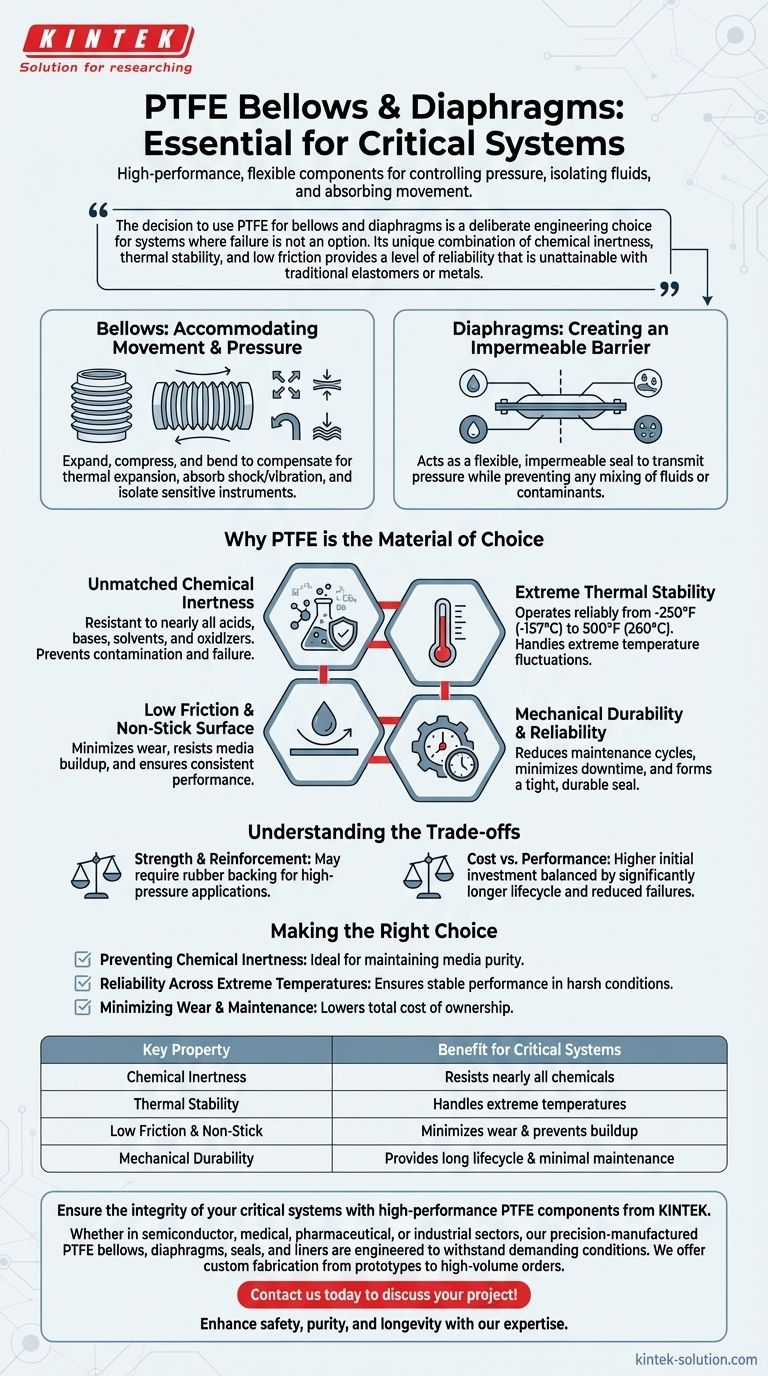

In short, PTFE bellows and diaphragms are high-performance, flexible components essential for controlling pressure, isolating fluids, and absorbing movement in demanding industrial environments. Their importance stems from the unique properties of Polytetrafluoroethylene (PTFE), which allows them to operate reliably in conditions where nearly all other materials would fail, ensuring the safety and integrity of critical systems.

The decision to use PTFE for bellows and diaphragms is a deliberate engineering choice for systems where failure is not an option. Its unique combination of chemical inertness, thermal stability, and low friction provides a level of reliability that is unattainable with traditional elastomers or metals.

The Core Function of Flexible Components

To understand why PTFE is so critical, we must first understand the roles these components play. They are not static parts; they are designed to move, flex, and respond to system dynamics.

Bellows: Accommodating Movement and Pressure

PTFE bellows have an accordion-like design that allows them to expand, compress, and bend. This flexibility is crucial for compensating for thermal expansion, absorbing shock and vibration, and isolating sensitive instruments from system stresses.

Diaphragms: Creating an Impermeable Barrier

A PTFE diaphragm acts as a flexible, impermeable seal between two chambers. Its primary function is to transmit pressure while preventing any mixing of fluids or contaminants, which is vital for maintaining media purity and system safety.

Why PTFE is the Material of Choice

The performance of bellows and diaphragms is defined entirely by the material they are made from. PTFE offers a set of properties that make it uniquely suited for the most hostile operating conditions.

Unmatched Chemical Inertness

PTFE is resistant to nearly all industrial chemicals, including aggressive acids, bases, solvents, and oxidizers. This makes it the default choice for chemical processing and semiconductor manufacturing, where component degradation could lead to catastrophic failure or product contamination.

Extreme Thermal Stability

These components maintain their integrity and flexibility across an exceptionally wide temperature range, from cryogenic lows of -250°F (-157°C) to high-heat applications exceeding 500°F (260°C). This stability is essential for aerospace, defense, and industrial systems that experience severe temperature fluctuations.

Inherent Low Friction and Non-Stick Surface

PTFE has one of the lowest coefficients of friction of any solid, minimizing wear and tear during repeated movement. Its non-adhesive surface resists the buildup of process media, ensuring consistent performance and preventing contamination in pharmaceutical and medical applications.

Mechanical Durability and Reliability

The material's resilience reduces the frequency of maintenance and replacement, which minimizes costly downtime. Its ability to form a tight, durable seal prevents leaks, ensuring both the safety and the operational efficiency of the system.

Understanding the Trade-offs

While PTFE offers exceptional performance, it is important to recognize its operational context. Its selection is a solution for specific, high-stakes challenges.

Strength and Reinforcement

PTFE is not as rigid as metal. In high-pressure applications, a diaphragm may require a rubber or elastomeric backing to provide additional mechanical strength and resilience, combining the chemical resistance of PTFE with the structural integrity of another material.

Cost vs. Performance

PTFE components represent a higher initial investment compared to those made from standard elastomers. However, this cost is justified by their significantly longer lifecycle, reduced maintenance needs, and the prevention of failures in systems where the consequences would be far more expensive.

Making the Right Choice for Your System

Selecting the right component is about matching its capabilities to the primary demands of your application.

- If your primary focus is preventing chemical contamination: PTFE's inertness and non-adhesive surface make it the definitive choice for maintaining media purity.

- If your primary focus is reliability across extreme temperatures: PTFE's wide operating range ensures stable and predictable performance where other materials would become brittle or degrade.

- If your primary focus is minimizing wear and maintenance: The low-friction, durable nature of PTFE reduces replacement cycles, lowering the total cost of ownership over the system's life.

Ultimately, selecting PTFE bellows and diaphragms is a strategic investment in the safety, purity, and longevity of your most critical systems.

Summary Table:

| Key Property | Benefit for Critical Systems |

|---|---|

| Chemical Inertness | Resists nearly all acids, bases, and solvents, preventing contamination and failure. |

| Thermal Stability | Operates reliably from -250°F to 500°F, handling extreme temperature fluctuations. |

| Low Friction & Non-Stick | Minimizes wear and prevents media buildup, ensuring consistent performance. |

| Mechanical Durability | Provides a long lifecycle with minimal maintenance, reducing costly downtime. |

Ensure the integrity of your critical systems with high-performance PTFE components from KINTEK.

Whether you are in the semiconductor, medical, pharmaceutical, or industrial sector, our precision-manufactured PTFE bellows, diaphragms, seals, and liners are engineered to withstand your most demanding operating conditions. We offer custom fabrication from prototypes to high-volume orders, ensuring a perfect fit for your application's unique requirements.

Contact us today to discuss your project and discover how our expertise can enhance the safety, purity, and longevity of your systems.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE and Nitrile Diaphragm Pump Components for Demanding Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications