In short, Teflon is commonly used for manufacturing chemical-resistant pipework, creating low-friction mechanical parts, coating medical and food processing equipment, and lining laboratory appliances. Formally known as Polytetrafluoroethylene (PTFE), its unique characteristics make it a critical material in industries ranging from aerospace and automotive to chemical processing and electrical engineering.

The reason for Teflon's widespread application isn't a single feature, but its rare combination of properties. Its ability to simultaneously resist aggressive chemicals, reduce friction, and withstand extreme temperatures makes it a uniquely versatile problem-solver in engineering and manufacturing.

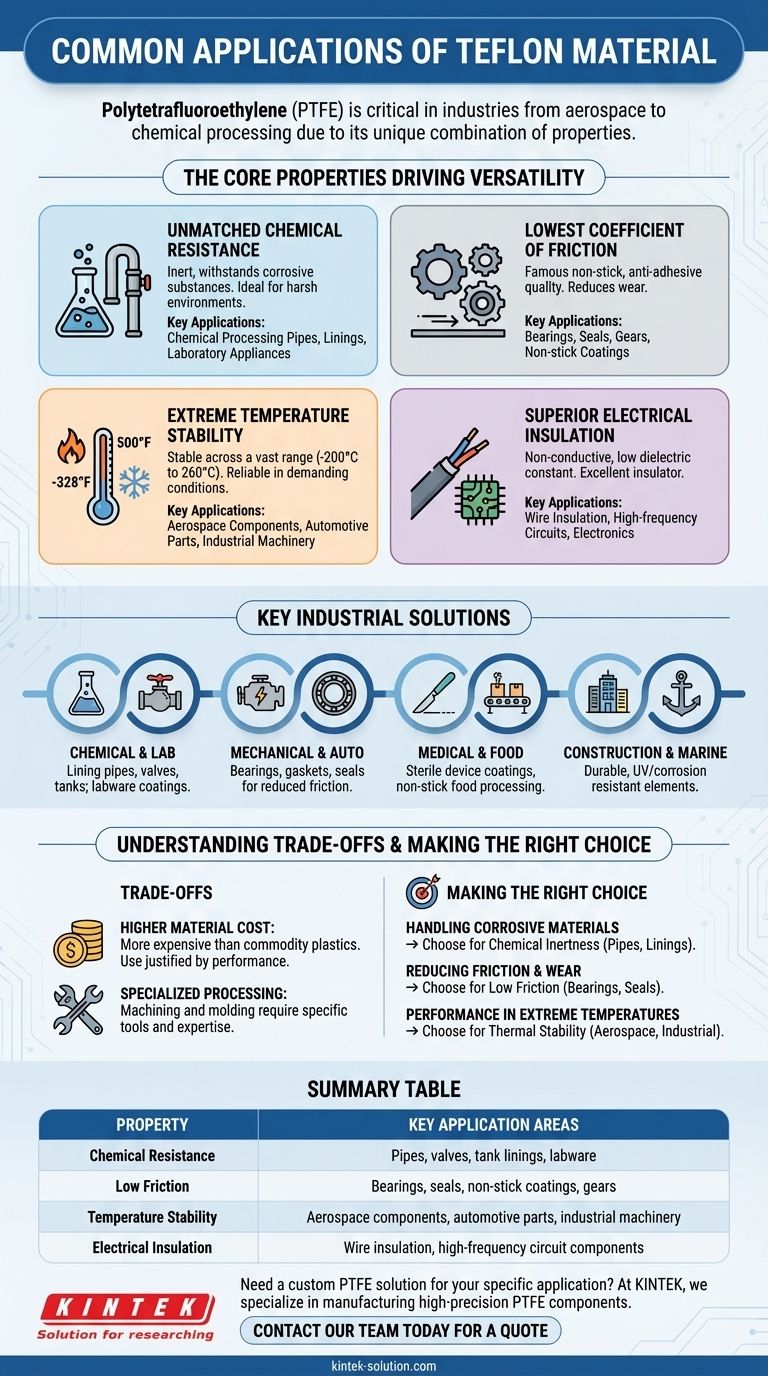

The Core Properties Driving Teflon's Versatility

To understand where Teflon is used, we must first understand why. Its applications are a direct result of its fundamental material characteristics.

Unmatched Chemical Resistance

Teflon is exceptionally non-reactive and can withstand a wide range of corrosive substances. This chemical inertness makes it invaluable in harsh environments.

This property is why it is used for pipes, linings, and containers in the chemical processing industry.

The Lowest Coefficient of Friction

PTFE has one of the lowest coefficients of friction of any known solid material, giving it its famous non-stick or anti-adhesive quality.

This is the principle behind its use in anti-friction devices, gears, slide plates, and, most famously, non-stick cookware.

Extreme Temperature Stability

The material remains stable and functional across a vast temperature range, from approximately -328°F to 500°F (-200°C to 260°C).

This thermal durability allows it to be used in demanding aerospace, automotive, and industrial machinery applications where other plastics would fail.

Superior Electrical Insulation

Teflon is an excellent electrical insulator with a very low dielectric constant. It does not conduct electricity, making it ideal for electronics.

This is why it's used in electrical engineering for things like wire insulation and components in high-frequency circuits.

A Closer Look at Key Industrial Applications

These core properties translate directly into tangible solutions across various sectors.

In Chemical and Laboratory Settings

Due to its inertness, Teflon is the material of choice for lining pipes, valves, and tanks that handle highly corrosive acids or bases. Laboratory appliances are often coated with it to prevent contamination and ensure easy cleaning.

In Mechanical and Automotive Engineering

In machines, Teflon is used for bearings, gaskets, and seals. Its low-friction nature reduces wear and tear on moving parts, increasing efficiency and the lifespan of the equipment.

In the Medical and Food Processing Fields

The non-stick and non-reactive surface is critical for hygiene. Teflon is used to coat medical instruments and devices to ensure they are sterile and biocompatible, while in food processing, it ensures that products move smoothly without sticking to machinery.

In Construction and Marine Applications

Teflon's durability, UV resistance, and corrosion resistance make it suitable for architectural elements and marine equipment exposed to harsh weather and saltwater.

Understanding the Trade-offs

While incredibly useful, PTFE is not a universal solution. Its high-performance nature comes with specific considerations.

Higher Material Cost

As a high-performance fluoropolymer, Teflon is generally more expensive than commodity plastics like polyethylene or polypropylene. Its use must be justified by the specific performance demands of the application.

Specialized Processing

Machining and molding PTFE can be more complex than other polymers. Its characteristics require specific tools and expertise to form it into finished parts effectively.

Making the Right Choice for Your Goal

Selecting Teflon is about matching its unique strengths to your primary challenge.

- If your primary focus is handling corrosive materials: Teflon's chemical inertness makes it the ideal choice for pipes, valves, and container linings that must not degrade.

- If your primary focus is reducing friction and wear: Its extremely low coefficient of friction is perfect for creating durable bearings, seals, and non-stick surfaces.

- If your primary focus is performance in extreme temperatures: Its wide functional temperature range makes it a reliable choice for demanding aerospace, automotive, and industrial processes.

Understanding these core properties empowers you to identify where this high-performance material will provide the most effective and durable solution.

Summary Table:

| Property | Key Application Areas |

|---|---|

| Chemical Resistance | Pipes, valves, tank linings, labware |

| Low Friction | Bearings, seals, non-stick coatings, gears |

| Temperature Stability | Aerospace components, automotive parts, industrial machinery |

| Electrical Insulation | Wire insulation, high-frequency circuit components |

Need a custom PTFE solution for your specific application?

At KINTEK, we specialize in manufacturing high-precision PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you require prototypes or high-volume production, our expertise in custom fabrication ensures a part that perfectly leverages Teflon's unique properties to solve your engineering challenges.

Contact our team today to discuss your project requirements and get a quote.

Visual Guide

Related Products

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

People Also Ask

- What are some exceptional properties of PTFE? Unlock Unmatched Performance in Extreme Environments

- What industrial applications does PTFE have? Unlock Performance in Extreme Environments

- Why are PTFE vials considered environmentally friendly? Reduce Lab Waste with Durable Reusables

- What are the common characteristics of Teflon? Unlocking Extreme Chemical and Thermal Resistance

- What material is the PTFE bottle made from? Discover the Benefits of 100% Virgin PTFE