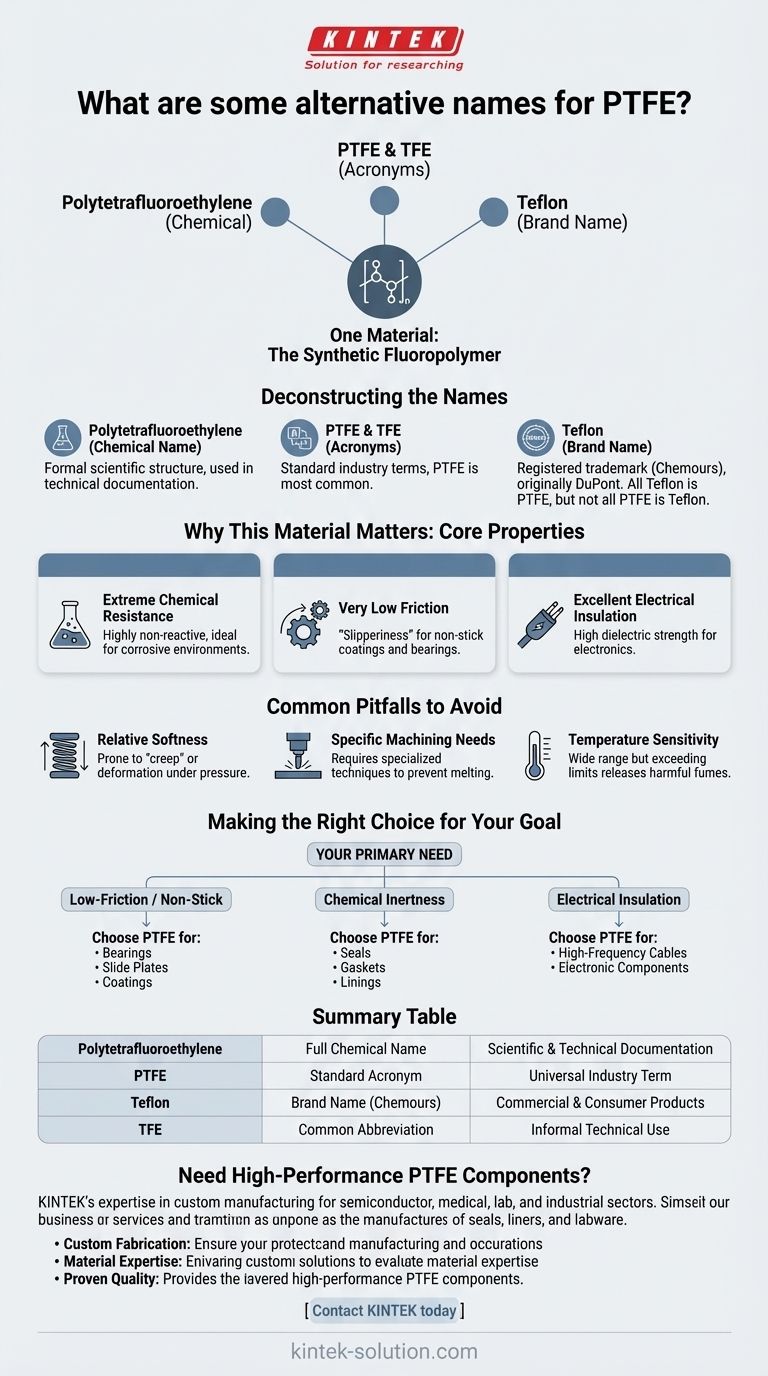

In the world of materials science, Polytetrafluoroethylene is most commonly known by its acronym PTFE, its abbreviation TFE, or its famous brand name, Teflon. These names all refer to the same highly versatile synthetic fluoropolymer, renowned for its exceptional properties.

The various names for Polytetrafluoroethylene (PTFE)—including Teflon and TFE—all describe a single material. Understanding that these are just different labels for the same polymer is the first step to leveraging its unique combination of chemical resistance, low friction, and electrical insulation.

Deconstructing the Names: Chemical vs. Brand

The different names for this material arise from scientific, industrial, and commercial contexts. Recognizing them helps you identify the material regardless of how it's referenced.

Polytetrafluoroethylene (The Chemical Name)

This is the formal, scientific name for the polymer. It describes its chemical structure and is the most precise term used in technical documentation and academic research.

PTFE & TFE (The Acronyms)

PTFE is the standard industry acronym derived directly from Polytetrafluoroethylene. It is the most common and universally understood technical abbreviation. TFE is a less common but still used abbreviation.

Teflon (The Brand Name)

Teflon is the registered trademark for PTFE, originally commercialized by DuPont and now owned by Chemours. While all Teflon is PTFE, not all PTFE is sold under the Teflon brand, similar to how not all tissues are Kleenex.

Why This Material Matters: Core Properties

Regardless of what you call it, PTFE is valued for a specific set of characteristics that make it indispensable in numerous applications.

Extreme Chemical Resistance

PTFE is highly non-reactive, making it an ideal choice for containers and pipework that handle corrosive and reactive chemicals. Its inertness prevents material degradation and contamination.

Very Low Friction

Known for its "slipperiness," PTFE has one of the lowest coefficients of friction of any solid. This property is leveraged for non-stick coatings on cookware as well as in industrial gears, slide plates, and bearings to reduce wear and energy consumption.

Excellent Electrical Insulation

PTFE is an outstanding electrical insulator with a high dielectric strength. This makes it a critical material for computer applications, including the insulation for coaxial cables and high-performance hookup wires.

Common Pitfalls to Avoid

While incredibly useful, PTFE is not a universal solution. Understanding its limitations is key to successful application.

Relative Softness

Compared to metals, PTFE is a soft material. This makes it prone to "creep" or deformation under sustained pressure, a critical consideration for structural or high-load bearing applications.

Specific Machining Needs

PTFE's softness and thermal properties require specialized machining techniques. Standard methods like CNC milling and turning must be adapted to prevent material melting or deformation during the process.

Temperature Sensitivity

While it has a wide operating temperature range, PTFE has upper and lower limits. Exceeding its thermal capacity can lead to degradation and the release of harmful fumes, a critical safety consideration.

Making the Right Choice for Your Goal

Your application's primary need will determine if PTFE is the correct material, regardless of which name you use to specify it.

- If your primary focus is low-friction or non-stick surfaces: PTFE is an excellent choice for bearings, slide plates, or specialized coatings.

- If your primary focus is chemical inertness: Its non-reactive nature makes it ideal for seals, gaskets, and lining in chemically aggressive environments.

- If your primary focus is electrical insulation: PTFE is a top-tier material for high-frequency cables and critical electronic components.

Ultimately, recognizing PTFE in all its forms empowers you to select one of the most versatile and reliable polymers available for demanding technical challenges.

Summary Table:

| Name/Abbreviation | Type | Common Context |

|---|---|---|

| Polytetrafluoroethylene | Full Chemical Name | Scientific & Technical Documentation |

| PTFE | Standard Acronym | Universal Industry Term |

| Teflon | Brand Name (Chemours) | Commercial & Consumer Products |

| TFE | Common Abbreviation | Informal Technical Use |

Need High-Performance PTFE Components?

KINTEK specializes in the precision manufacturing of custom PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. We ensure your parts leverage PTFE's full potential, from chemical resistance and low friction to superior electrical insulation.

Let us deliver the precision you need:

- Custom Fabrication: From prototypes to high-volume production.

- Material Expertise: Optimal machining to prevent deformation.

- Proven Quality: Components built for demanding environments.

Contact KINTEK today to discuss your project requirements and get a quote.

Visual Guide

Related Products

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- How does PTFE react to common solvents? Discover Its Near-Total Chemical Immunity

- How was PTFE discovered and developed? From Lab Accident to Essential High-Performance Polymer

- What is Teflon and what is its chemical name? Unpacking the Science of PTFE

- When was PTFE discovered and developed? The Accidental Invention That Changed Industries

- What are the similarities between PTFE and RPTFE? Unlocking the Core Fluoropolymer Identity