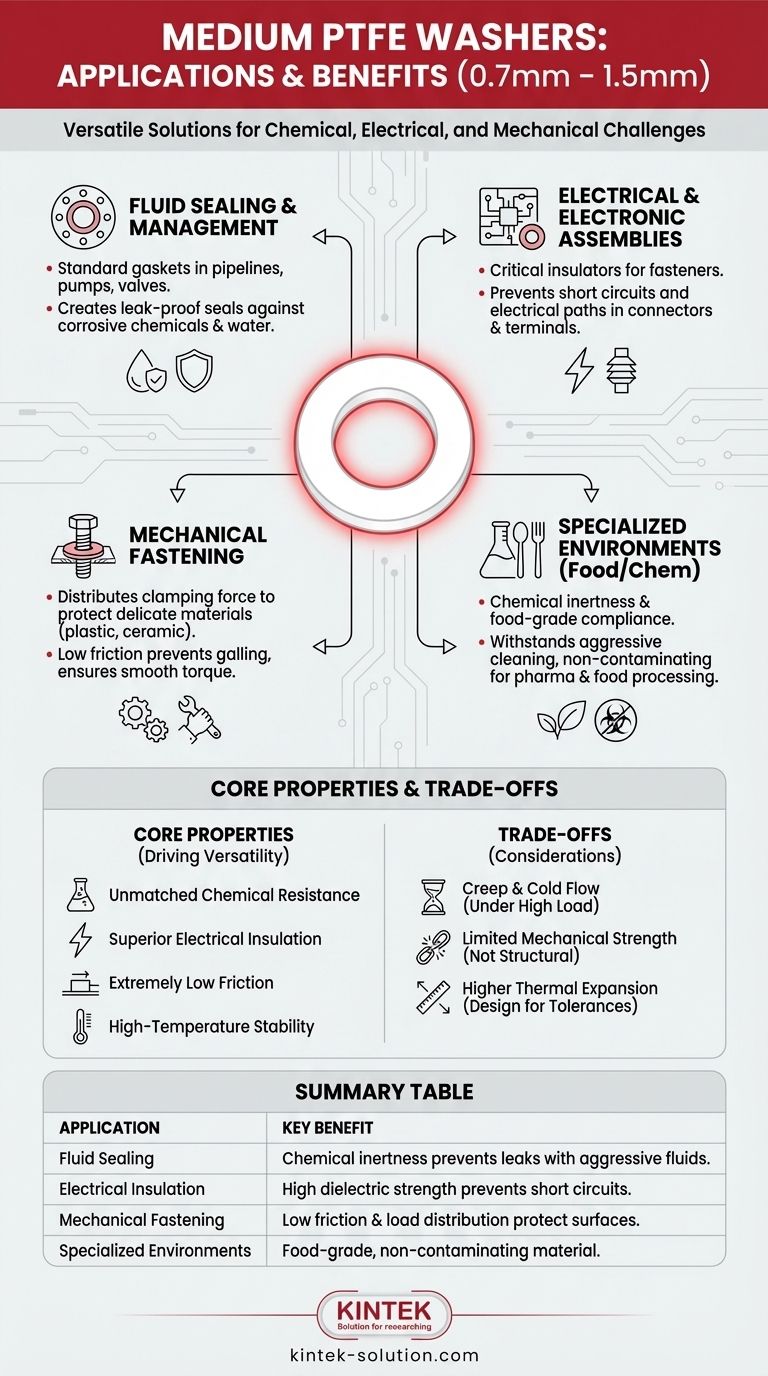

In short, medium PTFE washers are exceptionally versatile components used as standard gaskets in fluid systems, corrosion-resistant barriers in chemical processing, and critical insulators in electrical assemblies. Their utility stems from a unique combination of chemical inertness, low friction, and excellent dielectric properties, making them a go-to solution in demanding industrial environments.

The core reason to select a medium PTFE washer is not for its mechanical strength, but for its ability to solve problems where other materials fail due to chemical attack, electrical conductivity, or friction.

Core Properties Driving PTFE's Versatility

To understand where to apply these washers, you must first understand the material itself. PTFE's effectiveness is rooted in a few key characteristics that make it unlike most other polymers or metals.

Unmatched Chemical Resistance

PTFE is virtually inert to almost all industrial chemicals, acids, and solvents. This makes it an ideal material for creating a barrier or seal in equipment that handles corrosive substances, from chemical processing plants to aggressive cleaning cycles in the food industry.

Superior Electrical Insulation

PTFE is an excellent electrical insulator with a high dielectric strength. It does not conduct electricity, which is critical for preventing short circuits in electronic devices and ensuring safety in high-voltage systems.

Extremely Low Friction

Known for its non-stick, self-lubricating properties, PTFE has one of the lowest coefficients of friction of any solid material. This allows it to be used in mechanical assemblies to reduce friction between components or to distribute the load from a screw or bolt without damaging delicate surfaces.

High-Temperature Stability

PTFE washers maintain their integrity and properties across a wide range of temperatures. This stability is crucial for performance in applications that experience significant temperature fluctuations, from heated industrial pipelines to electronic components that generate heat.

Key Industrial Applications for Medium Washers

The 0.7mm to 1.5mm thickness range represents a standard, all-purpose dimension suitable for the most common industrial challenges.

Fluid Sealing and Management

The most frequent application is as a gasket or seal. In pipelines, pumps, and valves, a medium PTFE washer conforms to flange surfaces to create a tight, leak-proof seal that is impervious to the fluid being transported, whether it's water or a harsh chemical.

Electrical and Electronic Assemblies

PTFE washers are used to electrically isolate fasteners (like screws and bolts) from a chassis or other conductive components. They are placed in electrical connectors, terminals, and mounting hardware to prevent electrical current from finding an unintended path.

Mechanical Fastening and Assembly

In mechanical joints, these washers serve a dual purpose. They distribute the clamping force of a fastener over a wider area, which is vital when fastening to soft or brittle surfaces like plastic or ceramic. Their low friction also prevents galling and ensures smooth, consistent torqueing.

Specialized Environments: Chemical and Food Processing

Due to its chemical inertness and availability in food-grade materials, PTFE is indispensable in these sectors. It can withstand aggressive industrial cleaning agents and will not contaminate the processed products, making it ideal for equipment used in food, beverage, and pharmaceutical manufacturing.

Understanding the Trade-offs

While incredibly useful, PTFE is not a universal solution. An expert advisor must point out its limitations to ensure proper application.

Creep and Cold Flow

PTFE is a relatively soft material. Under a high, constant compressive load, it can slowly deform over time, a phenomenon known as "creep" or "cold flow." This must be accounted for in high-pressure sealing or high-torque bolted applications.

Limited Mechanical Strength

PTFE washers are not structural components. They should never be used where high tensile or shear strength is required. They are designed for sealing, insulating, and reducing friction, not for load-bearing in the way a hardened steel washer is.

Higher Thermal Expansion

Compared to metals, PTFE expands and contracts more significantly with temperature changes. In assemblies with tight tolerances and wide operating temperature ranges, this difference in thermal expansion must be considered during the design phase to avoid component failure.

Making the Right Choice for Your Application

Use this framework to determine if a medium PTFE washer is the correct component for your specific goal.

- If your primary focus is preventing leaks in aggressive chemical or fluid systems: PTFE is an excellent choice for its superior sealing capability and chemical inertness.

- If your primary focus is electrical isolation and safety: A PTFE washer is the ideal component for insulating fasteners and preventing short circuits in electrical assemblies.

- If your primary focus is protecting surfaces and ensuring smooth fastening: PTFE provides excellent load distribution and a low-friction surface for use against delicate materials.

- If your primary focus is compliance in food, beverage, or pharmaceutical processing: Food-grade PTFE washers provide a safe, non-contaminating, and durable solution.

Ultimately, a medium PTFE washer is a versatile problem-solver, chosen for its unique material properties when standard metallic or rubber components are not sufficient.

Summary Table:

| Application | Key Benefit of PTFE Washer |

|---|---|

| Fluid Sealing | Chemical inertness prevents leaks with aggressive fluids. |

| Electrical Insulation | High dielectric strength prevents short circuits. |

| Mechanical Fastening | Low friction and load distribution protect surfaces. |

| Specialized Environments | Food-grade, non-contaminating material for compliance. |

Need a reliable, high-performance PTFE component for your application?

KINTEK specializes in manufacturing precision PTFE components, including washers, seals, liners, and custom labware. We serve the semiconductor, medical, laboratory, and industrial sectors, offering custom fabrication from prototypes to high-volume orders.

Our expertise ensures you get a component that delivers superior chemical resistance, electrical insulation, and performance in demanding environments.

Contact KINTEK today to discuss your specific requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications