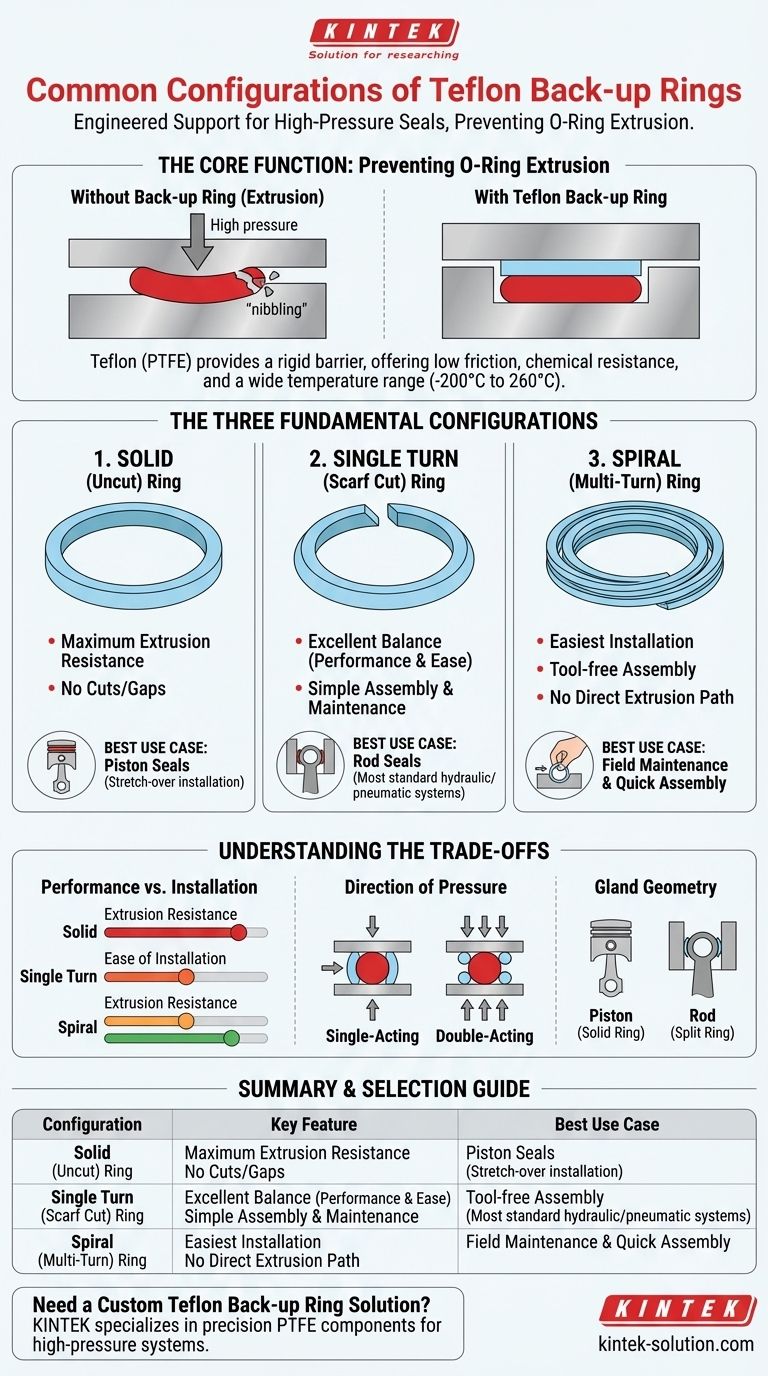

The Core Function: Preventing O-Ring Extrusion

To choose the right configuration, you must first understand the problem it solves. Back-up rings are essential in high-pressure hydraulic and pneumatic systems.

What is Extrusion?

Under high pressure, a rubber O-ring can be forced into the small clearance gap between mating metal parts. This process, known as extrusion, effectively "nibbles" away at the O-ring, leading to premature leakage and seal failure.

How Back-up Rings Solve the Problem

A back-up ring is installed on the low-pressure side of the O-ring. Because it is made from a harder material, it physically blocks the clearance gap. This provides rigid support for the O-ring, preventing it from being pushed into the gap and allowing the system to operate at much higher pressures.

Why Teflon (PTFE)?

Teflon, or PTFE, is the standard material for back-up rings due to its exceptional properties. It offers a very low coefficient of friction, broad chemical resistance, and a wide operating temperature range (-200°C to 260°C), ensuring it doesn't stick to or react with the O-ring or system components.

The Three Fundamental Configurations

Every back-up ring design is a variation of one of these three approaches, each with a distinct purpose.

The Solid (Uncut) Ring

This is a continuous, unbroken ring of Teflon. It offers the absolute best performance against extrusion because there are no cuts or potential leak paths.

Its primary limitation is installation. A solid ring must be stretched over a component, like a piston, to be seated in its groove. This makes it unsuitable for rod sealing applications where the groove is internal.

The Single Turn (Scarf Cut) Ring

This is the most common compromise. The ring is cut once, typically at a 30° or 45° angle (a "scarf cut").

This cut allows the ring to be easily opened and snapped into an internal groove for rod seals. It dramatically simplifies assembly and maintenance compared to a solid ring while still providing excellent extrusion resistance for most applications.

The Spiral (Multi-Turn) Ring

This configuration is made from two or more coils of PTFE wound like a spring.

Spiral rings are the easiest to install, often requiring no special tools. The overlapping nature of the coils eliminates the direct extrusion path found in a single-cut ring, offering a slight performance advantage in some cases while maintaining installation flexibility.

Understanding the Trade-offs

Choosing the correct back-up ring is about weighing performance requirements against assembly logistics.

Performance vs. Installation

The central trade-off is clear: Solid rings offer the highest performance but are the most difficult to install.

Spiral rings are the easiest to install, but a solid ring provides a more robust, gap-free barrier. The single turn (scarf cut) ring sits as a reliable middle ground for the vast majority of industrial applications.

Direction of Pressure

In applications where pressure is applied in only one direction, a single back-up ring is placed on the low-pressure side of the O-ring.

For double-acting systems where pressure is applied from two directions, two back-up rings are used, one on each side of the O-ring.

Gland Geometry

The physical design of your hardware is often the deciding factor. If you are sealing a piston, a solid ring can be installed. If you are sealing a rod within a bore, you must use a split ring (single turn or spiral) that can be installed in the groove.

Selecting the Right Configuration for Your Application

Use your primary goal to guide your decision.

- If your primary focus is maximum pressure resistance and durability: Choose a solid (uncut) back-up ring, provided your design allows for stretch-over installation (e.g., a piston seal).

- If your primary focus is a reliable balance of performance and ease of assembly: A single turn (scarf cut) ring is the most common and effective choice for most standard hydraulic and pneumatic systems.

- If your primary focus is rapid, tool-free installation, especially for field maintenance: The spiral (multi-turn) ring offers excellent convenience and reliable performance.

Understanding this relationship between geometry and function allows you to select the precise back-up ring for a reliable, long-lasting seal.

Summary Table:

| Configuration | Key Feature | Best Use Case |

|---|---|---|

| Solid (Uncut) | Maximum extrusion resistance; no gaps | Piston seals where stretch-over installation is possible |

| Single Turn (Scarf Cut) | Excellent balance of performance and ease of assembly | Most standard hydraulic/pneumatic systems; rod seals |

| Spiral (Multi-Turn) | Easiest installation; tool-free assembly | Field maintenance; applications requiring quick assembly |

Need a custom Teflon back-up ring solution for your high-pressure system?

At KINTEK, we specialize in manufacturing precision PTFE components, including custom back-up rings for the semiconductor, medical, laboratory, and industrial sectors. Whether you require prototypes or high-volume orders, our expertise ensures optimal performance and durability for your specific application.

Contact us today to discuss your requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments