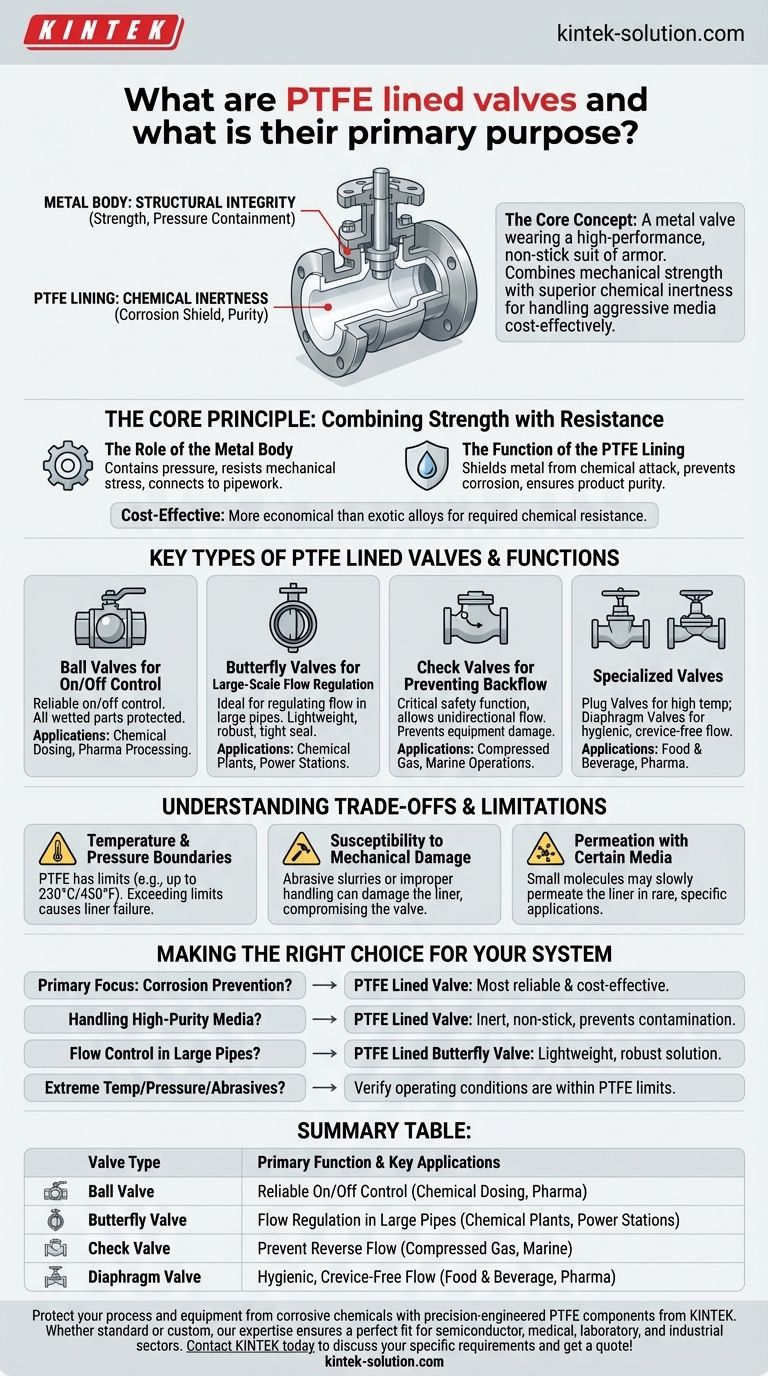

In essence, a PTFE lined valve is a standard metal valve wearing a high-performance, non-stick suit of armor. It is a valve with a robust metal body—typically cast iron, ductile iron, or stainless steel—whose internal surfaces are completely coated with a thick layer of Polytetrafluoroethylene (PTFE). The primary purpose of this design is to provide exceptional corrosion resistance, creating an inert barrier that protects the valve's structural components from aggressive chemicals, acids, and high-purity media.

The core concept behind a PTFE lined valve is simple but powerful: it combines the mechanical strength and pressure-containing capability of metal with the superior chemical inertness of PTFE. This makes it a cost-effective and highly reliable solution for safely handling fluids that would quickly degrade standard metal valves.

The Core Principle: Combining Strength with Resistance

To fully appreciate the value of these components, it's essential to understand how the two primary materials work in concert. Each serves a distinct but critical function.

The Role of the Metal Body

The exterior metal body provides the valve's structural integrity. It is responsible for containing system pressure, resisting mechanical stress, and connecting securely to the surrounding pipework. Without this metal shell, the valve could not withstand the rigors of most industrial applications.

The Function of the PTFE Lining

The internal PTFE lining is the component that comes into direct contact with the process fluid. PTFE is a fluoropolymer known for its extreme chemical inertness and non-stick properties. Its sole job is to shield the metal body from chemical attack, preventing corrosion and ensuring product purity.

Why This Combination is Cost-Effective

Using a PTFE lined valve is often more economical than constructing the entire valve from an expensive exotic alloy, such as Hastelloy or Titanium. This composite design delivers the necessary chemical resistance for the application without the high cost of a full-body alloy valve, providing a durable, long-term solution.

Key Types of PTFE Lined Valves and Their Functions

Different valve designs are lined with PTFE to suit specific operational needs, from simple on/off control to flow regulation in large pipelines.

Ball Valves for On/Off Control

A PTFE lined ball valve is the go-to choice for reliable on/off control of corrosive fluids. The rotating ball is also lined, ensuring that all wetted parts are protected from the media. They are commonly found in chemical dosing systems and pharmaceutical processing.

Butterfly Valves for Large-Scale Flow Regulation

For regulating or isolating flow in large-diameter pipes, the PTFE lined butterfly valve is ideal. Its lightweight yet robust design provides a tight seal, while the lining ensures excellent resistance to chemical attack in applications like chemical plants and power stations.

Check Valves for Preventing Backflow

A PTFE lined check valve serves a critical safety function by allowing fluid to flow in only one direction. This prevents reverse flow that could damage pumps and other upstream equipment, making it essential in compressed gas units and marine operations.

Specialized Valves for Niche Applications

Other designs exist for specific needs. PTFE lined plug valves are often used in high-temperature services, while PTFE lined diaphragm valves feature a crevice-free design perfect for hygienic processes in the food, beverage, and pharmaceutical industries.

Understanding the Trade-offs and Limitations

While highly effective, PTFE lined valves are not a universal solution. Understanding their limitations is key to proper application and avoiding failure.

Temperature and Pressure Boundaries

PTFE is a polymer and has clear temperature and pressure limits that are lower than those of solid metal. While it has high thermal stability for a polymer (often up to 230°C / 450°F), exceeding these manufacturer-specified limits can cause the liner to fail.

Susceptibility to Mechanical Damage

The PTFE liner can be damaged by highly abrasive slurries or improper installation and maintenance. A scratch or gouge in the liner can create a path for corrosive media to reach the metal body, compromising the entire valve.

Permeation with Certain Media

In rare, highly specific applications, very small molecules (like certain gases or acids) can slowly permeate through the polymer liner over time. This is a niche concern but is critical to consider when handling extremely aggressive or dangerous media under high pressure.

Making the Right Choice for Your System

Selecting the correct valve requires aligning the component's capabilities with the demands of your process.

- If your primary focus is corrosion prevention for aggressive chemicals: A PTFE lined valve is almost always the most reliable and cost-effective choice over standard metal valves.

- If you are handling high-purity media: The inert, non-stick surface of a PTFE lined valve is ideal for preventing fluid contamination and buildup.

- If your system involves flow control in large pipes: A PTFE lined butterfly valve provides a lightweight, robust, and chemically resistant solution.

- If your process involves extreme temperatures, pressures, or abrasives: You must carefully verify that your operating conditions are well within the specified limits of the valve's PTFE liner.

Ultimately, choosing a PTFE lined valve is an investment in your system's long-term safety, reliability, and integrity when facing chemically challenging media.

Summary Table:

| Valve Type | Primary Function | Key Applications |

|---|---|---|

| Ball Valve | Reliable On/Off Control | Chemical Dosing, Pharmaceutical Processing |

| Butterfly Valve | Flow Regulation in Large Pipes | Chemical Plants, Power Stations |

| Check Valve | Prevent Reverse Flow (Backflow) | Compressed Gas Units, Marine Operations |

| Diaphragm Valve | Hygienic, Crevice-Free Flow | Food & Beverage, Pharmaceutical Industries |

Protect your process and equipment from corrosive chemicals with precision-engineered PTFE components from KINTEK.

Whether you need standard PTFE lined valves or custom-fabricated seals, liners, and labware, our expertise ensures a perfect fit for your application in the semiconductor, medical, laboratory, and industrial sectors. We handle everything from prototypes to high-volume production.

Contact KINTEK today to discuss your specific requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers