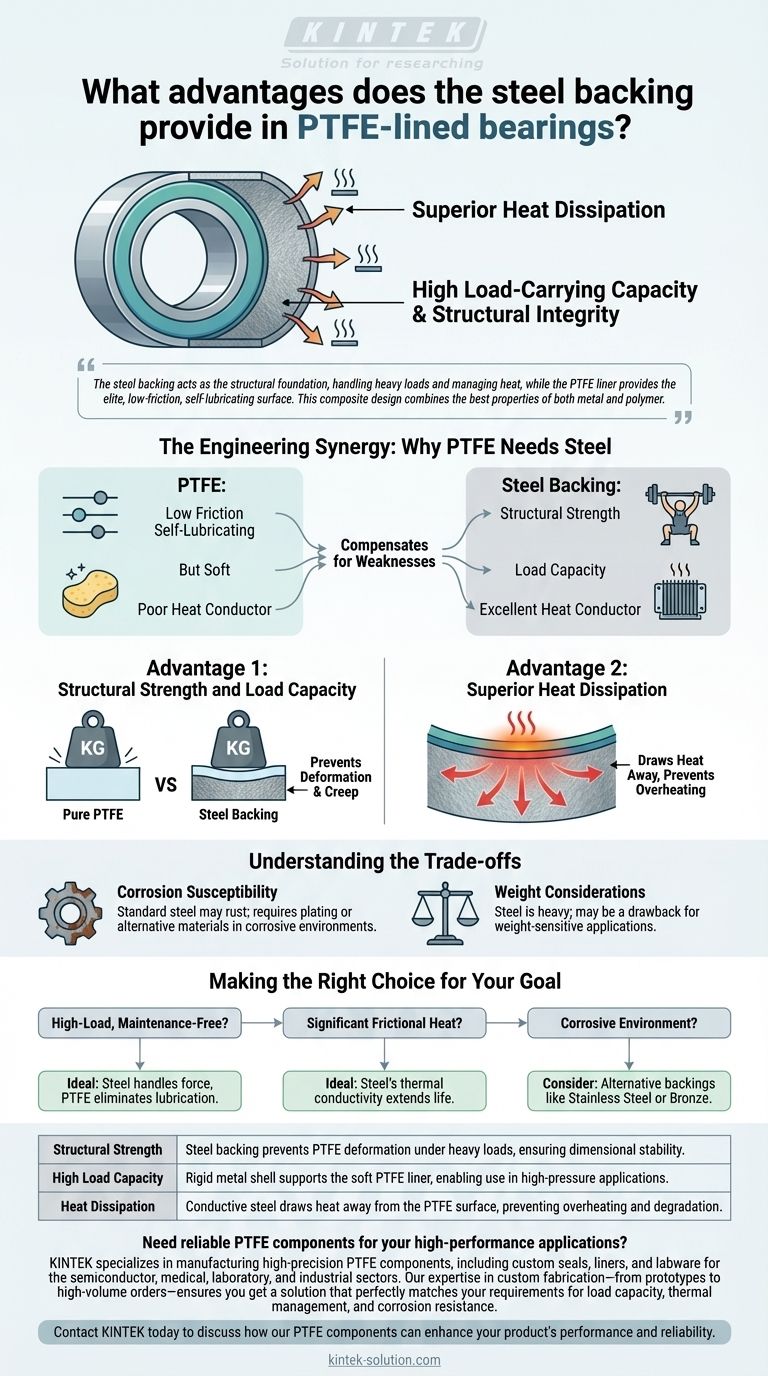

The primary advantages of a steel backing in PTFE-lined bearings are its ability to provide high load-carrying capacity and superior heat dissipation. This metal foundation gives the bearing assembly a structural integrity and thermal stability that the soft PTFE liner cannot achieve on its own.

The steel backing acts as the structural foundation, handling heavy loads and managing heat, while the PTFE liner provides the elite, low-friction, self-lubricating surface. This composite design combines the best properties of both metal and polymer.

The Engineering Synergy: Why PTFE Needs Steel

To understand the value of the steel backing, we must first look at the properties of the two materials involved. They are chosen specifically to compensate for each other's weaknesses.

The Challenge with Pure PTFE

Polytetrafluoroethylene (PTFE) has an exceptionally low coefficient of friction and is self-lubricating, making it a perfect material for a sliding surface.

However, as a polymer, it is mechanically soft. On its own, it can deform under heavy loads (a process known as creep) and is a poor conductor of heat.

Advantage 1: Structural Strength and Load Capacity

The rigid steel backing provides the bearing's foundational strength.

This metal shell prevents the softer PTFE layer from deforming, squeezing out, or failing under high pressure and heavy loads, ensuring dimensional stability.

Advantage 2: Superior Heat Dissipation

Friction, even with low-friction materials, generates heat at the sliding surface.

PTFE is a thermal insulator, meaning it traps heat. The highly conductive steel backing draws this heat away from the surface and dissipates it into the housing, preventing the PTFE from overheating and degrading.

Understanding the Trade-offs

While this composite design is highly effective, it's important to be aware of its limitations. Understanding these trade-offs ensures you select the right component for your specific application.

Corrosion Susceptibility

A standard carbon steel backing is susceptible to rust and corrosion.

In humid, wet, or chemically aggressive environments, a steel-backed bearing may require protective plating or the use of an alternative backing material like stainless steel or bronze.

Weight Considerations

Steel is a dense, heavy material.

For applications where minimizing weight is a critical design factor, such as in aerospace or high-performance robotics, the mass of a steel-backed bearing might be a significant drawback.

Making the Right Choice for Your Goal

Selecting the correct bearing depends entirely on the demands of your specific application.

- If your primary focus is high-load, maintenance-free operation: This bearing is ideal, as the steel handles the structural forces while the PTFE eliminates the need for external lubrication.

- If your application generates significant frictional heat: The steel backing's excellent thermal conductivity is a critical advantage for maintaining performance and extending bearing life.

- If you are operating in a corrosive environment: You must consider bearings with alternative backings like stainless steel or bronze to prevent failure of the support structure.

Ultimately, this composite design delivers a high-performance solution that a single material could never achieve alone.

Summary Table:

| Advantage | Description |

|---|---|

| Structural Strength | Steel backing prevents PTFE deformation under heavy loads, ensuring dimensional stability. |

| High Load Capacity | Rigid metal shell supports the soft PTFE liner, enabling use in high-pressure applications. |

| Heat Dissipation | Conductive steel draws heat away from the PTFE surface, preventing overheating and degradation. |

Need reliable PTFE components for your high-performance applications?

KINTEK specializes in manufacturing high-precision PTFE components, including custom seals, liners, and labware for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures you get a solution that perfectly matches your requirements for load capacity, thermal management, and corrosion resistance.

Contact KINTEK today to discuss how our PTFE components can enhance your product's performance and reliability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What industries benefit most from custom PTFE parts? Solve Extreme Environment Challenges

- What are FEP and PTFE encapsulated O-rings? Superior Seals for Harsh Chemical & Thermal Environments

- What are the key advantages of PTFE oil scraper rings? Superior Sealing, Low Friction & Durability

- Why is PTFE considered the best material for heavy-duty cable liners? Achieve Superior Reliability & Efficiency

- How is PTFE applied in electronics and semiconductor manufacturing? Ensure Purity and Performance

- How are control valves customized for different processes? Tailor Performance for Your Application

- What are the different forms of PTFE used for manufacturing gaskets and seals? Choose the Right Material for Your Application

- How do PTFE seals perform in chemically aggressive environments? Ensure Unmatched Chemical Resistance